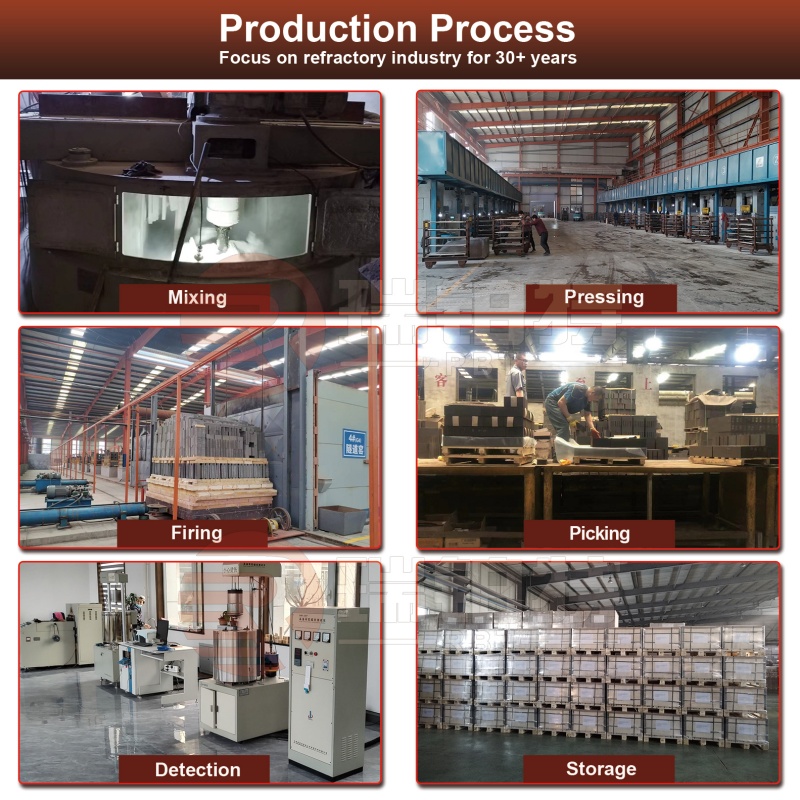

Kwiindawo zee-oven zoshishino ezishushu kakhulu (ezifana nee-converters zokwenza intsimbi, ii-ladles, kunye nee-ovens zokuqhuma),izitena zekhabhoni ze-magnesiumZibonakala njengezinto ezisisiseko zokuchasana nokugqwala, ngenxa yokumelana kwazo kakuhle nokugqwala, ukuzinza kumaqondo obushushu aphezulu, kunye nokumelana nokutshayiswa kubushushu. Inkqubo yokuvelisa ezi zitena yindibaniselwano engqongqo yetekhnoloji kunye nokuchaneka—inyathelo ngalinye limisela ngokuthe ngqo umgangatho wokugqibela wemveliso. Ngezantsi, sikukhokela kwindlela epheleleyo yokwenziwa kwezitena ze-magnesium carbon, sityhila indlela esiqinisekisa ngayo ukuba zonke izitena ziyahlangabezana nemigangatho yezinga loshishino.

1. Ukukhethwa kwezinto eziluhlaza: Isiseko sezitena zekhabhoni zeMagnesium ezikumgangatho ophezulu

Umgangatho wezinto eziluhlaza ngumgca wokuqala wokukhusela ukusebenza kwezitena ze-magnesium carbon. Silandela imigaqo yokukhetha engqongqo ukuqinisekisa ukuba inxalenye nganye ihlangabezana nemigangatho ephezulu:

I-High-Purity Magnesia Aggregate:Sisebenzisa i-fused magnesia okanye i-sintered magnesia enomxholo we-MgO ongaphezulu kwe-96%. Le nto iluhlaza inika isitena ukumelana nobushushu obuphezulu kunye nokumelana nokugqwala, okumelana ngempumelelo nokukhukuliseka kwentsimbi enyibilikisiweyo kunye ne-slag kwii-oven.

Umthombo weCarbon okumgangatho ophezulu:Kukhethwe igrafiti yendalo eneengqayi ezinekhabhoni ezingama-90% nangaphezulu. Ulwakhiwo lwayo oluneeleya luphucula ukumelana nobushushu bezitena, nto leyo enciphisa umngcipheko wokuqhekeka ngenxa yotshintsho olukhawulezileyo lobushushu ngexesha lokusebenza kwesithando somlilo.

Isibopheleli sePremium:I-resin ye-phenolic (eguqulweyo ukuze ikwazi ukumelana nobushushu obuphezulu) isetyenziswa njengesihlanganisi. Iqinisekisa ukubopha okuqinileyo phakathi kwe-magnesia kunye ne-graphite, ngelixa ithintela ukuguquguquka okanye ukubola kumaqondo obushushu aphezulu, okuya kuchaphazela ukuthembeka kwesitena.

Izongezo zokulandelela:Kongezwa inani elincinci lee-antioxidants (ezifana nomgubo we-aluminiyam, umgubo we-silicon) kunye nezixhobo zokusila ukuze kuthintelwe i-graphite oxidation kunye nokuphucula uxinano lwezitena. Zonke izinto ezikrwada zivavanywa kathathu ukuze kususwe ukungcola okunokunciphisa ukusebenza.

2. Ukutyumza nokuGquma: Ulawulo lobungakanani beenxalenye ezichanekileyo zesakhiwo esifanayo

Ukusasazwa kobukhulu beesuntswana ezifanayo kubalulekile ekuqinisekiseni uxinano kunye namandla ezitena zekhabhoni ye-magnesium. Eli nqanaba lilandela iiparameter zobugcisa ezingqongqo:

Inkqubo yokutyumza:Okokuqala, iibhloko ezinkulu ze-magnesia kunye ne-graphite zicolwa zibe ngamasuntswana amancinci kusetyenziswa ii-jaw crushers kunye nee-impact crushers. Isantya sokucola silawulwa kwi-20-30 rpm ukuze kuthintelwe ukugqithisa kakhulu kunye nomonakalo kwisakhiwo sezinto eziluhlaza.

Uvavanyo kunye noHlelo:Izinto ezicoliweyo zihluzwa ngezikrini ezingcangcazelayo ezinamaleya amaninzi (ezinobukhulu be-mesh obuyi-5mm, 2mm, kunye ne-0.074mm) ukuze zahlulwe zibe zii-aggregates ezirhabaxa (3-5mm), ii-aggregates eziphakathi (1-2mm), ii-aggregates ezincinci (0.074-1mm), kunye nee-powders ezithambileyo kakhulu (<0.074mm). Impazamo yobukhulu be-particle ilawulwa ngaphakathi kwe-±0.1mm.

Ukuhlanganiswa kweGranule:Ubungakanani obahlukeneyo bee-particle buxutywa kwi-mixer enesantya esiphezulu imizuzu eli-10-15 ngesantya se-800 rpm. Oku kuqinisekisa ukuba ibhetshi nganye yee-granules inomxube ofanayo, nto leyo ebeka isiseko soxinano lwezitena olufanayo.

3. Ukuxuba nokuxova: Ukufezekisa uBumbano oluqinileyo phakathi kwezinto

Inqanaba lokuxuba nokuxova limisela amandla okubopha phakathi kwezinto eziluhlaza. Sisebenzisa abaxubi abaphambili be-double-helix kwaye silawula ngokungqongqo iimeko zenkqubo:

Ukuxuba Izinto Ezomileyo Ngaphambi Kokuba Zixutywe:Ii-aggregates ezirhabaxa, eziphakathi, nezicolekileyo zixutywa kuqala zome imizuzu emi-5 ukuqinisekisa ukusasazwa ngokulinganayo kwenxalenye nganye. Eli nyathelo lithintela ukuxinana kwekhabhoni okanye i-magnesia kwindawo ethile, okunokubangela umahluko ekusebenzeni.

Ukongeza i-Binder kunye ne-Kneading:I-resin ye-phenolic eguquliweyo (eshushu ukuya kuma-40-50℃ ukuze kube lula ukunyibilika) yongezwa kumxube owomileyo, ilandelwe yimizuzu engama-20-25 yokuxova. Ubushushu bomxube bugcinwa kwi-55-65℃, kwaye uxinzelelo lulawulwa kwi-0.3-0.5 MPa—oku kuqinisekisa ukuba i-binder iyisonga ngokupheleleyo isuntswana ngalinye, yenze isakhiwo esizinzileyo se-"magnesia-graphite-binder".

Uvavanyo lokungaguquguquki:Emva kokuxova, ukuqina komxube kuvavanywa rhoqo emva kwemizuzu eli-10. Ukuqina okufanelekileyo yi-30-40 (kulinganiswa ngemitha yokulinganisa ukuqina eqhelekileyo); ukuba yomile kakhulu okanye imanzi kakhulu, idosi yokubopha okanye ixesha lokuxova lilungiswa ngexesha langempela.

4. Ukwenziwa kwePress: Ukubumba iHigh-Pressure for Density and Strength

Ukwakha i-press forming linyathelo elinika izitena ze-magnesium carbon imo yazo yokugqibela kwaye liqinisekisa uxinano oluphezulu. Sisebenzisa ii-hydraulic presses ezizenzekelayo ezinolawulo oluchanekileyo loxinzelelo:

Ukulungiswa kweMbumba:Iimold zentsimbi ezenzelwe wena (ngokweemfuno zabathengi zobukhulu bezitena, ezinje nge-230×114×65mm okanye ubukhulu obukhethekileyo) ziyacocwa kwaye zigqunywe nge-ejenti yokukhulula umxube ukuze unganamatheli kwimold.

Uxinzelelo oluphezulu:Umxube oxoviweyo ugalelwa kwi-mold, kwaye i-hydraulic press isebenzisa uxinzelelo lwe-30-50 MPa. Isantya sokucinezela simiselwe kwi-5-8 mm/s (ukucinezela kancinci ukususa amaqamza omoya) kwaye sigcinwe imizuzwana emi-3-5. Le nkqubo iqinisekisa ukuba ubuninzi bezitena bufikelela kwi-2.8-3.0 g/cm³, kunye ne-porosity engaphantsi kwe-8%.

Ukudilizwa kunye nokuhlolwa:Emva kokucinezela, izitena ziyasuswa ngokuzenzekelayo kwaye zihlolwe ukuba azinazo iziphene zomphezulu (ezifana nemingxunya, imiphetho engalinganiyo). Izitena ezineziphene ziyaliwa ngoko nangoko ukuze zingangeni kwinkqubo elandelayo.

5. Unyango lobushushu (Ukunyanga): Ukuphucula ukuBopha kunye nozinzo lweBinder

Unyango lobushushu (ukunyanga) luqinisa isiphumo sokubopha kwe-binder kwaye lususa izinto eziguquguqukayo kwizitena. Sisebenzisa ii-tunnel kilns ezinolawulo oluchanekileyo lobushushu:

Ukufudumeza ngeStepwise: Izitena zifakwa kwi-oven yetonela, kwaye ubushushu bunyuswa ngokulandelelana:

20-80℃ (iiyure ezi-2):Vuthela ukufuma komphezulu;

80-150℃ (iiyure ezi-4):Khuthaza ukunyanga i-resin kwangaphambili;

150-200℃ (iiyure ezi-6):Ukudibanisa nokunyanga i-resin ngokupheleleyo;

200-220℃ (iiyure ezi-3):Zinzisa isakhiwo sezitena.

Izinga lokufudumeza lilawulwa kwi-10-15℃/iyure ukuthintela ukuqhekeka ngenxa yoxinzelelo lobushushu.

Ukususwa Kwezinto Eziguquguqukayo:Ngexesha lokunyibilikisa, izinto eziguquguqukayo (ezifana nee-resin ezincinci ze-molecule) zikhutshwa ngenkqubo yokukhupha umoya kwi-oven ye-kiln, ukuqinisekisa ukuba isakhiwo sangaphakathi sesitena sixinene kwaye asinazo iindawo ezingenanto.

Inkqubo Yokupholisa: Emva kokunyibilika, izitena zipholiswa kubushushu begumbi ngesantya se-20℃/iyure. Ukupholisa ngokukhawuleza kuyathintelwa ukuthintela umonakalo wokutshatyalaliswa kobushushu.

6. Ukuhlolwa koMgangatho emva kokwenziwa kwezinto kunye noBuchule: Ukuqinisekisa ukuba zonke izitena ziyahlangabezana nemigangatho

Inqanaba lokugqibela lemveliso ligxile ekucutshungulweni ngokuchanekileyo kunye novavanyo oluqinileyo lomgangatho ukuqinisekisa ukuba isitena ngasinye se-magnesium carbon siyahlangabezana neemfuno zesicelo semizi-mveliso:

Ukusila nokusika:Izitena ezinemiphetho engalinganiyo ziyagaywa kusetyenziswa oomatshini bokugaya be-CNC, ukuqinisekisa ukuba impazamo yobukhulu ingaphakathi kwe-±0.5mm. Izitena ezinemilo ekhethekileyo (ezifana nezitena ezinemilo ye-arc zabaguquli) zicutshungulwa kusetyenziswa amaziko oomatshini be-5-axis ukuze zihambelane negophe lodonga lwangaphakathi lwesithando.

Uvavanyo olupheleleyo loMgangatho:Ibhetshi nganye yezitena idlula kwiimvavanyo ezi-5 ezibalulekileyo:

Uvavanyo lobuninzi kunye ne-Porosity:Usebenzisa indlela ye-Archimedes, qinisekisa ukuba ubuninzi buyi-≥2.8 g/cm³ kunye ne-porosity ≤8%.

Uvavanyo lwamandla oxinzelelo:Vavanya amandla okuxinwa kwesitena (≥25 MPa) usebenzisa umatshini wokuvavanya osetyenziswa kwihlabathi liphela.

Uvavanyo lokuxhathisa ukuShukuma koMlilo:Emva kwemijikelo eli-10 yokufudumeza (1100℃) kunye nokuphola (ubushushu begumbi), jonga ukuba akukho miqhekeko (akukho miqhekeko ibonakalayo evunyelweyo).

Uvavanyo lokuxhathisa ukugqwala:Linganisa iimeko zesithando somlilo ukuze uvavanye ukumelana kwezitena nokukhukuliseka kwe-slag enyibilikisiweyo (izinga lokukhukuliseka ≤0.5mm/h).

Uhlalutyo loBume beeKhemikhali:Sebenzisa i-X-ray fluorescence spectrometry ukuqinisekisa umxholo we-MgO (≥96%) kunye nomxholo wekhabhoni (8-12%).

Ukupakishwa kunye nokugcinwa:Izitena ezifanelekileyo zipakishwa kwiibhokisi ezingangenisi manzi okanye kwiipalethi zokhuni, kunye nefilimu engangenisi manzi ejikelezileyo ukuze kuthintelwe ukufunxwa komswakama ngexesha lokuthuthwa. Iphakheji nganye ibhalwe inombolo yebhetshi, umhla wokuveliswa, kunye nesatifikethi sokuhlolwa komgangatho ukuze kulandeleke.

Kutheni Ukhetha Izitena Zethu Zekhabhoni ZeMagnesium?

Inkqubo yethu engqongqo yemveliso (ukusuka ekukhetheni izinto eziluhlaza ukuya ekucutshungulweni emva kokulungiswa) iqinisekisa ukuba izitena zethu ze-magnesium carbon zisebenza kakuhle kakhulu kwii-oven zoshishino ezinobushushu obuphezulu. Nokuba zezokuguqula intsimbi, iiladle, okanye ezinye izixhobo ezinobushushu obuphezulu, iimveliso zethu zinokwenza oku:

Yimelane namaqondo obushushu afikelela kwi-1800℃ ngaphandle kokuthambisa okanye ukuguquguquka.

Yixhathise intsimbi enyibilikisiweyo kunye nokukhukuliseka kwe-slag, nto leyo eyandisa ubomi benkonzo yesithando nge-30% nangaphezulu.

Nciphisa amaxesha okugcinwa kwempahla kunye neendleko zemveliso kubathengi.

Sinikezela ngezisombululo ezenzelwe wena ngokwehlobo lwesithando sakho, ubungakanani, kunye neemeko zokusebenza. Qhagamshelana nathi namhlanje ukuze ufunde okungakumbi malunga nenkqubo yethu yokuvelisa izitena ze-magnesium carbon okanye ufumane ikowuteshini yasimahla!

Ixesha leposi: Okthobha-29-2025