I-Carbide yeSilicon eluhlaza

Ulwazi lweMveliso

Isanti ye-silicon carbide eluhlazasisiqholo esenziwe ngumntu esinefomyula yekhemikhali yeSiC. Yenziwe kakhulu ngesanti ye-quartz, i-petroleum coke (okanye i-coal coke) kunye nothuli lwesarha ngokunyibilikisa obushushu obuphezulu kwisithando sokumelana. Isanti eluhlaza ye-silicon carbide inombala oluhlaza okwesibhakabhaka.kwaye ineempawu ezininzi ezibalulekileyo kunye nezicelo.

Ukusebenza kokucubungula

Ukusebenza kakuhle kokugaya okuphezulu:Ubume besuntswana kunye nobunzima benza ukuba ibe nokusebenza kakuhle kokusila, okunokususa ngokukhawuleza ukungcola kunye nomaleko we-oxide kumphezulu wesixhobo somsebenzi.

Ipropati elungileyo yokuzilola:Ubungakanani kunye nemilo yeesuntswana ziyalingana kwaye zinomphetho weblade, oqinisekisa ukuba iyakwazi ukuzilola ngokwayo njengesixhobo seblade yokusika kwaye iqinisekisa ukuncitshiswa kwezinto ezisikiweyo.

Ukulungelelaniswa kakuhle:Ingalungelelaniswa kakuhle neendidi ezahlukeneyo zolwelo lokusika ukuphucula ukusebenza kakuhle kunye nomgangatho wokucubungula.

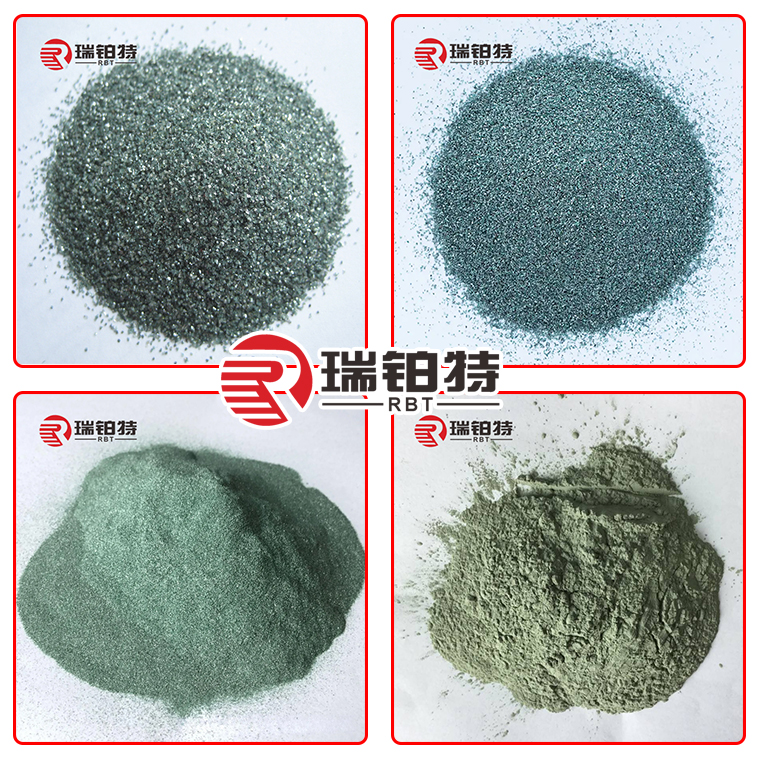

Iimpawu zePhysical

| Umbala | Luhlaza |

| Ifomu yekristale | I-Polygon |

| Ubunzima beMohs | 9.2-9.6 |

| Ubunzima obuncinci | 2840~3320kg/mm² |

| Indawo yokunyibilika | 1723 |

| Ubushushu obuphezulu bokuSebenza | 1600 |

| Uxinano Lokwenyani | 3.21g/cm³ |

| Unizi lolwapho kuyiwa khona | 2.30g/cm³ |

Iinkcukacha Imifanekiso

Itshati yokuthelekisa ubungakanani begrit

| Inombolo yeGrit | I-China GB2477-83 | I-JISR yaseJapan 6001-87 | I-USA ANSI(76) | 欧洲磨料 FEPA(84) | I-国际ISO(86) |

| 4 | 5600-4750 |

| 5600-4750 | 5600-4750 | 5600-4750 |

| 5 | 4750-4000 |

| 4750-4000 | 4750-4000 | 4750-4000 |

| 6 | 4000-3350 |

| 4000-3350 | 4000-3350 | 4000-3350 |

| 7 | 3350-2800 |

| 3350-2800 | 3350-2800 | 3350-2800 |

| 8 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 |

| 10 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 |

| 12 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 |

| 14 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 |

| 16 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 |

| 20 | 1180-1000 | 1180-1100 | 1180-1000 | 1180-1000 | 1180-1000 |

| 22 | 1000-850 | - | - | 1000-850 | 1000-850 |

| 24 | 850-710 | 850-710 | 850-710 | 850-710 | 850-710 |

| 30 | 710-600 | 710-600 | 710-600 | 710-600 | 710-600 |

| 36 | 600-500 | 600-500 | 600-500 | 600-500 | 600-500 |

| 40 | 500-425 | - | - | 500-425 | 500-425 |

| 46 | 425-355 | 425-355 | 425-355 | 425-355 | 425-355 |

| 54 | 355-300 | 355-300 | 355-297 | 355-300 | 355-300 |

| 60 | 300-250 | 300-250 | 297-250 | 300-250 | 300-250 |

| 70 | 250-212 | 250-212 | 250-212 | 250-212 | 250-212 |

| 80 | 212-180 | 212-180 | 212-180 | 212-180 | 212-180 |

| 90 | 180-150 | 180-150 | 180-150 | 180-150 | 180-150 |

| 100 | 150-125 | 150-125 | 150-125 | 150-125 | 150-125 |

| 120 | 125-106 | 125-106 | 125-106 | 125-106 | 125-106 |

| 150 | 106-75 | 106-75 | 106-75 | 106-75 | 106-75 |

| 180 | 90-63 | 90-63 | 90-63 | 90-63 | 90-63 |

| 220 | 75-53 | 75-53 | 75-53 | 75-53 | 75-53 |

| 240 | 75-53 | - | 75-53 | - |

Isalathiso seMveliso

| Ubungakanani beGrit | Ukwakheka kweeKhemikhali% (Ngobunzima) | ||

| I-SiC | F·C | I-Fe2O3 | |

| 12#-90# | ≥98.50 | ≤0.20 | ≤0.60 |

| 100#-180# | ≥98.00 | ≤0.30 | ≤0.80 |

| 220#-240# | ≥97.00 | ≤0.30 | ≤1.20 |

| I-W63-W20 | ≥96.00 | ≤0.40 | ≤1.50 |

| I-W14-W5 | ≥93.00 | ≤0.40 | ≤1.70 |

Isicelo

1. Irhabaxa:I-carbon carbide eluhlaza isetyenziswa kakhulu njengesixhobo sokurhawuzelela kwimizi-mveliso eyahlukeneyo, kuquka iimoto, i-aerospace, ukusebenza ngesinyithi, kunye nobucwebe. Isetyenziselwa ukugaya, ukusika, kunye nokupolisha izinyithi eziqinileyo kunye neeseramikhi.

2. I-Refractory:I-carbon carbide eluhlaza ikwasetyenziswa njengesixhobo esikhuselayo kwizicelo zobushushu obuphezulu ezifana nee-oven kunye nee-oven ngenxa yokuqhuba kwayo ubushushu obuphezulu kunye nokwanda kobushushu obuphantsi.

3. Izixhobo zombane:I-carbon carbide eluhlaza isetyenziswa njengesixhobo sokuxhasa izixhobo ze-elektroniki ezifana nee-LED, izixhobo zamandla, kunye nezixhobo ze-microwave ngenxa yokuqhuba kwayo umbane okugqwesileyo kunye nokuzinza kobushushu.

4. Amandla elanga:I-silicon carbide eluhlaza isetyenziswa njengezinto zokwenza iiphaneli zelanga ngenxa yokuba inamandla aphezulu okuqhuba ubushushu kunye nokwanda okuphantsi kobushushu, nto leyo enceda ekupheliseni ubushushu obuveliswa ngexesha lokusebenza kweephaneli zelanga.

5. I-Metallurgy:I-silicon carbide eluhlaza isetyenziswa njenge-deoxidizing agent ekuvelisweni kwesinyithi nentsimbi. Inceda ekususeni ukungcola kwisinyithi esinyibilikisiweyo kunye nokuphucula umgangatho wemveliso yokugqibela.

6. Iiseramikhi:I-carbon carbide eluhlaza isetyenziswa njengezinto zokwenza izinto zeseramikhi eziphambili ezifana nezixhobo zokusika, iindawo ezinganyangekiyo, kunye nezinto ezishushu kakhulu ngenxa yobunzima bayo obuphezulu, amandla aphezulu, kunye nokuzinza okugqwesileyo kobushushu.

Iphakheji kunye neNdawo yokugcina impahla

| Iphakheji | Ingxowa ye-25KG | Ingxowa ye-1000KG |

| Ubungakanani | Iitoni ezingama-24-25 | Iitoni ezingama-24 |

Iprofayile yekhampani

I-Shandong Robert New Material Co., Ltd.ikwiSixeko saseZibo, kwiPhondo laseShandong, eTshayina, elisisiseko semveliso yezinto ezinganyangekiyo. Silishishini lanamhlanje elidibanisa uphando nophuhliso, imveliso, ukuthengisa, uyilo lwe-oven kunye nolwakhiwo, iteknoloji, kunye nezixhobo ezinganyangekiyo ezithunyelwa kwamanye amazwe. Sinezixhobo ezipheleleyo, iteknoloji ephucukileyo, amandla obuchwephesha aqinileyo, umgangatho wemveliso ogqwesileyo, kunye nodumo oluhle. Umzi-mveliso wethu ugubungela iihektare ezingaphezu kwama-200 kwaye imveliso yonyaka yezixhobo ezinganyangekiyo ezimile imalunga neetoni ezingama-30000 kwaye izinto ezinganyangekiyo ezimile ziitoni ezili-12000.

Iimveliso zethu eziphambili zezinto ezichasene ne-refractory ziquka:izixhobo zokuchasana ne-alkaline; izixhobo zokuchasana ne-silicon ye-aluminium; izixhobo zokuchasana ezingamiliyo; izixhobo zokuchasana ne-thermal insulation; izixhobo ezikhethekileyo zokuchasana ne-refractory; izixhobo zokuchasana ezisebenzayo kwiinkqubo zokuphosa eziqhubekayo.

Imibuzo ebuzwa qho

Ngaba ufuna uncedo? Qiniseka ukuba undwendwela iiforam zethu zenkxaso ukuze ufumane iimpendulo kwimibuzo yakho!

Singumvelisi wokwenyani, umzi-mveliso wethu ugxile ekuveliseni izinto ezichasene nendalo kangangeminyaka engaphezu kwama-30. Sithembisa ukubonelela ngexabiso elifanelekileyo, eyona nkonzo ingcono ngaphambi kokuthengisa nasemva kokuthengisa.

Kwinkqubo nganye yemveliso, i-RBT inenkqubo epheleleyo ye-QC yokwakheka kweekhemikhali kunye neempawu zomzimba. Kwaye siza kuvavanya iimpahla, kwaye isatifikethi somgangatho siya kuthunyelwa kunye neempahla. Ukuba uneemfuno ezizodwa, siza kuzama konke okusemandleni ethu ukuzilungiselela.

Ngokuxhomekeke kubungakanani, ixesha lethu lokuhambisa lahlukile. Kodwa sithembisa ukuthumela ngokukhawuleza kangangoko kunokwenzeka ngomgangatho oqinisekisiweyo.

Kakade ke, sinikezela ngeesampuli zasimahla.

Ewe, ewe, wamkelekile ukutyelela inkampani ye-RBT kunye neemveliso zethu.

Akukho mda, singakunika ingcebiso nesisombululo esifanelekileyo ngokwemeko yakho.

Besisenza izinto ezirhabaxa kangangeminyaka engaphezu kwama-30, sinenkxaso yobugcisa enamandla kunye namava amaninzi, singanceda abathengi ukuba bayile ii-kiln ezahlukeneyo kwaye banikezele ngenkonzo enye.