Ukumisela i-5% ukuya kwi-10% (inxalenye yobunzima) i-Al2O3 kwinxalenye ye-matrix ye-blast furnace carbon/graphite bricks (iibhloko zekhabhoni) kuphucula kakhulu ukumelana nokugqwala kwesinyithi esinyibilikisiweyo kwaye kukusetyenziswa kwezitena zekhabhoni ze-aluminium kwiinkqubo zokwenza isinyithi. Okwesibini, izitena zekhabhoni ze-aluminium zikwasetyenziswa kunyango lwangaphambi kwesinyithi esinyibilikisiweyo kunye nemigxobhozo yempompo.

Izitena zekhabhoni ze-aluminium zonyango lwentsimbi enyibilikisiweyo

Izitena ze-aluminium silicon carbide zisetyenziswa kakhulu kwizixhobo zokuthutha intsimbi enyibilikisiweyo njengeetanki zentsimbi enyibilikisiweyo. Nangona kunjalo, xa olu hlobo lwezinto ezinganyangekiyo lusetyenziswa kwiitanki zentsimbi ezinkulu ezinyibilikisiweyo kunye nabaxubi bentsimbi, kwaye ludibana neemeko ezinzima zokufudumeza nokupholisa, ludla ngokuqhekeka, nto leyo ekhokelela ekuqhekekeni kwesakhiwo. Ukongeza, ngenxa yokuba izitena ze-Al2O3-SiC-C ezisetyenziswa kwiitanki zesinyithi ezinkulu ezishushu kunye nabaxubi bentsimbi zihlala zinomxholo wekhabhoni we-15% kunye nokuqhuba kobushushu okuphezulu njenge-17~21W/(m·K) (800℃), kukho ukuncipha kobushushu bentsimbi enyibilikisiweyo kunye nengxaki yokuguqula amaphepha esinyithi eetanki zesinyithi ezinkulu ezinyibilikisiweyo kunye neemoto ezixubayo. Indlela yokumelana kukufezekisa ukuqhuba kobushushu obuphantsi ngokususa i-SiC, icandelo eliqhuba ubushushu kakhulu, ngelixa kunciphisa umxholo wegrafiti kunye nokucoca igrafiti.

Ngophando olusisiseko, kugqitywa kwelokuba:

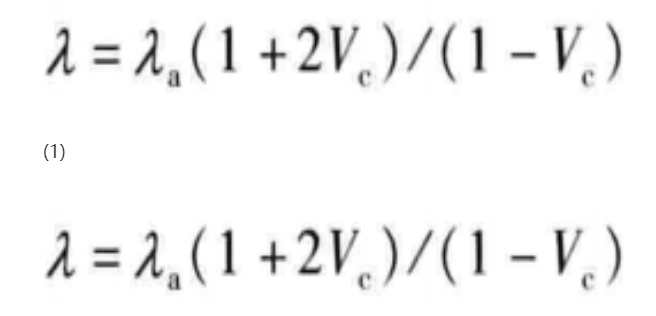

(1) Xa umxholo wegrafiti (inxalenye yobunzima) kwizitena zekhabhoni ze-aluminiyam ungaphantsi kwe-10%, ulwakhiwo lwayo lombutho luqulathe i-Al2O3 eyenza i-matrix eqhubekayo, kwaye ikhabhoni izaliswe kwi-matrix ngohlobo lweengongoma zeenkwenkwezi. Ngeli xesha, i-thermal conductivity λ yesitena sekhabhoni ye-aluminiyam inokulinganiselwa kwifomula (1)

Kwifomyula, i-λa yindlela yokuqhuba ubushushu ye-Al2O3; i-Vc yinxalenye yevolumu ye-graphite. Oku kubonisa ukuba indlela yokuqhuba ubushushu yezitena ze-aluminium carbon ayinanto yakwenza nendlela yokuqhuba ubushushu ye-graphite.

(2) Xa i-graphite icociwe, ukuhanjiswa kobushushu kwesitena se-aluminium carbon akuxhomekekanga kakhulu kwiinxalenye ze-graphite.

(3) Kwizitena ze-aluminium-carbon ezinekhabhoni ephantsi, xa i-graphite icociwe, kunokwenziwa i-dense bonding matrix, enokuphucula ukumelana nokugqwala kwezitena ze-aluminium-carbon.

Oku kubonisa ukuba izitena zekhabhoni ze-aluminium ezisebenzisa ikhabhoni ephantsi zinokukwazi ukuzivumelanisa neemeko zokusebenza kweetanki ezinkulu zesinyithi esishushu kunye neemoto zokuxuba isinyithi kwinkqubo yokwenza isinyithi.

Ixesha leposi: Feb-27-2024