Kwicandelo lemizi-mveliso elinobushushu obuphezulu, ukusebenza kwezinto zokubopha i-oven kuchaphazela ngokuthe ngqo ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso. Njengommeli wezinto ezichasayo ezisebenza kakuhle, izitena ze-magnesia-alumina spinel, ezineempawu zazo ezibalaseleyo, ziye zaba lukhetho olufanelekileyo kumashishini afana nentsimbi, iglasi, kunye nesamente ukumelana nokukhukuliseka kobushushu obuphezulu kunye nokwandisa ubomi bezixhobo, zibonelela ngenkxaso ethembekileyo kwimveliso yemizi-mveliso eshushu obuphezulu.

Ukukhokela iShishini ngokusebenza okugqwesileyo

Izitena ze-Magnesia-alumina spinel zenziwe nge-magnesia kunye ne-aluminium oxide ngeenkqubo ezikhethekileyo. Ulwakhiwo lwazo olukhethekileyo lwekristale luzinika iingenelo ezinamandla zokusebenza. Ezi zitena zibonisa ukumelana okubalaseleyo nobushushu obuphezulu, zikwazi ukumelana nobushushu obuphezulu obufikelela kwi-1800°C. Nokuba zikwiindawo ezishushu kakhulu ixesha elide, zigcina iipropati zomzimba nezikhemikhali ezizinzileyo, zithintela ngempumelelo umonakalo kwii-linings ze-oven ezibangelwa bubushushu obuphezulu.

Ukumelana nokutshayiswa bubushushu luphawu oluphawulekayo lwezitena ze-magnesia-alumina spinel. Ngexesha lokufudumeza rhoqo kunye nokupholisa ii-oven, izinto eziqhelekileyo ezirhabaxa zidla ngokuqhekeka kwaye ziqhekeke ngenxa yoxinzelelo lobushushu. Nangona kunjalo, ngenxa yokwanda kwazo okuphantsi kobushushu kunye nokuqina okuhle, izitena ze-magnesia-alumina spinel zinokunciphisa ngempumelelo imiphumo yoxinzelelo lobushushu, zinciphise kakhulu umngcipheko womonakalo wokutshayiswa bubushushu, zandise ubomi benkonzo, kwaye zinciphise ixesha lokungasebenzi kwe-oven ukuze igcinwe.

Izitena ze-Magnesia-alumina spinel nazo zisebenza kakuhle kakhulu ekukhuseleni ukukhukuliseka kweekhemikhali. Zinokumelana okuhle kakhulu ne-alkaline kunye ne-asidi, kunye neegesi ezishushu kakhulu, zithintela ngempumelelo ukungena kwezinto eziyingozi kwaye zikhusela ukhuseleko lwesakhiwo se-oven. Nokuba zikwimeko ye-alkaline eninzi yokunyibilikisa intsimbi okanye kwindawo ye-asidi ephezulu yokuvelisa iglasi, zinokuzalisekisa imisebenzi yazo yokukhusela ngokuzinzileyo.

Izicelo eziNzulu kwiiShishini ezininzi

Kwishishini lentsimbi, izitena ze-magnesia-alumina spinel zisetyenziswa kakhulu kwiindawo eziphambili zee-converters, ii-ladles, kunye nee-tundishes. Ngexesha lokwenza intsimbi ye-converter, zinokumelana nokukhuhla kunye nokuwohloka kwentsimbi enyibilikisiweyo eshushu kakhulu kunye ne-slag, ukuqinisekisa ukuthembeka kwe-converter lining. Xa zisetyenziswa kwii-ladles nakwii-tundishes, zinokunciphisa ngempumelelo impendulo phakathi kwentsimbi enyibilikisiweyo kunye nezinto ze-lining, ziphucule ubunyulu bentsimbi enyibilikisiweyo, kwaye ziphucule umgangatho wentsimbi. Emva kokuba ishishini elikhulu lentsimbi lamkele izitena ze-magnesia-alumina spinel, ubomi benkonzo yee-ladles zalo bunyuke ukusuka kumyinge wama-60 heats ukuya kuma-120 heats, nto leyo enciphisa kakhulu iindleko zemveliso.

Kwishishini lokuvelisa iiglasi, izitena ze-magnesia-alumina spinel zezona zinto zikhethwayo kwiindawo eziphambili zee-oven zeglasi. Kwiindawo ezishushu nezivuselela ii-oven zeglasi, zinokumelana nokukhukuliseka kokunyibilika kweglasi ebushushu obuphezulu kunye nokukhuhla iigesi ezishushu obuphezulu, zigcine uzinzo lwesakhiwo se-oven, zinciphise amaxesha okugcinwa kwe-oven, kwaye ziphucule ukuqhubeka kunye nozinzo lwemveliso yeglasi. Emva kokusebenzisa izitena ze-magnesia-alumina spinel, umjikelo wokulungiswa kwee-oven zeglasi unokwandiswa ngeminyaka emi-2 ukuya kwemi-3, nto leyo ephucula ngempumelelo iingenelo zoqoqosho zamashishini.

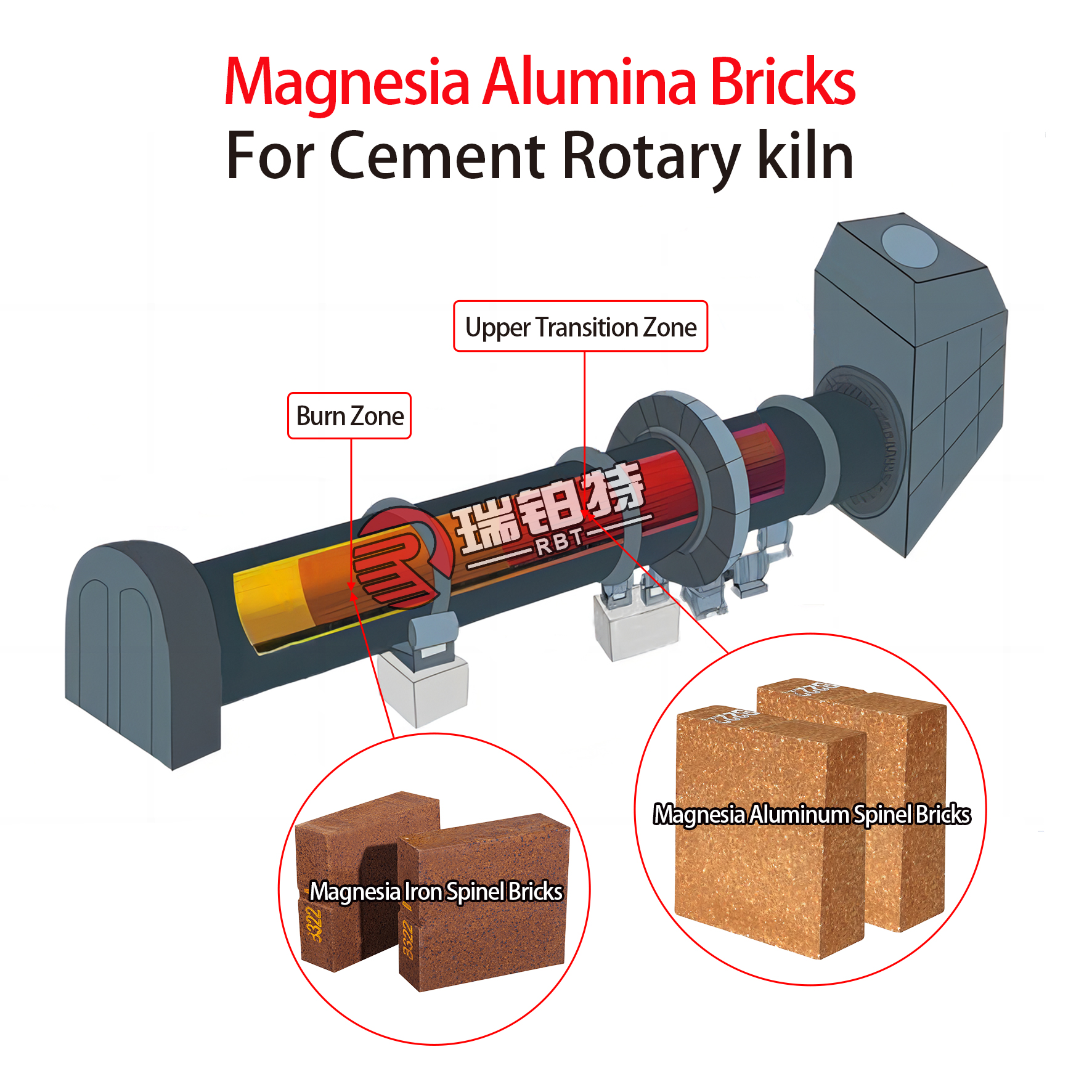

Ngexesha lokuveliswa kwesamente, imeko-bume yobushushu obuphezulu bee-oven ezijikelezayo ibeka iimfuno ezingqongqo kwizinto ezichasene nobushushu obuphezulu. Ngenxa yokumelana kwazo nobushushu obuphezulu, ukumelana nokukrala, kunye nozinzo oluhle lweekhemikhali, izitena ze-magnesia-alumina spinel zidlala indima ebalulekileyo kwindawo yokutshintsha kunye nendawo yokutsha kwee-oven ezijikelezayo, ukuqinisekisa ukusebenza okuzinzileyo komzimba we-oven phantsi kweemeko zobushushu obuphezulu kunye nomthwalo ophezulu kwaye negalelo ekwandiseni imveliso yesamente kunye nomgangatho ophuculweyo.

Isikhokelo soThengo loBugcisa

Xa ukhetha izitena ze-magnesia-alumina spinel, kufuneka kugxininiswe la manqaku alandelayo: Okokuqala, nika ingqalelo kulwakhiwo lweekhemikhali kunye nolwakhiwo lweeminerali zezinto. Izinto eziluhlaza ze-magnesia kunye ne-aluminium oxide ezicocekileyo kakhulu zinokuqinisekisa ukusebenza okuzinzileyo kwezitena. Okwesibini, gxila kwizalathisi zokusebenza ezibonakalayo zeemveliso, ezinje ngobuninzi, ukuxinana okubonakalayo, kunye namandla okutyumza abandayo kubushushu begumbi. Ezi zalathisi zibonisa ngokuthe ngqo umgangatho kunye nokuqina kwezitena. Okwesithathu, vavanya inkqubo yemveliso kunye nenkqubo yokulawula umgangatho yababoneleli. Khetha ababoneleli abanezixhobo zemveliso eziphambili, iinkqubo zokuhlola ezipheleleyo, kunye namava atyebileyo kushishino ukuqinisekisa umgangatho wemveliso othembekileyo. Ukongeza, ngokweemeko ezithile zokusebenza, ukuchaneka kobukhulu kunye nokuguquguquka kwemilo yezitena nazo kufuneka kuqwalaselwe ukuqinisekisa ukwakhiwa kunye nokufakwa okugudileyo.

Ngenxa yokusebenza kwazo okugqwesileyo kunye nokusetyenziswa kwazo okubanzi, izitena ze-magnesia-alumina spinel ziye zaba zizinto ezingafunekiyo nezinokusebenza okuphezulu kwimizi-mveliso eshushu kakhulu. Nokuba kukuphucula ukusebenza kakuhle kwemveliso, ukunciphisa iindleko, okanye ukuqinisekisa umgangatho wemveliso, zinokubonelela ngezisombululo ezithembekileyo kumashishini. Nxibelelana nathi ngoku ukuze ufumane ulwazi lobuchwephesha lwemveliso kunye neenkonzo ezenzelwe wena, kwaye masikhusele imveliso yakho yemizi-mveliso eshushu kakhulu!

Ixesha leposi: Juni-23-2025