Intshayelelo

Kwimizi-mveliso eshushu kakhulu—ukusuka ekwenzeni intsimbi ukuya kwimveliso yeglasi—izinto ezirhabaxa zingumqolo wemisebenzi ekhuselekileyo nesebenzayo. Phakathi kwezi,izitena ze-mulliteZibalasele ngokuqina kwazo okumangalisayo kobushushu, ukumelana nokugqwala, kunye namandla oomatshini. Ukuqonda ukuhlelwa kwazo kunye nokusetyenziswa kwazo kubalulekile kumashishini afuna ukuphucula ubomi bezixhobo kunye nokunciphisa iindleko zokusebenza. Eli nqaku lichaza iintlobo eziphambili zezitena ze-mullite kunye nokusetyenziswa kwazo kwihlabathi lokwenyani, likunceda wenze izigqibo ezinolwazi malunga neemfuno zakho zoshishino.

Uhlu lweeMullite Bricks

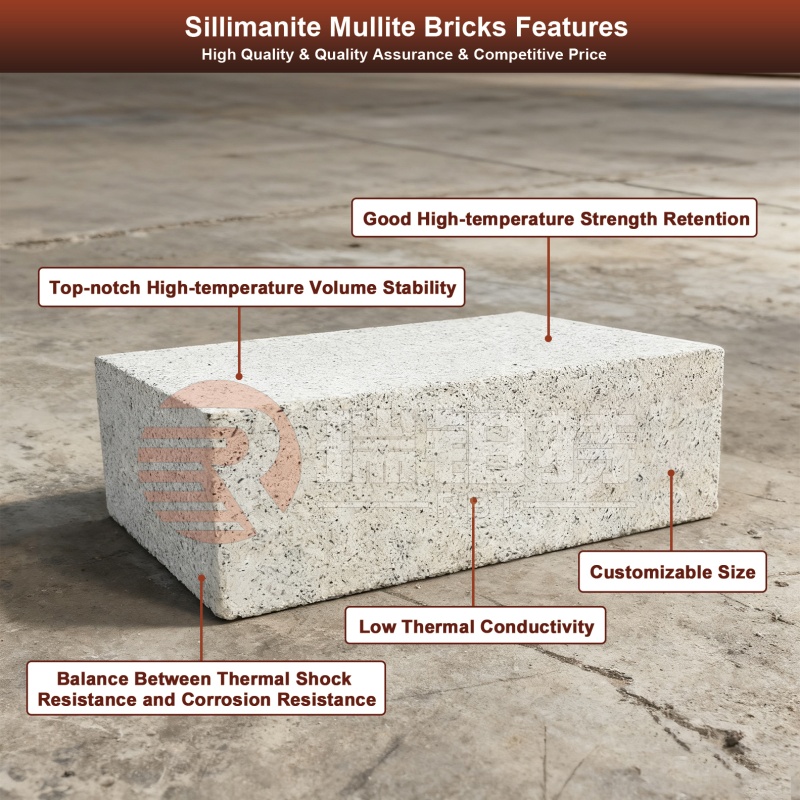

Izitena zeMullite zihlulwe ngokweenkqubo zokuvelisa kunye nezinto ezongeziweyo, nganye ilungiselelwe iimfuno ezithile zoshishino.

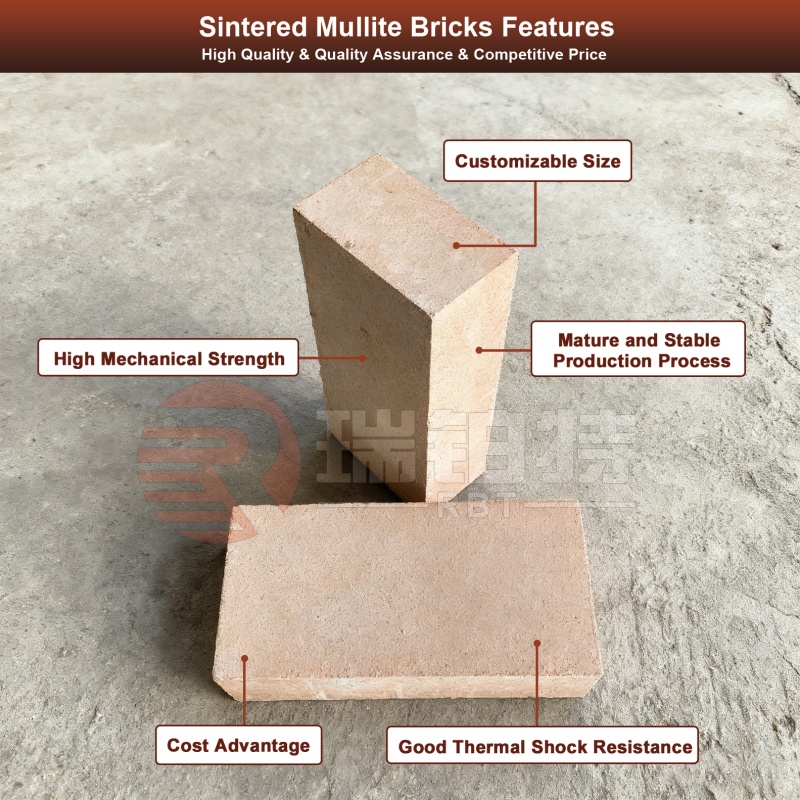

1. Izitena ze-Sintered Mullite

Zenziwe ngokuxuba i-alumina kunye ne-silica ecocekileyo kakhulu, zibumba umxube, kwaye ziwutshise kumaqondo obushushu angaphezu kwe-1600°C, izitena ze-mullite ezitshisiweyo zinesakhiwo esixineneyo kunye ne-porosity ephantsi (ngesiqhelo ingaphantsi kwe-15%). Ezi mpawu zizenza zikwazi ukumelana nokuguguleka kakuhle kunye nokumelana nokutshayiswa kobushushu—zilungele iindawo ezinokuguquguquka rhoqo kobushushu. Ukusetyenziswa okuqhelekileyo kubandakanya ii-linings zee-ceramic kilns, ii-blast furnace hot blast stoves, kunye namagumbi okutshisa ebhoyila.

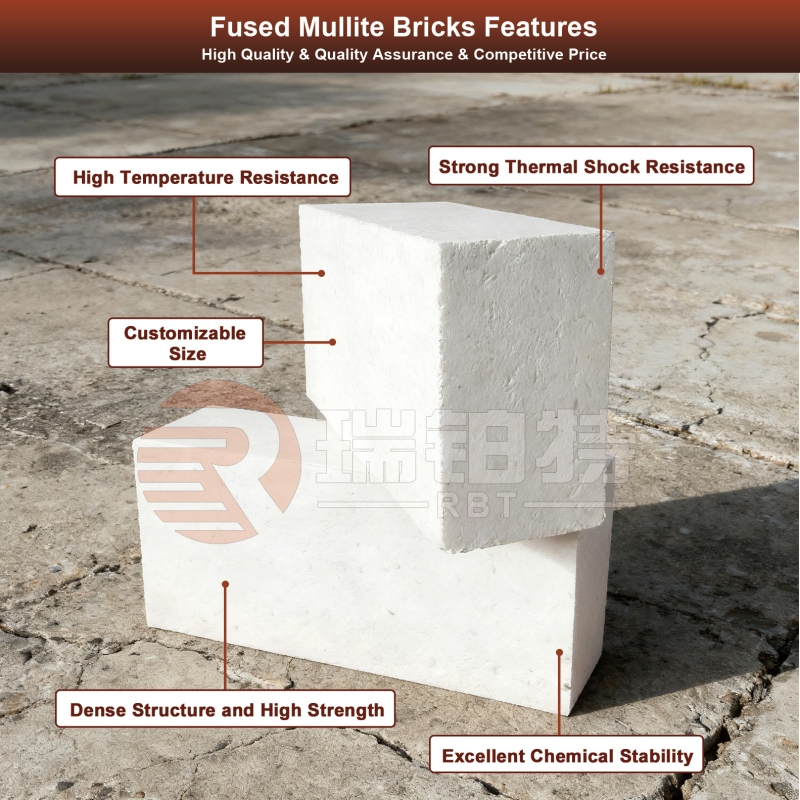

2. Izitena zeMullite ezidityanisiweyo

Ziveliswa ngokunyibilikisa izinto ezikrwada (i-alumina, i-silica) kwisithando sombane (ngaphezulu kwe-2000°C) kunye nokuphosa umxube onyibilikisiweyo kwiimolds, izitena ze-mullite ezixutyiweyo zinezinga eliphantsi kakhulu lokungcola kunye nobumsulwa obuphezulu bekristale. Ukumelana kwazo okuphezulu nokukhukuliseka kweekhemikhali (umz., kwiglasi enyibilikisiweyo okanye kwi-slags) kuzenza zibe lolona khetho luphezulu lwezixhobo zokuvuselela izithando zeglasi, iibhafu zeglasi ezidadayo, kunye nezinye izixhobo ezivezwe kwimidiya enyibilikisiweyo enamandla.

3. Izitena zeMullite ezikhaphukhaphu

Zenziwe ngokongeza ii-agents ezenza iimbobo (umz., uthuli lwesarha, i-graphite) ngexesha lokuveliswa, izitena ze-mullite ezilula zine-porosity ye-40-60% kunye noxinano oluphantsi kakhulu kuneentlobo ze-sintered okanye ze-fused-cast. Inzuzo yazo ephambili kukuqhuba ubushushu obuphantsi (0.4-1.2 W/(m·K)), okunciphisa ukulahleka kobushushu. Zisetyenziswa kakhulu njengeeleya zokukhusela kwii-kilns, kwii-ovens, nakwizixhobo zonyango lobushushu, apho ubunzima kunye nokusebenza kakuhle kwamandla kuyizinto eziphambili.

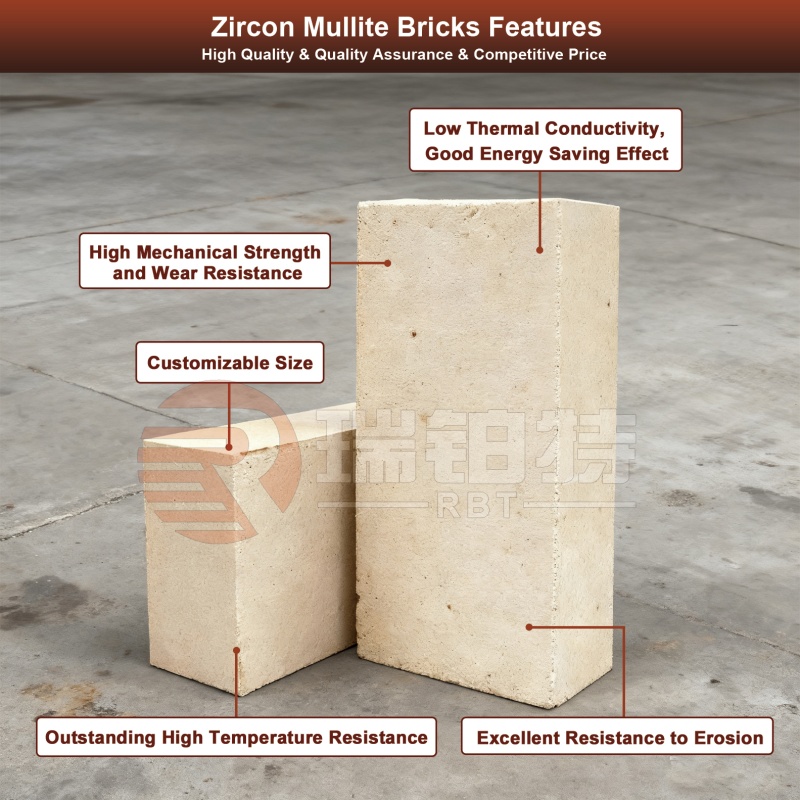

4. Izitena zeZircon Mullite

Ngokufaka i-zircon (ZrSiO₄) kumxube wezinto eziluhlaza, izitena ze-zircon mullite zifumana ukusebenza okuphezulu kobushushu obuphezulu—zinokumelana nobushushu obufikelela kwi-1750°C kwaye zixhathise ukukhukuliseka okuvela kwi-asidi slags. Oku kuzenza zilungele iindawo ezinzima ezifana nezitofu zokunyibilikisa isinyithi ezingenayo i-ferrous (umz., iiseli zokunciphisa i-aluminium) kunye neendawo zokutshisa i-oven ejikelezayo yesamente.

Ukusetyenziswa kwezitena zeMullite

Ukuguquguquka kwezitena ezininzi kuzenza zibe yimfuneko kakhulu kumashishini amaninzi asebenzisa amaqondo obushushu aphezulu.

1. Ushishino lweNsimbi

Imveliso yentsimbi ibandakanya amaqondo obushushu agqithisileyo (ukuya kuthi ga kwi-1800°C) kunye ne-slag erhabaxa. Izitena ze-mullite ezifakwe kwi-sintered zijikeleza izitovu ezishushu, apho ukumelana kwazo nobushushu obuphezulu kuthintela ukuqhekeka ekufudumaleni/ekupholeni ngokukhawuleza. Iindidi ezifakwe kwi-fused-cast zikhusela iiladle kunye nee-tundishes, zinciphisa ukukhukuliseka kwe-slag kwaye zandisa ubomi bezixhobo ngama-20–30% xa kuthelekiswa nezinto zemveli zokunganyangeki.

2. Ishishini leSamente

Ii-oven ezijikeleziswa yisamente zisebenza kwi-1450–1600°C, apho i-alkaline slags ibangela umngcipheko omkhulu wokukhukuliseka. Izitena ze-zircon mullite zijikeleza indawo etshayo ye-oven, zimelana nokuhlaselwa yi-alkali kwaye zigcina ukuqina kwesakhiwo. Izitena ze-mullite ezilula zikwasebenza njengeeleya zokuthintela ukugquma, zinciphisa ukusetyenziswa kwamandla nge-10–15%.

3. Ishishini leeglasi

Iglasi enyibilikisiweyo (1500–1600°C) irhabaxa kakhulu, nto leyo eyenza izitena ze-mullite ezidityanisiweyo zibe yimfuneko kwizixhobo zokuhlaziya izitofu zeglasi kunye nee-linings zeetanki. Zithintela ungcoliseko lweglasi kwaye zandisa ixesha lokusebenza kwesitofu ukuya kwiminyaka emi-5–8, ukusuka kwiminyaka emi-3–5 ngezinye izinto.

4. Amanye Amashishini

Kwizinto zokunyibilikisa isinyithi ezingenayo i-ferrous (i-aluminium, i-copper), izitena ze-zircon mullite ziyamelana nokuguguleka kwesinyithi esinyibilikisiweyo kunye ne-slag. Kwiikhemikhali zepetrochemicals, izitena ze-mullite ezitshisiweyo zijikeleza izitofu eziqhekekayo ngenxa yokuzinza kwazo kubushushu. Kwiiseramikhi, izitena ze-mullite ezilula zigquma ii-kilns, zinciphisa ukusetyenziswa kwamandla.

Isiphelo

Iintlobo ezahlukeneyo zezitena ze-Mullite—ezifakwe i-sintered, ezifakwe i-fused, ezikhaphukhaphu, kunye ne-zircon—zihlangabezana neemfuno ezikhethekileyo zamashishini ashushu kakhulu. Ukusuka ekuphuculeni ukusebenza kakuhle kwesitovu sentsimbi ukuya ekwandiseni ubomi besitovu seglasi, zibonelela ngeenzuzo ezibonakalayo: ixesha elide lokusetyenziswa kwezixhobo, iindleko zamandla eziphantsi, kunye nexesha elincitshisiweyo lokungasebenzi. Njengoko amashishini elandela imveliso ephezulu kunye nokuzinza, izitena ze-mullite ziya kuhlala zisisombululo esiphambili. Khetha uhlobo olufanelekileyo lwesicelo sakho, kwaye uvule amandla azo apheleleyo.

Ixesha leposi: Oktobha-31-2025