Ukuthatha iglasi edadayo njengomzekelo, izixhobo ezintathu eziphambili zobushushu kwimveliso yeglasi ziquka isithando sokunyibilikisa iglasi edadayo, isithando sokuhlambela iglasi edadayo kunye nesithando sokutshisa iglasi. Kwinkqubo yokuvelisa iglasi, isithando sokutshisa iglasi sinoxanduva lokunyibilikisa izinto zebhetshi zibe lulwelo lweglasi kwaye sicacise, sizilungise size sizipholise kubushushu obufunekayo bokubumba. Isithando sokuhlambela sesinyithi sisixhobo esiphambili sokubumba iglasi. Ulwelo lweglasi olunobushushu obuyi-1050 ~ 1100℃ luhamba ukusuka kumjelo wokuhamba ukuya kumphezulu wolwelo lwesinyithi kwindawo yokuhlamba isinyithi. Ulwelo lweglasi luyacaba kwaye lupholishwe kumphezulu webhafu yesinyithi, kwaye lulawulwa kukutsala ngoomatshini, ii-side guards kunye noomatshini bokuzoba ecaleni ukwenza iribhoni yeglasi enobubanzi nobukhulu obufunekayo. Kwaye ishiya ibhafu yesinyithi xa iphola kancinci ukuya kwi-600℃ ngexesha lenkqubo yokuya phambili. Umsebenzi wesithando sokutshisa kukususa uxinzelelo olushiyekileyo kunye nokungalingani kweglasi edadayo, kunye nokuzinzisa isakhiwo sangaphakathi seglasi. Iribhoni yeglasi eqhubekayo enobushushu obuyi-600℃ obubangelwa yibhafu yesinyithi ingena kwisithando sokutshisa ngetafile yerola yokutshintsha. Zonke ezi zixhobo zintathu ziphambili zobushushu zifuna izinto ezichasene nobushushu. Ukuqinisekisa ukusebenza okuqhelekileyo nokuzinzileyo kwesithando sokunyibilikisa iglasi, ngokwenene asinakwahlulwa kuncedo lwezinto ezahlukeneyo ezichasene nobushushu. Ezi zilandelayo ziintlobo ezili-9 zezinto ezichasene nobushushu ezisetyenziswa kakhulu kwizithando zokunyibilikisa iglasi kunye neempawu zazo:

Izitena zesilika zee-oven zeglasi:

Izithako eziphambili: i-silicon dioxide (i-SiO2), umxholo kufuneka ube ngaphezulu kwama-94%. Ubushushu bokusebenza: ubushushu obuphezulu bokusebenza yi-1600 ~ 1650℃. Iimpawu: ukumelana kakuhle nokukhukuliseka kwe-asidi ye-slag, kodwa ukumelana kakubi nokukhukuliseka kwezinto ezibhabhayo ze-alkaline. Isetyenziselwa ikakhulu ukwakhiwa kwee-arches ezinkulu, iindonga zesifuba kunye nee-oven ezincinci.

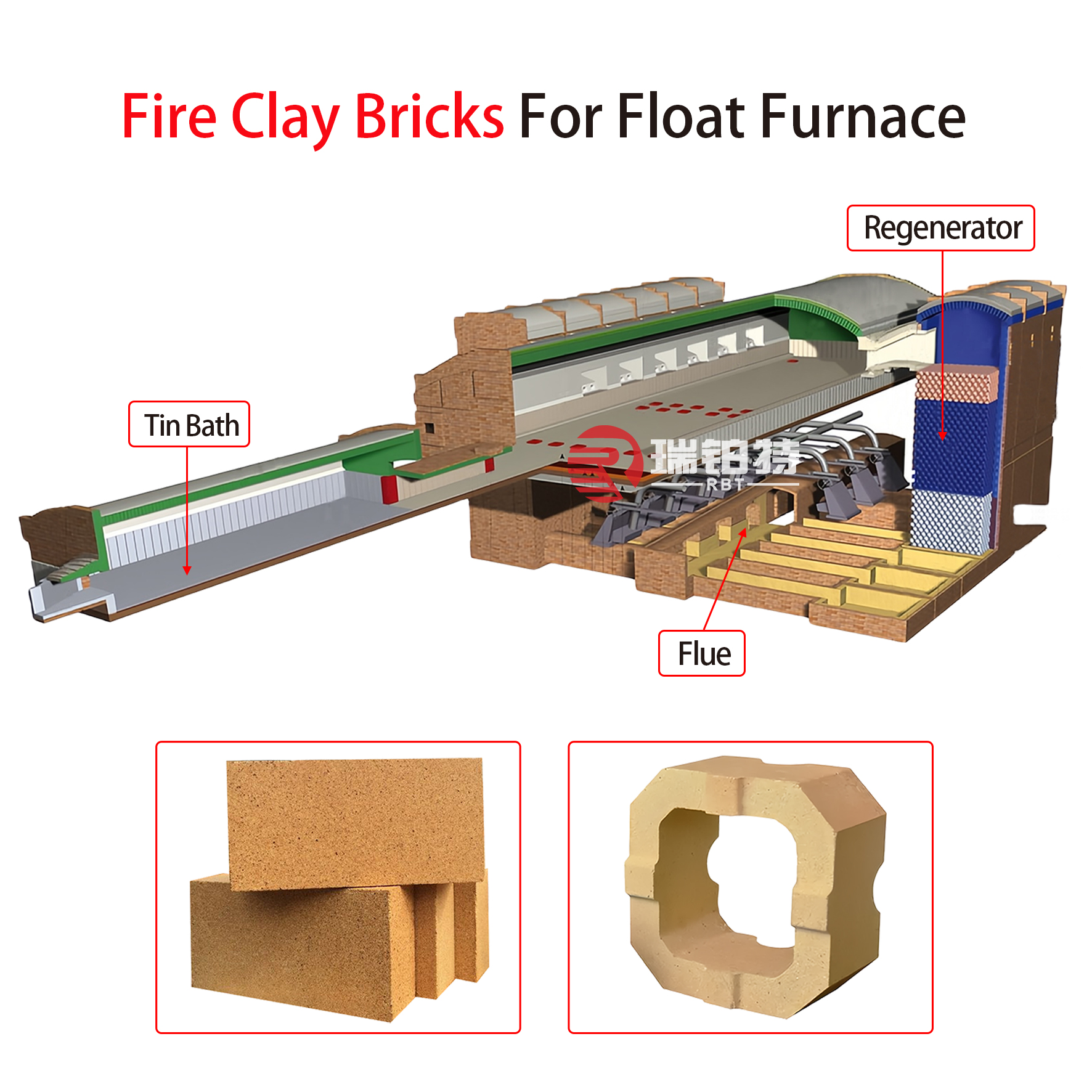

Izitena zodongwe lomlilo kwii-oven zeglasi:

Izithako eziphambili: I-Al2O3 kunye ne-SiO2, umxholo we-Al2O3 uphakathi kwe-30% ~ 45%, i-SiO2 iphakathi kwe-51% ~ 66%. Ubushushu bokusebenza: ubushushu obuphezulu bokusebenza yi-1350 ~ 1500℃. Iimpawu: Yinto enganyangekiyo ene-asidi encinci enokumelana okuhle, uzinzo lobushushu kunye nokuqhuba okuphantsi kobushushu. Isetyenziselwa ikakhulu ukwenza udonga olusezantsi lwedama le-oven, udonga lwedama lendawo yokusebenza kunye nendlela, udonga, i-arch, izitena ezisezantsi kunye nomjelo wegumbi lokugcina ubushushu.

Izitena ze-alumina eziphezulu kwii-oven zeglasi:

Izinto eziphambili: iSiO2 kunye ne-Al2O3, kodwa umxholo we-Al2O3 kufuneka ube ngaphezulu kwe-46%. Ubushushu bokusebenza: Ubushushu obuphezulu bokusebenza yi-1500 ~ 1650℃. Iimpawu: Ukumelana nokugqwala okuhle, kwaye kunokumelana nokugqwala okuvela kwi-asidi kunye ne-alkaline slags. Isetyenziswa kakhulu kwiindawo zokugcina ubushushu, kunye nezixhobo ezichaseneyo zamachibi okusebenza, imijelo yezinto kunye nee-feeders.

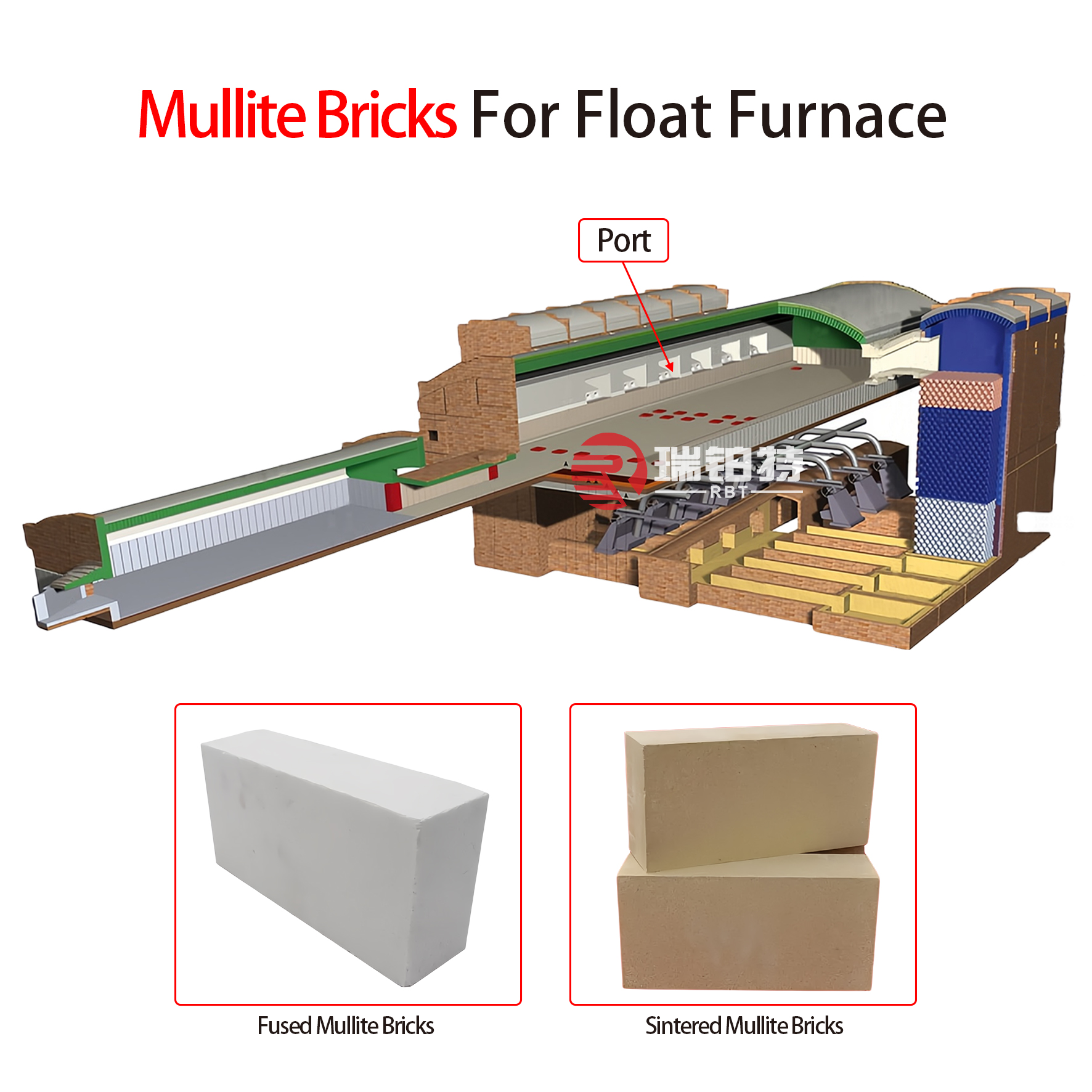

Izitena ezininzi:

Eyona nto iphambili kwizitena ze-mullite yi-Al2O3, kwaye umxholo wayo umalunga ne-75%. Ngenxa yokuba ikakhulu ziikristale ze-mullite, ibizwa ngokuba zizitena ze-mullite. Ubuninzi yi-2.7-3 2g/cm3, i-open porosity yi-1%-12%, kwaye ubushushu obuphezulu bokusebenza yi-1500~1700℃. I-mullite e-Sintered isetyenziselwa kakhulu ukwakhiwa kweendonga zegumbi lokugcina ubushushu. I-mullite edibeneyo isetyenziselwa kakhulu ukwakhiwa kweendonga zedama, imingxunya yokujonga, iintsika zodonga, njl.njl.

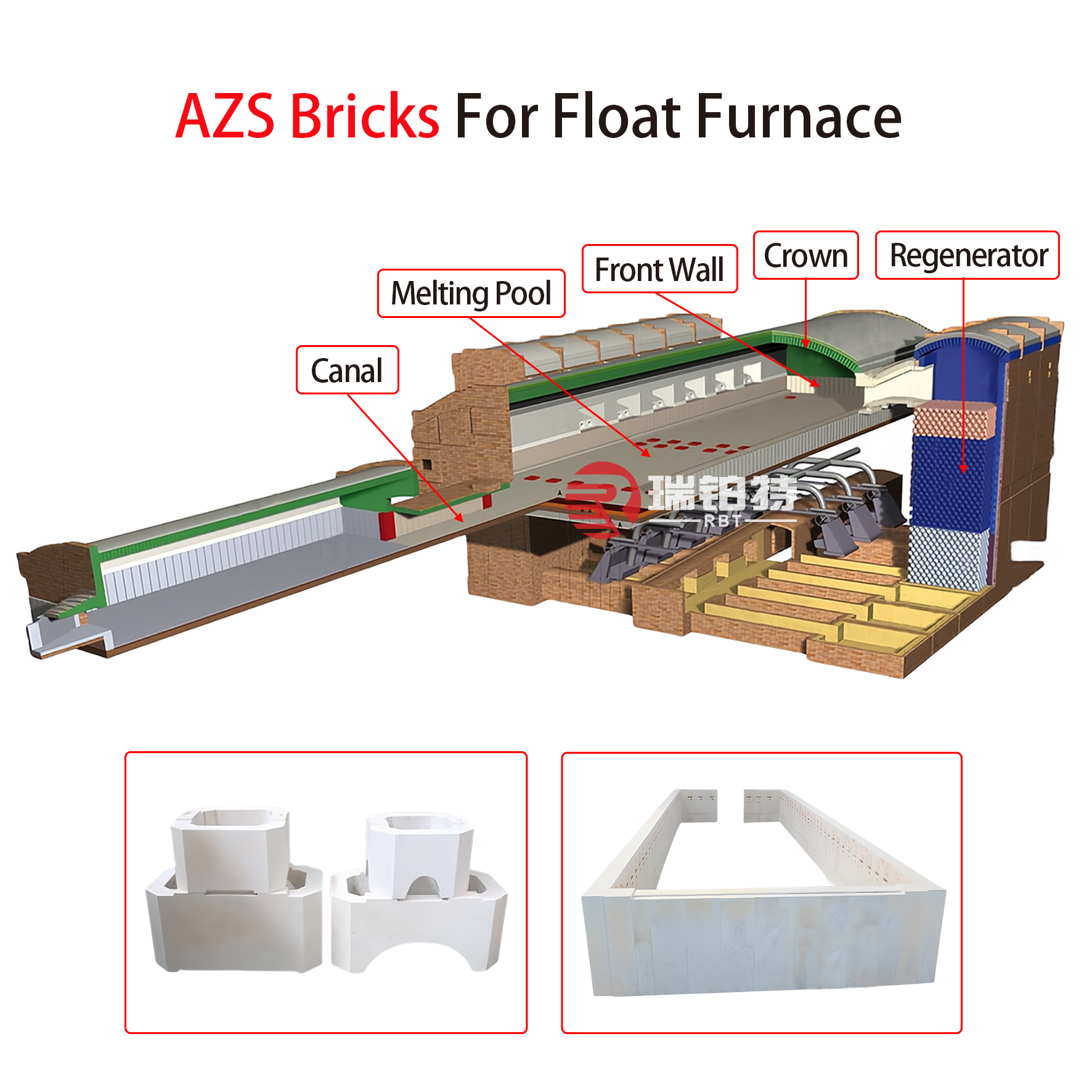

Izitena ze-zirconium corundum ezixutyiweyo:

Izitena ze-zirconium corundum ezixutyiweyo zikwabizwa ngokuba zizitena zentsimbi emhlophe. Ngokubanzi, izitena ze-zirconium corundum ezixutyiweyo zahlulwe zibe ngamanqanaba amathathu ngokomxholo we-zirconium: 33%, 36%, kunye ne-41%. Izitena ze-zirconium corundum ezisetyenziswa kushishino lweglasi ziqulethe i-50% ~ 70% Al2O3 kunye ne-20% ~ 40% ZrO2. Uxinano yi-3.4 ~ 4.0g / cm3, i-porosity ebonakalayo yi-1% ~ 10%, kwaye ubushushu obuphezulu bokusebenza bumalunga ne-1700℃. Izitena ze-zirconium corundum ezixutyiweyo ezine-zirconium engama-33% kunye nama-36% zisetyenziselwa ukwakha iindonga zedama le-oven, iindonga zesifuba ezinesithuba selangatye, imingxunya emincinci yokuqhumisa i-furnace, imingxunya emincinci ye-furnace ethe tyaba, imingxunya emincinci ye-furnace, imingxunya emincinci ye-furnace, imingxunya emincinci ye-furnace, imingxunya yolwimi, njl. Izitena ze-zirconium corundum ezixutyiweyo ezine-zirconium engama-41% zisetyenziselwa ukwakha iikona zodonga lwedama, imingxunya yokuhamba kwamanzi, kunye nezinye iindawo apho ulwelo lweglasi lukhukulisa kwaye ludlakalisa izinto ezichaseneyo ngamandla. Le nto yeyona nto isetyenziswa kakhulu kwishishini leglasi.

Izitena ze-alumina ezidityanisiweyo:

Ibhekisa kakhulu kwizitena ezixutyiweyo ze-α, i-β corundum, kunye ne-β corundum refractory, ezenziwe ikakhulu yi-92% ~ 94% ye-Al2O3 corundum crystal phase, uxinano lwe-2.9 ~ 3.05g / cm3, i-visceral porosity eyi-1% ~ 10%, kunye nobushushu obuphezulu bokusebenza obumalunga ne-1700℃. I-Fused alumina inokumelana okuhle kakhulu nokugqobhoza kweglasi kwaye phantse akukho ngcoliseko kulwelo lweglasi. Isetyenziswa kakhulu eludongeni lwedama lokusebenza, ezantsi kwechibi, kwitshaneli yokuhamba, eludongeni lwedama lokusebenza, ezantsi kwechibi kunye nezinye iindawo zesithando sokunyibilikisa iglasi ezidibana nolwelo lweglasi kwaye azifuni ngcoliseko.

Izitena zeQuartz:

Eyona nto iphambili yiSiO2, equlethe ngaphezulu kwe-99%, enobunzima obuyi-1.9~2g/cm3, ukunganyangeki kwe-1650℃, ubushushu bokusebenza obumalunga ne-1600℃, kunye nokumelana nokukhukuliseka kwe-asidi. Isetyenziselwa ukwakha udonga lwedama ngeglasi ye-acidic boron, izitena zemingxunya ye-flame space thermocouple, njl.njl.

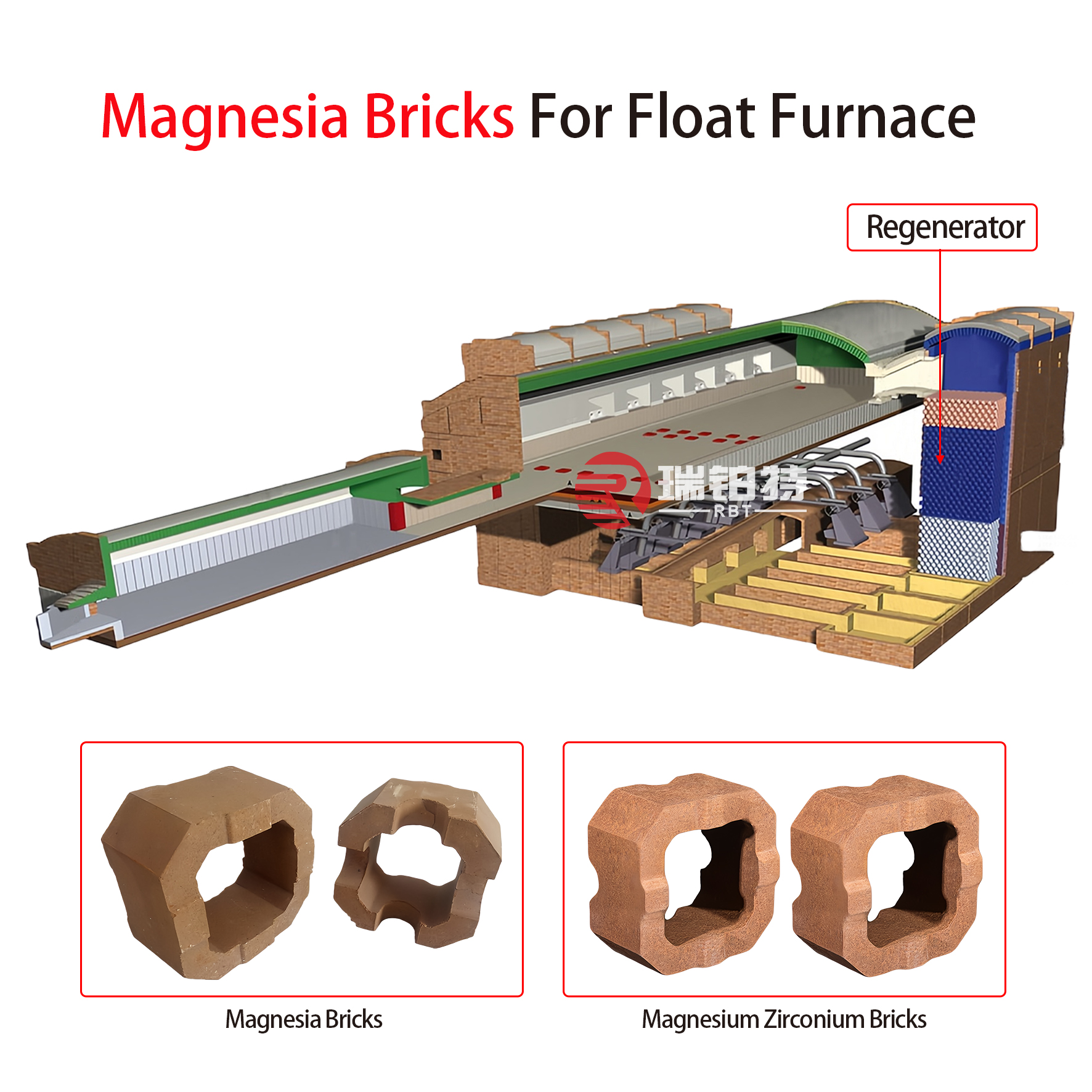

Izinto ezichasayo i-alkaline:

Izinto ezichasene ne-alkaline zibhekisa kakhulu kwizitena ze-magnesia, izitena ze-alumina-magnesia, izitena ze-magnesia-chrome, kunye nezitena ze-forsterite. Ukusebenza kwayo kukumelana nokukhukuliseka kwezinto ze-alkaline, kwaye ukuxhathisa kwayo yi-1900 ~ 2000℃. Isetyenziswa kakhulu eludongeni oluphezulu lwe-regenerator yesithando sokunyibilikisa iglasi, i-arch ye-regenerator, umzimba wegridi, kunye nesakhiwo senxalenye yesithando somlilo esincinci.

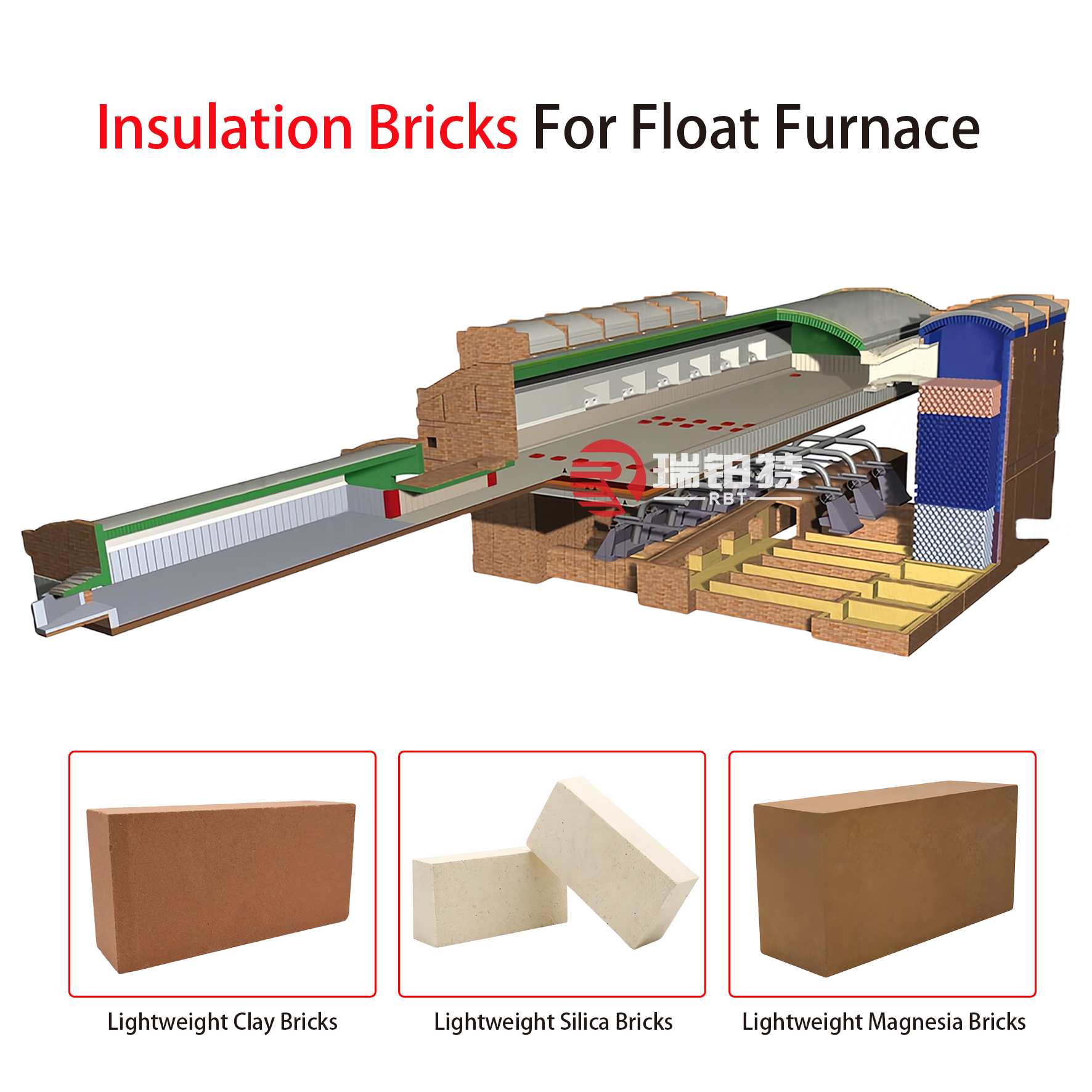

Izitena zokuvala ubushushu kwiifurni zeglasi:

Indawo yokucoca ubushushu yesithando sokunyibilikisa iglasi inkulu kwaye ukusebenza kakuhle kobushushu kuphantsi. Ukuze kongiwe amandla kwaye kuncitshiswe ukusetyenziswa, kufuneka inani elikhulu lezinto zokukhusela ubushushu ukuze kugqunywe ngokupheleleyo. Ngokukodwa, udonga lwedama, umzantsi wedama, i-arch, kunye nodonga olukwi-regenerator, inxalenye yokunyibilikisa, inxalenye yokusebenza, njl. kufuneka zigqunywe ukuze kuncitshiswe ubushushu. Ubude be-porosity yesitena sokukhusela ubushushu bukhulu kakhulu, ubunzima bulula kakhulu, kwaye ubuninzi abudluli kwi-1.3g/cm3. Ekubeni ukusebenza kokudlulisa ubushushu komoya kuphantsi kakhulu, isitena sokukhusela ubushushu esine-porosity enkulu sinesiphumo sokukhusela ubushushu. I-coefficient yayo yokuqhuba ubushushu iphantsi ngokuphindwe ka-2 ~ 3 kuneyezinto ezichaseneyo ngokubanzi, ngoko ke okukhona i-porosity inkulu, kokukhona isiphumo sokukhusela singcono. Kukho iintlobo ezininzi ezahlukeneyo zezitena zokukhusela ubushushu, kubandakanya izitena zokukhusela udongwe, izitena zokukhusela i-silica, izitena zokukhusela i-alumina ephezulu njalo njalo.

Ixesha leposi: Epreli-25-2025