Kwimisebenzi yemizi-mveliso apho izixhobo zijongene nokugruzuka okungapheliyo, ukugruzuka, kunye nempembelelo, ukufumana izisombululo zokukhusela ezinokuthenjwa kubalulekile ekunciphiseni ixesha lokungasebenzi kunye nokwandisa imveliso. Iithayile ze-Alumina Ceramic Mosaic zivela njengotshintsho olukhulu, zidibanisa isayensi yezinto eziphucukileyo kunye noyilo lwemodyuli ukuze zinike ukuqina okungenakuthelekiswa nanto kunye nokuguquguquka. Zenzelwe iimeko ezinzima, ezi thayile ziphinda zichaze ukhuseleko lwezixhobo kumashishini aphambili kwihlabathi liphela.

Ubuchule beModular: Amandla oYilo lukaMosaic

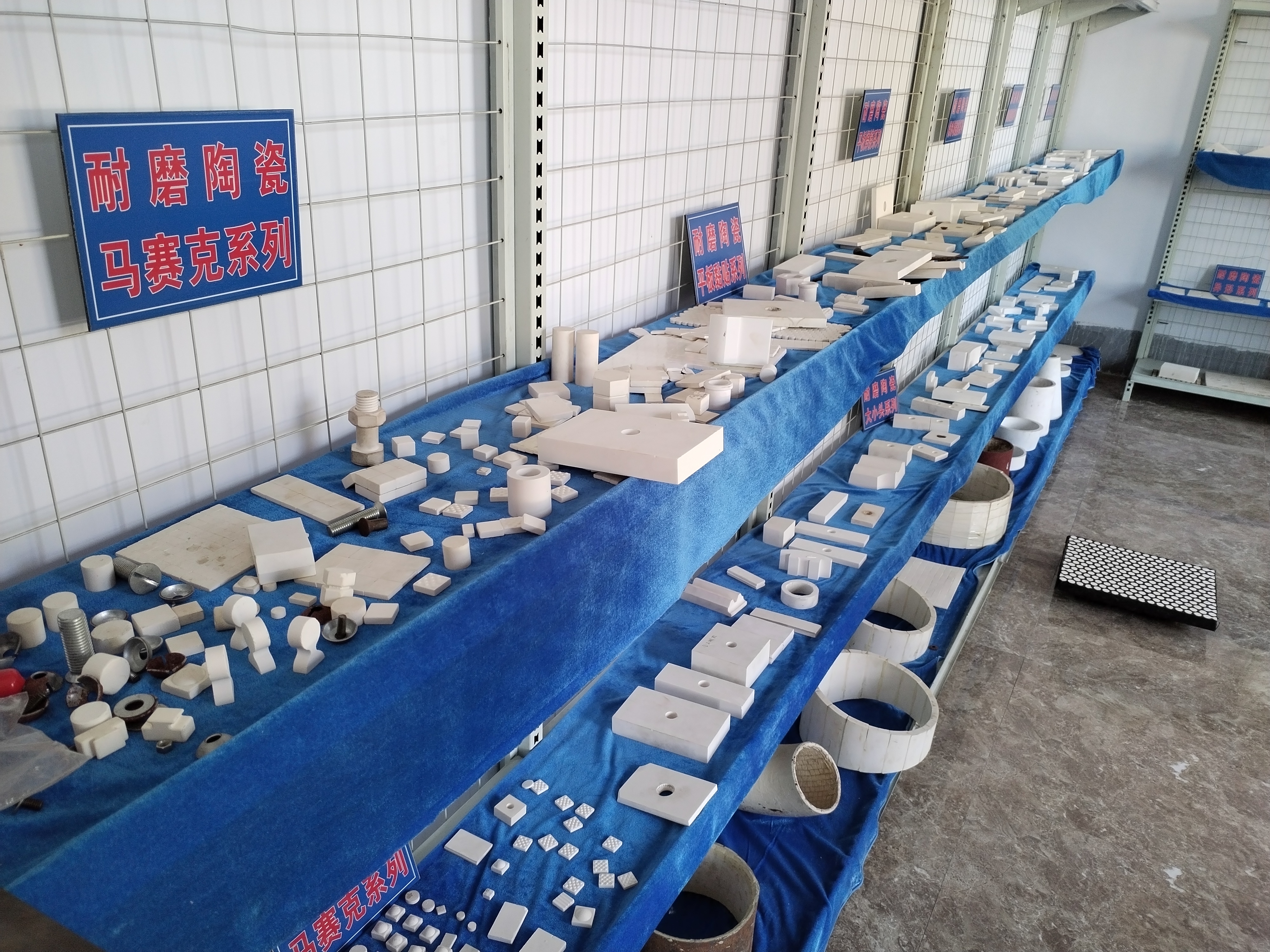

Isiseko seetayile ze-alumina ceramic mosaic sikwisakhiwo sazo esitsha se-modular. Zenziwe njengeetayile ezincinci, ezenziwe ngobuchule (ngesiqhelo ziyi-10mm–50mm ngobukhulu), zibonelela ngokuguquguquka okungenakuthelekiswa nanto ekufakweni. Ngokungafaniyo nee-liners ezinkulu eziqinileyo, ezi thayile ze-mosaic zinokwenziwa ngokwezifiso ukuze zilingane nayo nayiphi na imilo yezixhobo—ukusuka kwiipayipi ezigobileyo kunye nee-hoppers ezikhonkrithi ukuya kwii-chutes ezimile ngendlela engaqhelekanga kunye neendonga zangaphakathi ze-mill. Ithayile nganye yenziwe ngokunyamezelana okuqinileyo, okuqinisekisa ukubopha okungenamthungo okudala umaleko okhuselayo oqhubekayo, ongenakungena.

Olu hlobo lwemodyuli lwenza kube lula ukugcinwa: ukuba ithayile enye yonakele (into engaqhelekanga), ingatshintshwa nganye nganye ngaphandle kokususa yonke inkqubo ye-liner, nto leyo enciphisa kakhulu ixesha lokungasebenzi kunye neendleko zokulungisa. Nokuba zilungisa izixhobo ezikhoyo okanye zidityaniswa koomatshini abatsha, iithayile ze-alumina ceramic mosaic zilungelelanisa neemfuno zakho ngokuchanekileyo okungenakuthelekiswa nanto.

Ukumelana nokuGqoka okuNgalinganiyo

Iithayile ze-Alumina ceramic mosaic zenziwe nge-alumina ecocekileyo kakhulu (90%–99% Al₂O₃), nto leyo ezinika iipropati ezibalaseleyo zoomatshini. Ngobunzima be-Mohs obuyi-9—okwesibini emva kwedayimani—ziphumelela kakhulu kunezixhobo zemveli ezifana nentsimbi, irabha, okanye ii-polymer liners ekumelaneni nokukrazuka kwamatye, iiminerali, kunye nezinto ezi-granular. Kwimisebenzi yemigodi, umzekelo, ziyamelana nempembelelo engapheliyo ye-ore kwii-crushers kunye nee-conveyors, zigcina ukuthembeka kwazo nasemva kweminyaka emininzi yokusetyenziswa kakhulu.

Ngaphaya kokumelana nokuguguleka, ezi thayile zibalaseleyo kwiindawo ezinobungozi zeekhemikhali. Azinawo amandla kwiiasidi ezininzi, ii-alkalis, kunye nezinyibilikisi, nto leyo eyenza ukuba zilungele izityalo zokucubungula iikhemikhali, apho ulwelo olubolayo kunye neegesi ziya konakalisa izinto ezincinci. Xa zidityaniswe nokukwazi kwazo ukumelana namaqondo obushushu afikelela kwi-1600°C, zilukhetho oluthembekileyo lokusetyenziswa kobushushu obuphezulu njengee-oven ze-metallurgical kunye nee-oven zesamente.

Yenzelwe Amacandelo Aphambili Ezoshishino

Ukuguquguquka kweethayile ze-alumina ceramic mosaic kuzenza zibe luncedo kakhulu kumashishini anengxaki yokuguguleka kwezixhobo. Nantsi indlela eziqhuba ngayo ixabiso kumacandelo abalulekileyo:

Ukwembiwa kwemigodi kunye neeminerali:Khusela ii-crushers, ii-ball mills, kunye nee-chutes zokudlulisa kwi-ore erhabaxa, unciphise imijikelo yokutshintshwa kwezixhobo ngama-3-5 amaxesha.

Ukuveliswa kweSamente: Faka imibhobho yezinto ezikrwada, ii-clinker coolers, kunye nemijelo yokuqokelela uthuli ukuze imelane namandla okukhukuliseka kwamasuntswana esamente, ukuqinisekisa ukuveliswa okungaphazanyiswayo.

Ukucubungula iikhemikhali:Khusela iindonga zereactor, iiblade ze-agitator, kunye neetanki zokugcina izinto kwi-crisis media, ukuthintela ungcoliseko kunye nokwandisa ubomi bempahla.

Ukuveliswa koMbane:Iinkqubo zokuhambisa amalahle ezikhuselayo, imibhobho yokuphatha uthuthu, kunye nezixhobo zebhoyila ekungcolisweni kothuthu oluhamba ngeempukane, nto leyo enciphisa iindleko zokugcinwa kwezityalo zamandla.

Ulawulo lweNkunkuma:Iilayini zokutshisa inkunkuma kunye nezixhobo zokurisayikilisha ukuze zikwazi ukumelana nezinto ezirhabaxa nezishushu kakhulu.

Kungakhathaliseki ukuba isicelo sisebenza njani, ezi thayile zenzelwe ukusombulula imingeni yakho yokuguguleka enzima.

Utyalo-mali oluneendleko ezifanelekileyo ekusebenzeni kakuhle kwexesha elide

Nangona iithayile ze-alumina ceramic mosaic zimela utyalo-mali oluphezulu oluvela kwangaphambili, ukonga kwazo ubomi bonke akunakuphikiswa. Ngokunciphisa ixesha lokungasebenzi kwezixhobo (okunokubiza amawaka emisebenzi yemizi-mveliso ngeyure), ukunciphisa iindawo zokutshintshwa, kunye nokwandisa ixesha lokusetyenziswa koomatshini, zizisa imbuyekezo ekhawulezileyo kutyalo-mali (i-ROI)—ngokuqhelekileyo ngaphakathi kweenyanga ezi-6-12.

Xa kuthelekiswa nee-liner zentsimbi ezifuna ukuwelda nokutshintshwa rhoqo, okanye ii-liner zerabha eziwohloka ngokukhawuleza kumaqondo obushushu aphezulu, iithayile ze-alumina mosaic zibonelela ngokusebenza "okulinganayo nokulibala". Iimfuno zazo zokugcinwa okuphantsi kunye nobomi benkonzo ende (iminyaka emi-5-10 kwizicelo ezininzi) zizenza zibe lukhetho olukrelekrele kumashishini agxile kwimisebenzi ezinzileyo nengabizi kakhulu.

Ukulungele Ukutshintsha Ukhuseleko Lwezixhobo Zakho?

Ukuba imisebenzi yakho ithintelwa kukuguguleka kwezixhobo rhoqo, iindleko eziphezulu zokulungisa, okanye ixesha lokungasebenzi elingacwangciswanga, iithayile ze-alumina ceramic mosaic zezona zisombululo uzifunayo. Uyilo lwazo lwemodyuli, ukuqina kwemigangatho yemizi-mveliso, kunye nokusebenza kwecandelo elithile kuzenza zibe semgangathweni ophezulu wokukhusela ukuguguleka.

Nxibelelana neqela lethu namhlanje ukuze uxoxe ngeemfuno zakho zesicelo ezizodwa. Siza kubonelela ngeenkcukacha zeethayile ezenzelwe wena, isikhokelo sokufakelwa, kunye nohlalutyo lokusebenza lwasimahla ukubonisa ukuba ungonga malini. Vumela iithayile ze-alumina ceramic mosaic ziguqule izixhobo zakho ekubeni zizinto ezibangela uxanduva zibe zizinto zexesha elide—kuba kwimisebenzi yemizi-mveliso, ukuqina akuyonto inokwenzeka—kuyimfuneko.

Ixesha leposi: Julayi-23-2025