Izitena zeMullite

Malunga nezitena zeMullite

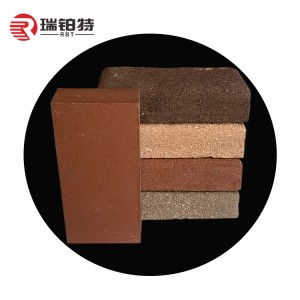

Izitena ze-Mullite ziyi-aluminiyam ephezulu ephikisayo ene-mullite njengenqanaba lekristale eliphambili.Ngokuqhelekileyo, umxholo we-alumina uphakathi kwe-65% kunye ne-75%.Ukongeza kwi-mullite, amaminerali anomxholo ophantsi we-alumina nawo aqulethe inani elincinci le-vitreous phase kunye ne-cristobalite.Umxholo ophezulu we-alumina uqulethe ixabiso elincinci le-corundum.

Izitena zeMullite zine-refractoriness ephezulu, enokufikelela ngaphezulu kwe-1790 °C.Ubushushu besiqalo sokuthambisa umthwalo yi-1600℃~1700℃.Amandla oxinzelelo kwiqondo lokushisa legumbi yi-70-260MPa.Ukumelana kakuhle nokothuka kwe-thermal.

Kukho iindidi ezimbini zezitena ze-mullite ezidityanisiweyo kunye nezitena ezixutyiweyo ze-mullite.

Izitena ze-mullite ze-Sintered zenziwe nge-high-alumina bauxite clinker njengeyona nto iphambili eluhlaza, yongeza inani elincinci lodongwe okanye i-bauxite eluhlaza njenge-binder, kwaye yenziwe kwaye igxothwe.Izitena ze-mullite ezixutywe zenziwe nge-bauxite ephezulu, i-alumina ye-industrial kunye nodongwe olunqabileyo, kunye ne-charcoal okanye i-coke particles emihle yongezwa njenge-arhente yokunciphisa.Emva kokubumba, zenziwa ngokunciphisa i-electrofusion.

I-crystallization ye-mullite edibeneyo inkulu kune-sintered mullite, kwaye ukuxhathisa ukothuka kwe-thermal kungcono kunemveliso ye-sintered.Ukusebenza kwabo okuphezulu kweqondo lokushisa kuxhomekeke kumxholo we-alumina kunye nokufana kokusabalalisa kwesigaba se-mullite kunye neglasi.

Izitena ze-Mullite zisetyenziselwa ubukhulu becala kwisitovu somlilo oshushu, umzimba wesithando somlilo kunye nezantsi, i-glass furnace regenerator, i-ceramic kiln, i-dead corner lineing ye-petroleum cracking system, njl.

Malunga neSillimanite

Izitena ze-sillimanite zinozinzo oluhle lwe-thermal kwiqondo lokushisa eliphezulu, ukuchasana nokukhukuliseka kolwelo lweglasi, ukungcola okuncinci kulwelo lweglasi.

Ikakhulu ifanelekile kwitshaneli yokutya, umatshini wokutyisa, umatshini wokutsala ityhubhu kunye nezinye izixhobo kwishishini leglasi, elinokuphucula kakhulu imveliso.

Ikakhulu ifanelekile kwitshaneli yokutya, umatshini wokutyisa, umatshini wokutsala ityhubhu kunye nezinye izixhobo kwishishini leglasi, elinokuphucula kakhulu imveliso.

Isalathiso seMveliso

| INDEX | I-mullite ephantsi kathathu | Sintered mullite | I-Sillimanite | I-mullite edibeneyo | ||||

| I-RBTM-47 | I-RBTM-65 | I-RBTM-70 | I-RBT-M75 | I-RBTM-80 | I-RBTA-60 | I-RBTFM-75 | ||

| I-Refractoriness (℃) ≥ | 1790 | 1790 | 1790 | 1790 | 1810 | 1790 | 1810 | |

| Ubuninzi Bobuninzi (g/cm3) ≥ | 2.42 | 2.45 | 2.50 | 2.60 | 2.70 | 2.48 | 2.70 | |

| I-Porosity ebonakalayo (%) ≤ | 12 | 18 | 18 | 17 | 17 | 18 | 16 | |

| Amandla Okutyumza Okubandayo(MPa) ≥ | 60 | 60 | 70 | 80 | 85 | 65 | 90 | |

| Utshintsho olusisigxina lomgca (%) | 1400°×2h | +0.1 -0.1 |

|

|

|

|

|

|

| 1500°×2h |

| +0.1 -0.4 | +0.1 -0.4 | +0.1 -0.4 | +0.1 -0.4 | +1 -0.2 | ±0.1 | |

| I-Refractoriness Under Load @0.2MPa (℃)≥ | 1520 | 1580 | 1600 | 1600 | 1620 | 1600 | 1700 | |

| Isantya sokuGquqa @0.2MPa 1200°×2h(%) ≤ | 0.1 | ― | ― | ― | ― | ― | ― | |

| Al2O3(%) ≥ | 47 | 64 | 68 | 72 | 78 | 60 | 75 | |

| Fe2O3(%) ≤ | 1.2 | 0.8 | 0.8 | 0.7 | 0.7 | 1.0 | 0.5 | |