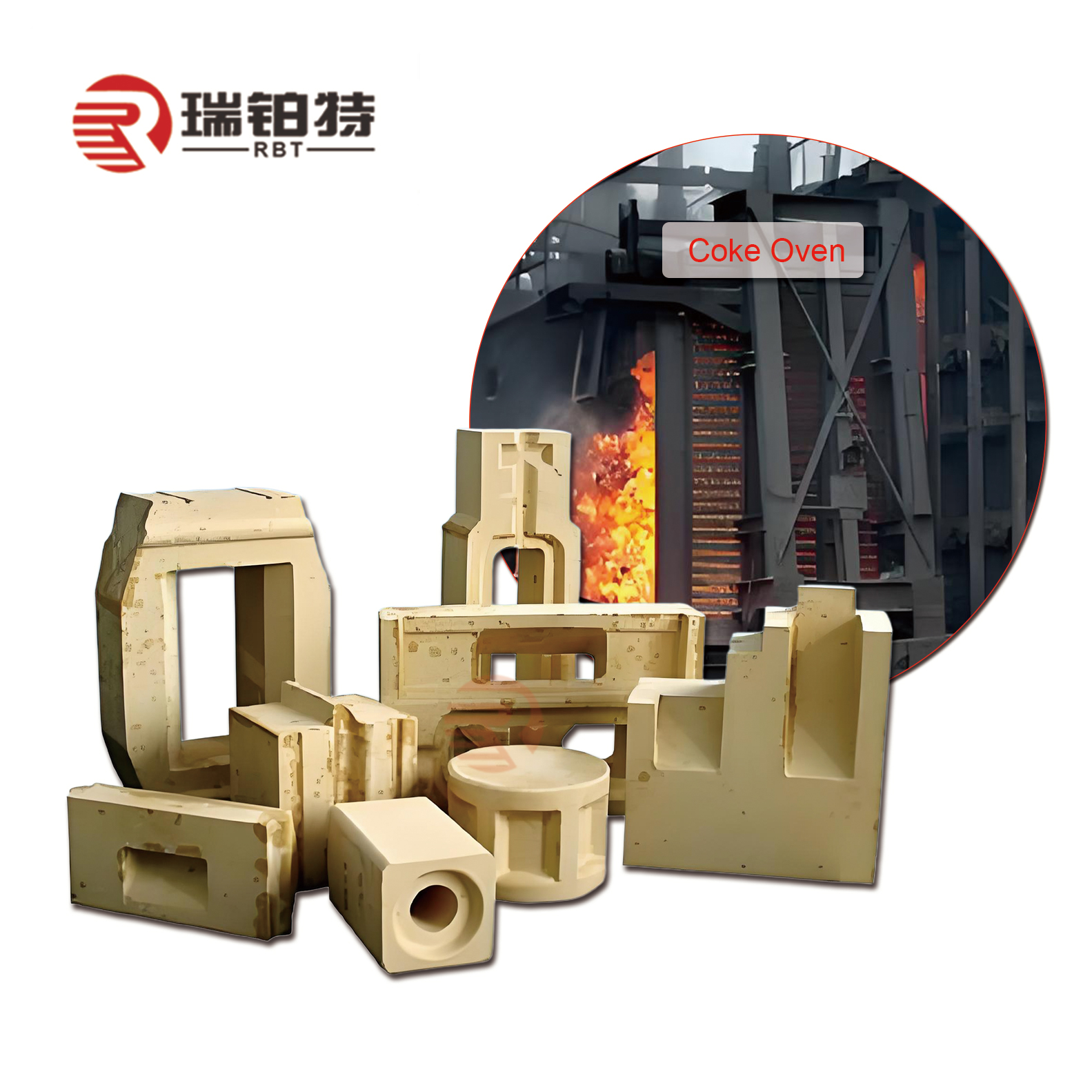

Kukho iintlobo ezininzi zezinto ezichasene ne-refractory ezisetyenziswa kwii-oven ze-coke, kwaye isixhobo ngasinye sineemeko zaso ezithile zokusetyenziswa kunye neemfuno zokusebenza. Ezi zilandelayo zezixhobo ezichasene ne-refractory ezisetyenziswa rhoqo kwii-oven ze-coke kunye neendlela zokuzikhusela:

1. Izinto ezisetyenziswa rhoqo ezichasene ne-coke ovens

Izitena zesilicon

Iimpawu: ukumelana nobushushu obuphezulu (ngaphezulu kwe-1650℃), ukumelana nokugqwala kwe-asidi, kunye nokuzinza okuhle kobushushu.

Ukusetyenziswa: Isetyenziswa kakhulu kwiindawo ezinobushushu obuphezulu ezifana negumbi lokutsha, igumbi lokufaka icarbonization, kunye ne-oven ye-coke.

Ukulumkela:

Izitena zesilicon zinokutshintshatshintsha ikristale ngaphantsi kwama-600℃, nto leyo ebangela utshintsho kumthamo, ngoko ke kufuneka zithintelwe kwiindawo ezinobushushu obuphantsi.

Ngexesha lokwakha, iindawo zokudibanisa izitena kufuneka zilawulwe ngokungqongqo ukuthintela ukwanda kwezitena kwiindawo zokushisa okuphezulu.

Izitena ze-alumina eziphezulu

Iimpawu: ukunganyangeki okuphezulu (ngaphezulu kwe-1750℃), ukumelana kakuhle nokutsha kobushushu, kunye nokumelana okunamandla kokugqwala.

Ukusetyenziswa: Isetyenziswa eludongeni lwesithando somlilo, ezantsi kwesithando somlilo, kwigumbi lokugcina ubushushu nakwezinye iindawo ze-oven ye-coke.

Ukulumkela:

Izitena ezine-alumina eninzi azinawo amandla okuxhathisa ukugqwala kwe-alkaline kwaye kufuneka ziphephe ukudibana ngqo nezinto ze-alkaline.

Ngexesha lokwakha, kufuneka kuqwalaselwe ukomiswa nokubhaka umzimba wezitena ukuze kuthintelwe ukuqhekeka.

Izitena zodongwe lomlilo

Iimpawu: ukumelana nobushushu okuhle, ixabiso eliphantsi, ukumelana kakuhle nokutshiswa kobushushu.

Ukusetyenziswa: kusetyenziswa kwiindawo ezinobushushu obuphantsi ezifana nombhobho we-oven ye-coke kunye nenxalenye esezantsi yegumbi lokugcina ubushushu.

Amanqaku:

Ukungaguquguquki kwezitena zodongwe kuphantsi kwaye akufanelekanga kwiindawo ezinobushushu obuphezulu.

Nika ingqalelo kwi-engangeni manzi ukuze uphephe ukuphelelwa ngamandla emva kokufunxwa ngamanzi.

Isitena seMagnesium

Iimpawu: ukuxhathisa okuphezulu kunye nokumelana okunamandla nokukhukuliseka kwe-alkaline.

Ukusetyenziswa: kusetyenziswa ezantsi nakwiziko le-oven ye-coke kunye nezinye iindawo ezidibana nezinto ze-alkaline.

Amanqaku:

Izitena zeMagnesium kulula ukuzifunxa amanzi kwaye kufuneka zigcinwe kakuhle ukuze zingafumi.

I-coefficient yokwandiswa kobushushu beetena ze-magnesium inkulu, kwaye kufuneka kuqwalaselwe iingxaki zokutshayiswa kobushushu.

Izitena ze-silicon carbide

Iimpawu: ukuqhuba okuphezulu kobushushu, ukumelana nokuguguleka, kunye nokumelana okuhle kakhulu nokuthuthumela kobushushu.

Ukusetyenziswa: kusetyenziswa kumnyango wesithando somlilo, kwisigqubuthelo sesithando somlilo, kwisitshisi kunye nezinye iindawo ze-oven ye-coke ezifuna ukutshatyalaliswa kobushushu ngokukhawuleza.

Amanqaku:

Izitena ze-silicon carbide zibiza kakhulu kwaye kufuneka zikhethwe ngokufanelekileyo.

Kuphephe ukudibana neegesi ezinamandla zokuxovula ukuze kuthintelwe ukuxovula.

Izinto zokuphosa ezirhabaxa

Iimpawu: ulwakhiwo olulula, ukuthembeka okuhle, kunye nokumelana okuhle kakhulu nobushushu.

Ukusetyenziswa: Isetyenziselwa ukulungiswa kwe-oven ye-coke, iindawo ezintsonkothileyo kunye nokuphoswa kwe-integral.

Amanqaku:

Ubungakanani bamanzi ongezelelweyo ngexesha lokwakha kufuneka bulawulwe ngokungqongqo ukuze kuthintelwe ukuphazamisa amandla.

Ubushushu kufuneka bunyuswe kancinci ngexesha lokubhaka ukuze kungabikho ukuqhekeka.

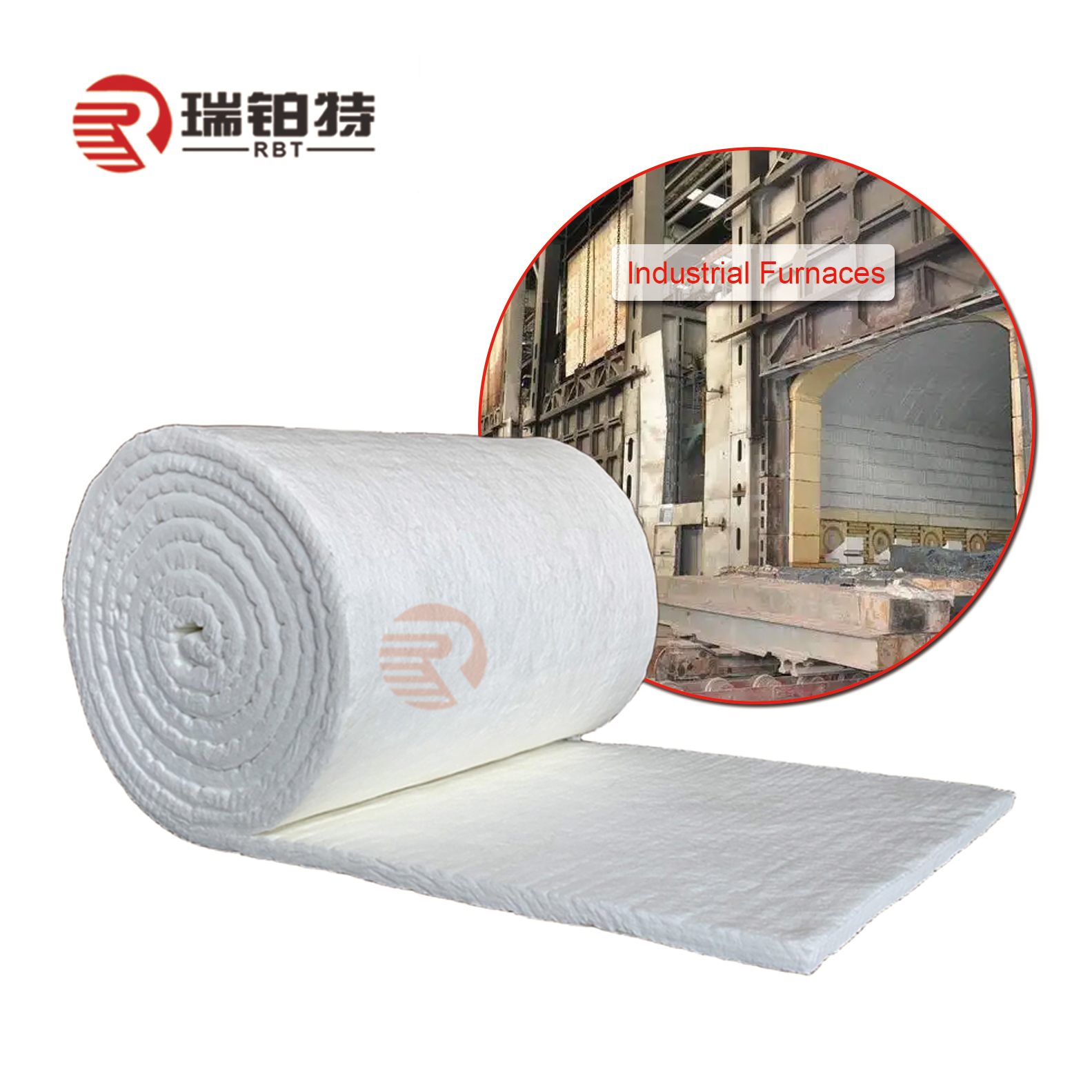

Ifayibha erhabaxa

Iimpawu: ubunzima obuphantsi, ubushushu obuhle, kunye nokumelana okuhle kakhulu nokutsha kobushushu.

Ukusetyenziswa: Isetyenziselwa umaleko wokukhusela ii-oven ze-coke ukunciphisa ukulahleka kobushushu.

Amanqaku:

Iifayibha ezirhabaxa azixhathisi kwimpembelelo yoomatshini kwaye kufuneka zithintelwe kumonakalo wangaphandle.

Ukuncipha kungenzeka xa kushushu kakhulu ixesha elide kwaye kufuna ukuhlolwa rhoqo.

Izitena zeCorundum

Iimpawu: ukurhawuzelela okuphezulu kakhulu (ngaphezu kwe-1800°C) kunye nokumelana okunamandla kokugqwala.

Ukusetyenziswa: Isetyenziswa kwiindawo ezishushu kakhulu nezinokukhukuliseka okuphezulu kwii-oven ze-coke, njengakwiindawo ezijikeleze izitshisi.

Ukulumkela:

Izitena zeCorundum zibiza kakhulu kwaye kufuneka zikhethwe ngokufanelekileyo.

Nika ingqalelo kubunzima beendawo zokudibanisa izitena ngexesha lokwakha.

2. Amanyathelo okhuseleko xa kusetyenziswa izinto ezithintela i-oven ye-coke

Ukukhetha izinto

Khetha izinto ezirhabaxa ngokufanelekileyo ngokweqondo lobushushu beendawo ezahlukeneyo ze-oven ye-coke, i-corrosive media (ene-asidi okanye i-alkaline) kunye nomthwalo woomatshini.

Kuphephe ukusebenzisa izinto ezithintela ubushushu obuphantsi kwiindawo ezinobushushu obuphezulu ukuthintela ukungasebenzi kakuhle kwezinto.

Umgangatho wokwakha

Lawula ngokungqongqo ubungakanani beendawo zokudibanisa izitena kwaye usebenzise udaka olufanelekileyo oluchaseneyo ukuqinisekisa ukuba ubuninzi bezakhiwo zokwakha buqinile.

Kwizixhobo ezikhatywayo ezinganyangekiyo, ulwakhiwo kufuneka lwenziwe ngokwemilinganiselo ukuze kuthintelwe ukongezwa kwamanzi amaninzi okuchaphazela amandla.

Umsebenzi wokubhaka kwi-oven

Ii-oven ze-coke ezisandula ukwakhiwa okanye ezilungisiweyo kufuneka zibhakwe. Ubushushu kufuneka bunyuswe kancinci ngexesha lokubhaka ukuze kuthintelwe ukuqhekeka okanye ukuxobuka kwezinto ezirhabaxa ngenxa yokutshintsha kobushushu ngequbuliso.

Ukugcinwa kwemihla ngemihla

Jonga rhoqo ukuguguleka, ukukhukuliseka kunye nokuqhekeka kwezinto ezichasayo ze-coke oven uze uzilungise ngexesha.

Kuphephe ukusebenza kwee-oven ze-coke kubushushu obugqithisileyo ukuze kuthintelwe ukonakala kwangethuba kwezinto ezichasayo.

Ukugcinwa nokugcinwa

Izinto ezivuselelayo kufuneka zigcinwe kwindawo eyomileyo ukuze kuthintelwe ukufuma (ingakumbi izitena ze-magnesia kunye nezinto ezivuselelayo ezivuselelayo).

Izinto ezirhabaxa ezenziwe ngezinto ezahlukeneyo mazigcinwe ngokwahlukeneyo ukuze kuthintelwe ukudideka.

Isishwankathelo

Izinto ezisetyenziswa rhoqo zokuchasana kwii-oven ze-coke ziquka izitena ze-silica, izitena ze-alumina eziphezulu, izitena zodongwe, izitena ze-magnesia, izitena ze-silicon carbide, izinto ezichasanayo zokuchasana, iifayibha zokuchasana kunye nezitena ze-corundum. Xa zisetyenziswa, izixhobo kufuneka zikhethwe ngokweemeko ezithile zokusebenza, kwaye kufuneka kuqwalaselwe umgangatho wokwakha, ukusebenza kwe-oven kunye nokugcinwa kwemihla ngemihla ukuze kwandiswe ubomi benkonzo ye-oven ye-coke.

Ixesha leposi: Matshi-05-2025