Izitena zeMullite eziBunzima obuKhanyayo

Ulwazi lweMveliso

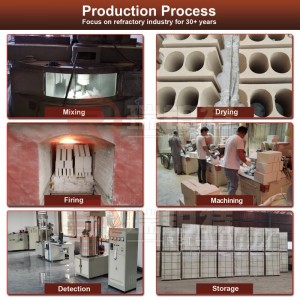

Izinto eziphambili zeizitena ze-mullite ezilulaziquka i-aluminium oxide (Al₂O₃) kunye ne-silicon dioxide (SiO₂), kwaye i-crystal phase yayo ephambili yi-mullite (3Al₂O₃·2SiO₂). Ngexesha lenkqubo yokuvelisa, i-ejenti yokufutha kunye ne-stabilizer zihlala zisetyenziselwa ukuxuba i-slurry, kwaye emva kokugalela, ukunyanga, ukomisa, ukubhaka kunye nokutshisa, ekugqibeleni kwenziwa isitena esikhaphukhaphu esine-porosity ephezulu.

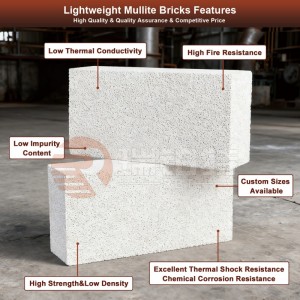

Iimbonakalo:

Ukunganyangeki okuphezulu:Ukurhawuzelelwa kwe-refractoriness kudla ngokudlula i-1600°C, okugcina iipropati zomzimba nezekhemikhali zizinzile kwiindawo ezinobushushu obuphezulu.

Ukuqhuba okuphantsi kobushushu:Ngenxa yesakhiwo sayo esilula, ukuhanjiswa kwayo kobushushu kuphantsi, ngesiqhelo yi-0.1-0.2 W/(m·K), okunciphisa ngempumelelo ukulahleka kobushushu kunye nokuphucula ukusebenza kakuhle kwamandla obushushu.

Amandla aphezulu kunye noxinano oluphantsi:Ubuninzi bomzimba buhlala buphakathi kwe-0.5-1.3 g/cm³, nto leyo enciphisa ubunzima bomzimba ngelixa igcina amandla aphezulu.

Ukumelana kakuhle nobushushu:Iyamelana nokuguquguquka okukhawulezileyo kobushushu, iyamelana nokuqhekeka ngexesha lokuqalisa rhoqo kwe-oven kunye nokuvalwa, kwaye igcina uzinzo lwesakhiwo.

Ukumelana neekhemikhali:Ukumelana kakuhle ne-asidi kunye ne-alkaline slags kunye neegesi, okuvumela ukusetyenziswa ixesha elide kwiindawo ezirhabaxa.

Umxholo wokungcola ophantsi:Izinto eziluhlaza ezicocekileyo kakhulu zisetyenziswa kwinkqubo yemveliso, nto leyo ebangela ukuba kubekho ukungcola okuncinci, nto leyo enciphisa ukungcola kwemveliso kwiindawo ezinobushushu obuphezulu.

Isalathiso seMveliso

| ISALATHISO | I-JM-23 | I-JM-25 | I-JM-26 | I-JM-27 | I-JM-28 | I-JM-30 | I-JM-32 | |

| Ubuninzi bobuninzi (g/cm3) ≥ | 0.6 | 0.8 | 0.8 | 1.0 | 1.0 | 1.2 | 1.2 | |

| Amandla okutyumza abandayo (MPa) ≥ | 1.0 | 1.5 | 2 | 2.5 | 2.5 | 3.0 | 3.5 | |

| Utshintsho olusisigxina lwe-Linear ≤1% ℃×12h | Ubushushu bovavanyo | 1230 | 1350 | 1400 | 1450 | 1510 | 1620 | 1730 |

| I-Xmin-Xmax | -1.5-0.5 | |||||||

| I-0.05MPa Ukungaguquguquki komthwalo phantsi komthwalo T0.3/℃ ≥ | 1080 | 1200 | 1250 | 1300 | 1360 | 1470 | 1570 | |

| Ukuqhuba kwe-Thermal (W/mk) | 200℃ | 0.18 | 0.26 | 0.28 | 0.32 | 0.35 | 0.42 | 0.56 |

| 350℃ | 0.20 | 0.28 | 0.30 | 0.34 | 0.37 | 0.44 | 0.60 | |

| 600℃ | 0.22 | 0.30 | 0.33 | 0.36 | 0.39 | 0.46 | 0.64 | |

| I-Al2O3(%) ≥ | 45 | 50 | 55 | 60 | 65 | 70 | 77 | |

| I-Fe2O3(%) ≤ | 1.0 | 1.0 | 0.9 | 0.8 | 0.7 | 0.6 | 0.5 | |

Isicelo

Iifurnace ezishushu kakhulu:Isetyenziswa kwiilinings ze-oven, iitop ze-oven, ii-nozzles ze-oven kunye nezinye iindawo ukuphucula isiphumo sokukhusela izixhobo kunye nokunciphisa ukusetyenziswa kwamandla.

Ishishini lePetrochemical:Isetyenziswa ekuveliseni izinto ezibalulekileyo ezifana nee-catalysts, ii-heat exchangers, ii-reactors, njl.njl., ukuphucula ukumelana namaqondo obushushu aphezulu kunye nokuguguleka.

Imboni yeglasi kunye noshishino lweceramic:isetyenziswa kwii-oven zeglasi ezinyibilikisayo nakwii-oven ze-tunnel ukuphucula ubomi benkonzo kunye nokusebenza kakuhle kwemveliso yezi-oven.

Ishishini lamandla ombane:isetyenziselwa ukuthintela izixhobo kwizikhululo zamandla ezishushu, kwizikhululo zamandla enyukliya nakwezinye iindawo ukuqinisekisa ukusebenza ngokukhuselekileyo kwezibonelelo zamandla.

I-Aerospace:isetyenziselwa ukukhusela izixhobo ezishushu kakhulu ezifana neenjini zerokethi kunye neenjini zejethi ukuphucula ukusebenza kwezixhobo.

Iifurnace ezishushu kakhulu

Imboni yeglasi

Ishishini lePetrochemical

Ishishini leCeramic

Ishishini lamandla ombane

I-Aerospace

Iprofayile yekhampani

I-Shandong Robert New Material Co., Ltd.ikwiSixeko saseZibo, kwiPhondo laseShandong, eTshayina, elisisiseko semveliso yezinto ezinganyangekiyo. Silishishini lanamhlanje elidibanisa uphando nophuhliso, imveliso, ukuthengisa, uyilo lwe-oven kunye nolwakhiwo, iteknoloji, kunye nezixhobo ezinganyangekiyo ezithunyelwa kwamanye amazwe. Sinezixhobo ezipheleleyo, iteknoloji ephucukileyo, amandla obuchwephesha aqinileyo, umgangatho wemveliso ogqwesileyo, kunye nodumo oluhle. Umzi-mveliso wethu ugubungela iihektare ezingaphezu kwama-200 kwaye imveliso yonyaka yezixhobo ezinganyangekiyo ezimile imalunga neetoni ezingama-30000 kwaye izinto ezinganyangekiyo ezimile ziitoni ezili-12000.

Iimveliso zethu eziphambili zezinto ezichasene ne-refractory ziquka:izixhobo zokuchasana ne-alkaline; izixhobo zokuchasana ne-silicon ye-aluminium; izixhobo zokuchasana ezingamiliyo; izixhobo zokuchasana ne-thermal insulation; izixhobo ezikhethekileyo zokuchasana ne-refractory; izixhobo zokuchasana ezisebenzayo kwiinkqubo zokuphosa eziqhubekayo.

Iimveliso zikaRobert zisetyenziswa kakhulu kwii-oven ezishushu kakhulu ezifana neentsimbi ezingenayo i-ferrous, intsimbi, izixhobo zokwakha kunye nolwakhiwo, iikhemikhali, amandla ombane, ukutshisa inkunkuma, kunye nonyango lwenkunkuma enobungozi. Zikwasetyenziswa kwiinkqubo zentsimbi kunye nesinyithi ezifana neeladle, i-EAF, ii-blast furnaces, ii-converters, ii-oven ze-coke, ii-hot blast furnaces; ii-oven ze-metallurgical ezingenayo i-ferrous ezifana nee-reverberators, ii-reduction furnaces, ii-blast furnaces, kunye nee-rotary furnaces; izixhobo zokwakha ii-oven zoshishino ezifana nee-glass furnaces, ii-cement furnaces, kunye nee-ceramic furnaces; ezinye ii-oven ezifana nee-boilers, ii-waste incinerators, i-roasting furnace, ezifumene iziphumo ezilungileyo ekusebenziseni. Iimveliso zethu zithunyelwa kwi-Southeast Asia, Central Asia, Middle East, Afrika, Europe, Americas nakwamanye amazwe, kwaye ziseke isiseko esihle sentsebenziswano namashishini amaninzi entsimbi aziwayo. Bonke abasebenzi bakaRobert bajonge phambili ngokunyanisekileyo ekusebenzeni nani kwimeko ephumelela kumacala omabini.

Imibuzo ebuzwa qho

Ngaba ufuna uncedo? Qiniseka ukuba undwendwela iiforam zethu zenkxaso ukuze ufumane iimpendulo kwimibuzo yakho!

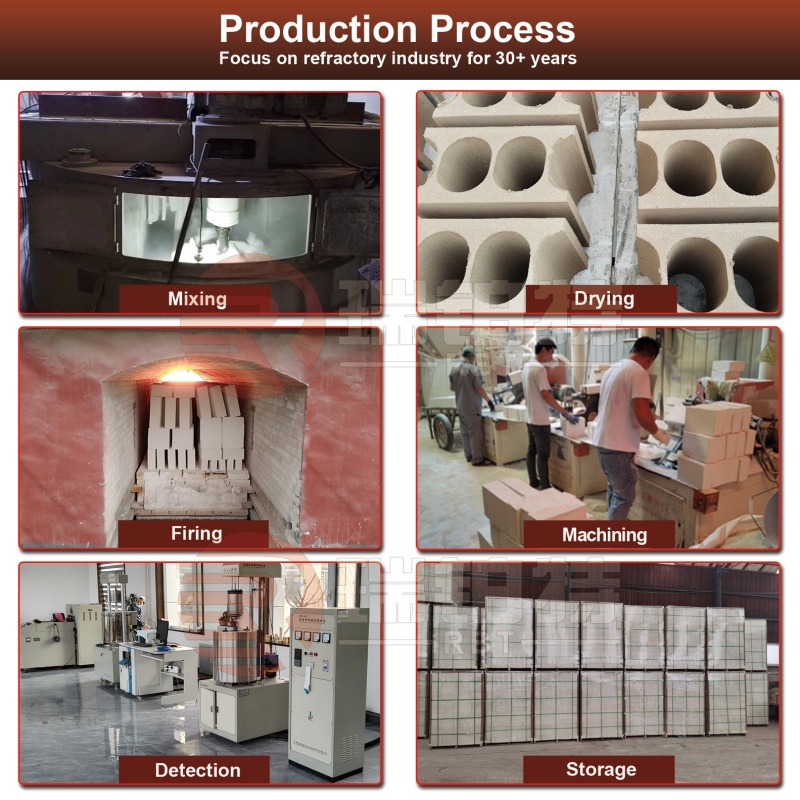

Singumvelisi wokwenyani, umzi-mveliso wethu ugxile ekuveliseni izinto ezichasene nendalo kangangeminyaka engaphezu kwama-30. Sithembisa ukubonelela ngexabiso elifanelekileyo, eyona nkonzo ingcono ngaphambi kokuthengisa nasemva kokuthengisa.

Kwinkqubo nganye yemveliso, i-RBT inenkqubo epheleleyo ye-QC yokwakheka kweekhemikhali kunye neempawu zomzimba. Kwaye siza kuvavanya iimpahla, kwaye isatifikethi somgangatho siya kuthunyelwa kunye neempahla. Ukuba uneemfuno ezizodwa, siza kuzama konke okusemandleni ethu ukuzilungiselela.

Ngokuxhomekeke kubungakanani, ixesha lethu lokuhambisa lahlukile. Kodwa sithembisa ukuthumela ngokukhawuleza kangangoko kunokwenzeka ngomgangatho oqinisekisiweyo.

Kakade ke, sinikezela ngeesampuli zasimahla.

Ewe, ewe, wamkelekile ukutyelela inkampani ye-RBT kunye neemveliso zethu.

Akukho mda, singakunika ingcebiso nesisombululo esifanelekileyo ngokwemeko yakho.

Besisenza izinto ezirhabaxa kangangeminyaka engaphezu kwama-30, sinenkxaso yobugcisa enamandla kunye namava amaninzi, singanceda abathengi ukuba bayile ii-kiln ezahlukeneyo kwaye banikezele ngenkonzo enye.