Iingenelo zezitena ze-magnesia carbon zezi:ukumelana nokukhukuliseka kwe-slag kunye nokumelana okuhle nokutshayiswa kobushushu. Ngaphambili, ingxaki yezitena ze-MgO-Cr2O3 kunye nezitena ze-dolomite yayikukuba zazifunxa izinto ze-slag, nto leyo eyabangela ukuqhekeka kwesakhiwo, nto leyo eyabangela umonakalo wangaphambi kwexesha. Ngokudibanisa i-graphite, izitena ze-magnesia carbon zasusa le ngxaki. Uphawu lwayo kukuba i-slag ingena kuphela kumphezulu wokusebenza, ngoko ke umaleko wokusabela Uvalelwe kumphezulu wokusebenza, isakhiwo asinamaxolo amaninzi kwaye sihlala ixesha elide.

Ngoku, ukongeza kwizitena ze-carbon ze-asphalt kunye ne-resin-bonded magnesia (kuquka izitena ze-magnesia ezifakwe kwi-oyile),Izitena ze-magnesia carbon ezithengiswayo kwimarike ziquka:

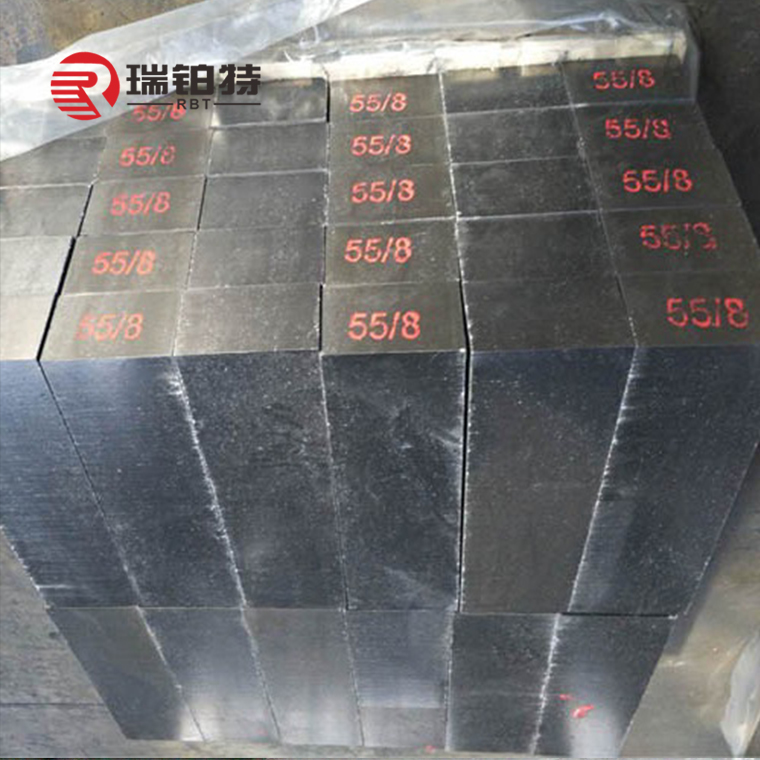

(1) Izitena ze-Magnesia carbon ezenziwe nge-magnesia equlethe i-96% ~ 97% MgO kunye ne-graphite 94% ~ 95% C;

(2) Izitena zekhabhoni zeMagnesia ezenziwe ngeMagnesia equlethe i-97.5% ~ 98.5% MgO kunye neGraphite 96% ~ 97% C;

(3) Izitena ze-Magnesia carbon ezenziwe nge-magnesia equlethe i-98.5% ~ 99% MgO kunye ne-98% ~ C graphite.

Ngokwesiqulatho sekhabhoni, izitena zekhabhoni ze-magnesia zahlulwe zibe:

(I) Izitena ze-magnesia ezifakwe kwi-oyile evuthayo (umxholo wekhabhoni ungaphantsi kwe-2%);

(2) Izitena ze-magnesia ezibotshelelwe kwikhabhoni (umxholo wekhabhoni ungaphantsi kwe-7%);

(3) Izitena zekhabhoni ze-magnesia ezibotshelelweyo ze-synthetic resin (umxholo wekhabhoni yi-8% ~ 20%, ukuya kuthi ga kwi-25% kwiimeko ezimbalwa). Ii-antioxidants zihlala zongezwa kwizitena zekhabhoni ze-magnesia ezibotshelelweyo ze-asphalt / resin (umxholo wekhabhoni yi-8% ukuya kwi-20%).

Izitena zekhabhoni zeMagnesia ziveliswa ngokudibanisa isanti yeMgO ecocekileyo kakhulu kunye negrafiti enamaxolo, umnyama wekhabhoni, njl. Inkqubo yokuvelisa ibandakanya ezi nkqubo zilandelayo: ukutyumza izinto eziluhlaza, ukuhluza, ukuhlela, ukuxuba ngokwendlela yoyilo lwefomula yezinto kunye nokusebenza kokuseta imveliso, ngokwendibaniselwano. Ubushushu bohlobo lwearhente buphakanyiswa bufikelele kwi-100 ~ 200℃, kwaye buxovwa kunye ne-binder ukuze kufunyanwe into ebizwa ngokuba yiMgO-C mud (umxube womzimba oluhlaza). Izinto zodaka zeMgO-C ezisebenzisa i-synthetic resin (ikakhulu i-phenolic resin) zibunjwa kwimeko yokubanda; izinto zodaka zeMgO-C ezidityaniswe ne-asphalt (ezifudunyezwayo ukuya kwimeko yokuba lulwelo) zibunjwa kwimeko yokuba lushushu (malunga ne-100°C). Ngokweemfuno zobungakanani bebhetshi kunye nokusebenza kweemveliso zeMgO-C, izixhobo zokungcangcazela ze-vacuum, izixhobo zokubumba ezicinezelayo, ii-extruders, ii-isostatic presses, ii-hot presses, izixhobo zokufudumeza, kunye nezixhobo zokugquma zingasetyenziselwa ukucubungula izinto zodaka zeMgO-C. kwimo efanelekileyo. Umzimba we-MgO-C owenziweyo ufakwa kwi-oven kwi-700 ~ 1200°C ukuze kulungiswe ubushushu ukuze kuguqulwe i-bonding agent ibe yi-carbon (le nkqubo ibizwa ngokuba yi-carbonization). Ukuze kwandiswe uxinano lwezitena ze-carbon ze-magnesia kwaye kuqiniswe i-bonding, izizalisi ezifana nezibopheleli nazo zingasetyenziselwa ukufunxa izitena.

Kule mihla, i-resin yokwenziwa (ingakumbi i-phenolic resin) isetyenziswa kakhulu njenge-arhente yokubopha izitena ze-magnesia carbon.Ukusetyenziswa kwezitena zekhabhoni ze-magnesia ezibotshelelwe kwi-resin yokwenziwa kunezi nzuzo zilandelayo:

(1) Imiba yokusingqongileyo ivumela ukucutshungulwa nokuveliswa kwezi mveliso;

(2) Inkqubo yokuvelisa iimveliso phantsi kweemeko zokuxuba ezibandayo igcina amandla;

(3) Imveliso ingacutshungulwa phantsi kweemeko ezinganyangekiyo;

(4) Xa kuthelekiswa ne-tar asphalt binder, akukho phase yeplastiki;

(5) Ukwanda komxholo wekhabhoni (igrafiti engaphezulu okanye ilahle le-bituminous) kunokuphucula ukumelana nokuguguleka kunye nokumelana nokulahlwa.

Ixesha leposi: Februwari-23-2024