Kwimeko eguqukayo yokuvelisa izinto ezintsha kwezoshishino, ukufumana izixhobo ezifanelekileyo zokuphucula ukusebenza kakuhle, ukunciphisa ukusetyenziswa kwamandla, kunye nokuqinisekisa ukusebenza kwexesha elide kubalulekile. Iimodyuli zefayibha yeseramikhi ziye zavela njengesisombululo esitshintsha umdlalo, ziguqula indlela esijongana ngayo nokufakwa kwe-thermal insulation kunye nokusetyenziswa kwe-refractory.

Zithini iiModules zeCeramic Fiber?

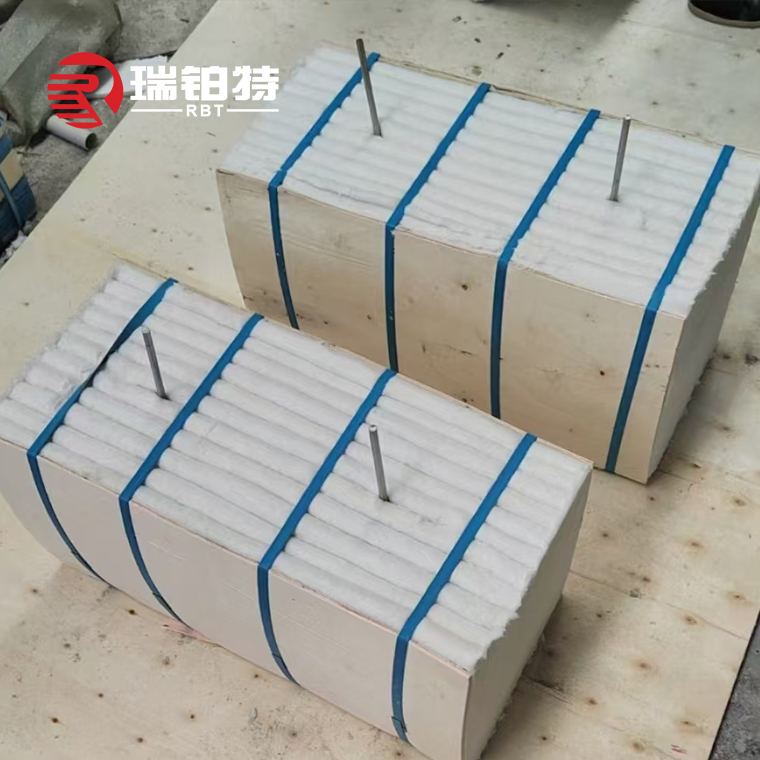

Iimodyuli zefayibha yeseramikhi ziimveliso eziphambili ezichaseneyo ezenziwe ngobuchule kwiingubo zefayibha yeseramikhi ezikumgangatho ophezulu. Ezi ngubo zifakwa kwinkqubo ekhethekileyo yokusonga nokucinezela, kulandele ukufakwa kwee-anchorages ngaphambi kokuba zifakwe. Oku kuphumela kuyilo lwemodyuli olunika ukulula nokusebenza okungenakuthelekiswa nanto. Ngenxa yokukwazi ukufakwa ngokukhawuleza nangokulula kwiintlobo ngeentlobo zee-oven zoshishino kunye nezixhobo zokufudumeza, iimodyuli zefayibha yeseramikhi ziguqula ukwakhiwa nokusebenza kwee-oven zoshishino.

Iingenelo Ezingenakuthelekiswa Nanto

1. Ubushushu obungaqhelekanga

Iimodyuli zefayibha zeseramikhi zenzelwe ukubonelela ngobushushu obugqwesileyo. Ukuqhuba kwazo ubushushu obuphantsi kunciphisa ukudluliselwa kobushushu ngokufanelekileyo, kuqinisekisa ukuba iinkqubo zakho zoshishino zisebenza kumaqondo obushushu afanelekileyo. Ngokunciphisa ukulahleka kobushushu, ezi modyuli aziphuculi nje kuphela ukusebenza kakuhle kwamandla kodwa zikwanegalelo ekongeni iindleko ezinkulu ngokuhamba kwexesha. Oku kuzenza zibe lukhetho olufanelekileyo kumashishini apho ulawulo lobushushu oluchanekileyo kunye nokugcinwa kwamandla kubaluleke kakhulu.

2. Ukumelana nobushushu obuphezulu

Njengoko amaqondo obushushu okwahlulahlula aqala kwi-1050℃ ukuya kwi-1600℃, iimodyuli zefayibha yeseramikhi zinokumelana okumangalisayo namaqondo obushushu aphezulu. Zinokumelana nobushushu obugqithisileyo ngaphandle kokuphazamisa ulwakhiwo lwazo okanye iimpawu zokukhusela. Oku kuzenza zifaneleke ukusetyenziswa kwezinye zezona ndawo zinzima kakhulu kwimizi-mveliso, njengalezo zifumaneka kwicandelo lesinyithi, iglasi, kunye neseramikhi. Nokuba sisithando somlilo esishushu kakhulu okanye i-oven esebenza kumanqanaba obushushu aqatha, iimodyuli zefayibha yeseramikhi zibonelela ngokusebenza okuthembekileyo kunye nokuqina.

3. Ufakelo oluKhawulezayo noLula

Uyilo lweemodyuli zeemodyuli zefayibha yeseramikhi lutshintsha umdlalo xa kufikwa ekufakweni. Ngenxa yesakhiwo sazo esihlanganisiweyo, zinokuhlanganiswa ngqo kwindawo, nto leyo esusa isidingo somsebenzi wokwakha wendabuko onzima nothatha ixesha. Oku kunciphisa kakhulu ixesha lokufaka, kunciphisa ixesha lokungasebenzi kwemisebenzi yakho yemizi-mveliso. Enyanisweni, xa kuthelekiswa neendlela zemveli zokufakela ezingafunekiyo, iimodyuli zefayibha yeseramikhi zinokunyusa ukusebenza kakuhle kokufaka ngaphezulu kwe-50%, okukuvumela ukuba izixhobo zakho zisebenze ngokukhawuleza.

4. Ukusebenza kakuhle kokutywina

Ulwakhiwo olukhethekileyo lokugoba lweemodyuli zefayibha zeseramikhi lubangela ukuba zilingane kakuhle kwaye zingabi namthungo xa zifakelwe. Oku akunciphisi nje kuphela ukubopha ubushushu kodwa kukwathintela ukuvuza komoya, kuphucula ukusebenza kobushushu ngokubanzi kwe-furniture lining. Ukutywinwa okuphuculweyo kukwanegalelo ekusebenzeni kakuhle kwamandla kunye nendawo yokusebenza ezinzileyo, kuqinisekisa ukuba iinkqubo zakho zoshishino zihamba kakuhle kwaye zisebenza kakuhle.

5. Iinketho zokwenza ngokwezifiso

Siyaqonda ukuba zonke izicelo zoshishino zahlukile, yiyo loo nto iimodyuli zethu zefayibha yeseramikhi zibonelela ngokwenziwa ngokwezifiso okuphezulu. Ungakhetha kwiindidi ezahlukeneyo zobukhulu, ubuninzi, kunye neendlela zokubambelela ukuhlangabezana neemfuno ezithile zeprojekthi yakho. Nokuba ufuna imodyuli yesithando somlilo esincinci okanye isithando somlilo esikhulu, singakubonelela ngesisombululo esilungiselelwe wena esifanelana neemfuno zakho ngokugqibeleleyo.

6. Ukuqina Kwexesha Elide

Iimodyuli zefayibha zeseramikhi zenzelwe ukumelana novavanyo lwexesha elide. Ukuxhathisa kwazo uxinzelelo loomatshini, ukutshayiswa kobushushu, kunye nokugqwala kweekhemikhali kuqinisekisa ubomi benkonzo ende. Oku kuthetha ukuba azitshintshwa rhoqo kwaye azigcinwa rhoqo, nto leyo enciphisa iindleko zakho zokusebenza. Ukongeza, ukukwazi kwazo ukugcina iipropati zazo zokukhusela ixesha elide lokusetyenziswa kuzenza zibe lukhetho oluthembekileyo kwizicelo zoshishino zexesha elide.

Izicelo Ezininzi

Ukuguquguquka kweemodyuli zefayibha zeseramikhi kuzenza zilungele uluhlu olubanzi lwezicelo zoshishino:

Ishishini lePetrochemical:Zisetyenziswa kakhulu kwiilinings ze-oven ze-petrochemical ukubonelela nge-thermal insulation esebenzayo, ukuqinisekisa ukusebenza okukhuselekileyo nokugudileyo kweenkqubo ze-petrochemical.

Ushishino lweMetallurgical:Kwicandelo le-metallurgical, iimodyuli zefayibha zeseramikhi zidlala indima ebalulekileyo kwii-oven zonyango lobushushu, zinceda ekufezekiseni ulawulo oluchanekileyo lobushushu bokucubungula isinyithi esisemgangathweni ophezulu.

Ushishino lweeCeramics kunye neGlasi:Kwii-ovens kunye nee-ovens kwimizi-mveliso ye-ceramics kunye neglasi, ezi modyuli zibonelela ngokugcina ubushushu okugqwesileyo, zinegalelo ekuphuculeni umgangatho wemveliso kunye nokonga amandla.

Ishishini Lonyango Lobushushu:Iimodyuli zefayibha zeseramikhi zezona zikhethwayo kwii-oven zonyango lobushushu, zibonelela ngobushushu obufunekayo kwiinkqubo ezahlukeneyo zonyango lobushushu.

Ezinye iiFurnaces zeMizi-mveliso:Zikwasetyenziswa kakhulu nakwezinye izithando zoshishino, njengalezo ezikwimizi-mveliso yokuvelisa umbane, iimoto, kunye neenqwelo-moya, ukuphucula ukusebenza kakuhle kwamandla kunye nokuphucula ukusebenza kwezixhobo.

Kutheni Ukhetha Iimodyuli Zethu ZeCeramic Fiber?

Ukuqinisekisa umgangatho:Iimodyuli zethu zefayibha yeseramikhi zivavanywa ngokungqongqo ukuqinisekisa ukuba ziyahlangabezana nemigangatho ephezulu yoshishino yokusebenza kunye nokuqina.

Uxhaso lobuchwepheshe:Iqela lethu elinolwazi lihlala likulungele ukubonelela ngeengcebiso zobugcisa kunye nenkxaso, ukusuka ekukhetheni imveliso ukuya ekufakweni nasekugcinweni kwayo.

Amaxabiso akhuphisanayo:Sinikezela ngamaxabiso akhuphisanayo ngaphandle kokubeka emngciphekweni umgangatho, siqinisekisa ukuba ufumana elona xabiso lilungileyo lotyalo-mali lwakho.

Ungaphoswa lithuba lokuphucula ukusebenza kwemisebenzi yakho yemizi-mveliso ngeemodyuli zethu zefayibha zeseramikhi eziphambili. Nxibelelana nathi namhlanje ukuze ufunde okungakumbi malunga neemveliso zethu kunye nendlela ezinokunceda ngayo ishishini lakho. Masikuncede uthabathe iinkqubo zakho zemizi-mveliso uye kwinqanaba elilandelayo!

Ixesha leposi: Juni-27-2025