Kwiindlela ezahlukeneyo zokudibanisa imveliso yemizi-mveliso,ukuphosa izitena zentsimbi, njengezinto eziphambili ezineempawu ezikhethekileyo, zidlala indima engenakutshintshwa. Ngenxa yokumelana kwazo nobushushu obuphezulu, ukumelana nokugqwala kunye nezinye iimpawu, ziye zasetyenziswa kakhulu kwiindawo ezininzi, zibonelela ngesiqinisekiso esibalulekileyo senkqubela phambili ethe tye yemveliso yemizi-mveliso.

Indima Ebalulekileyo Ekubunjweni Kwesinyithi

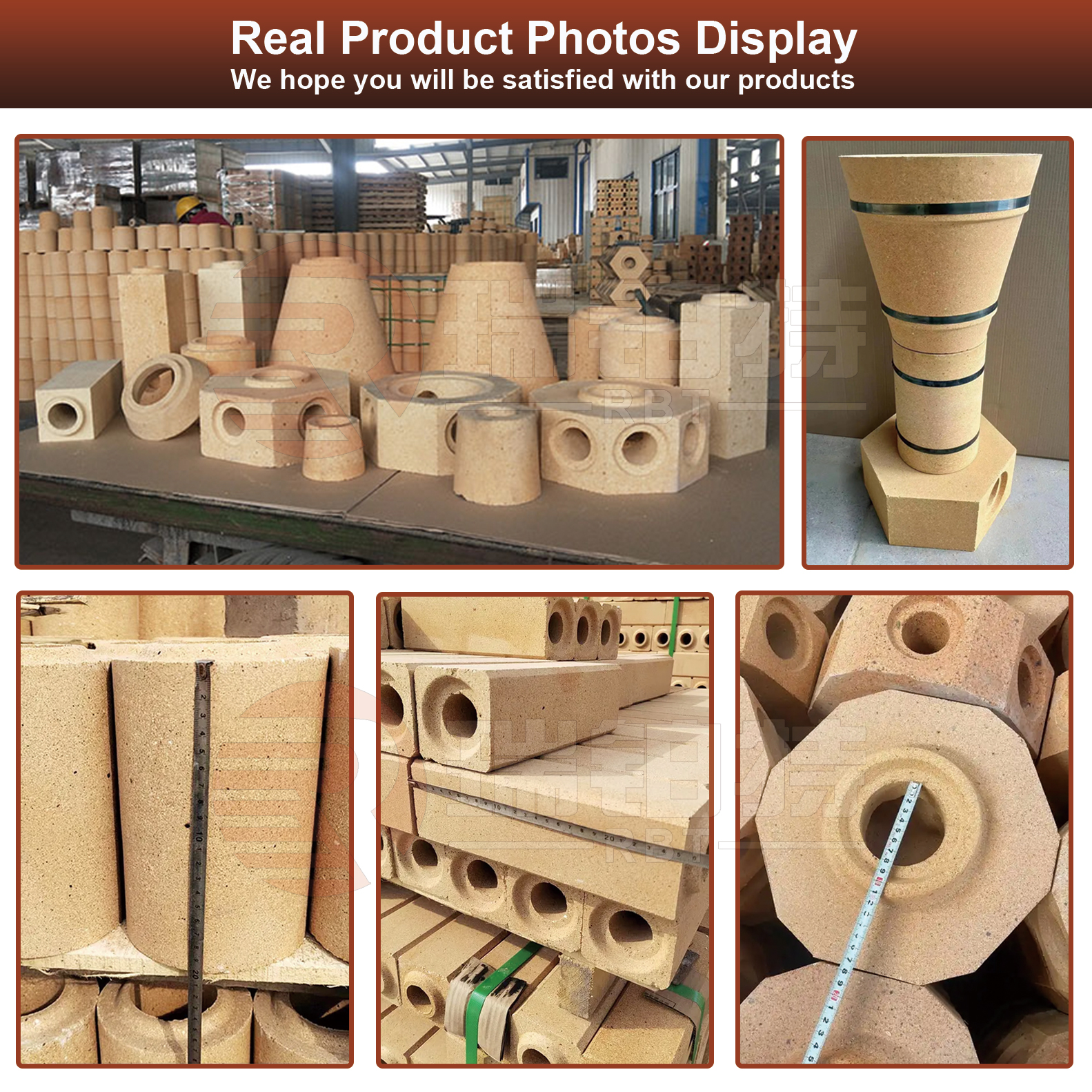

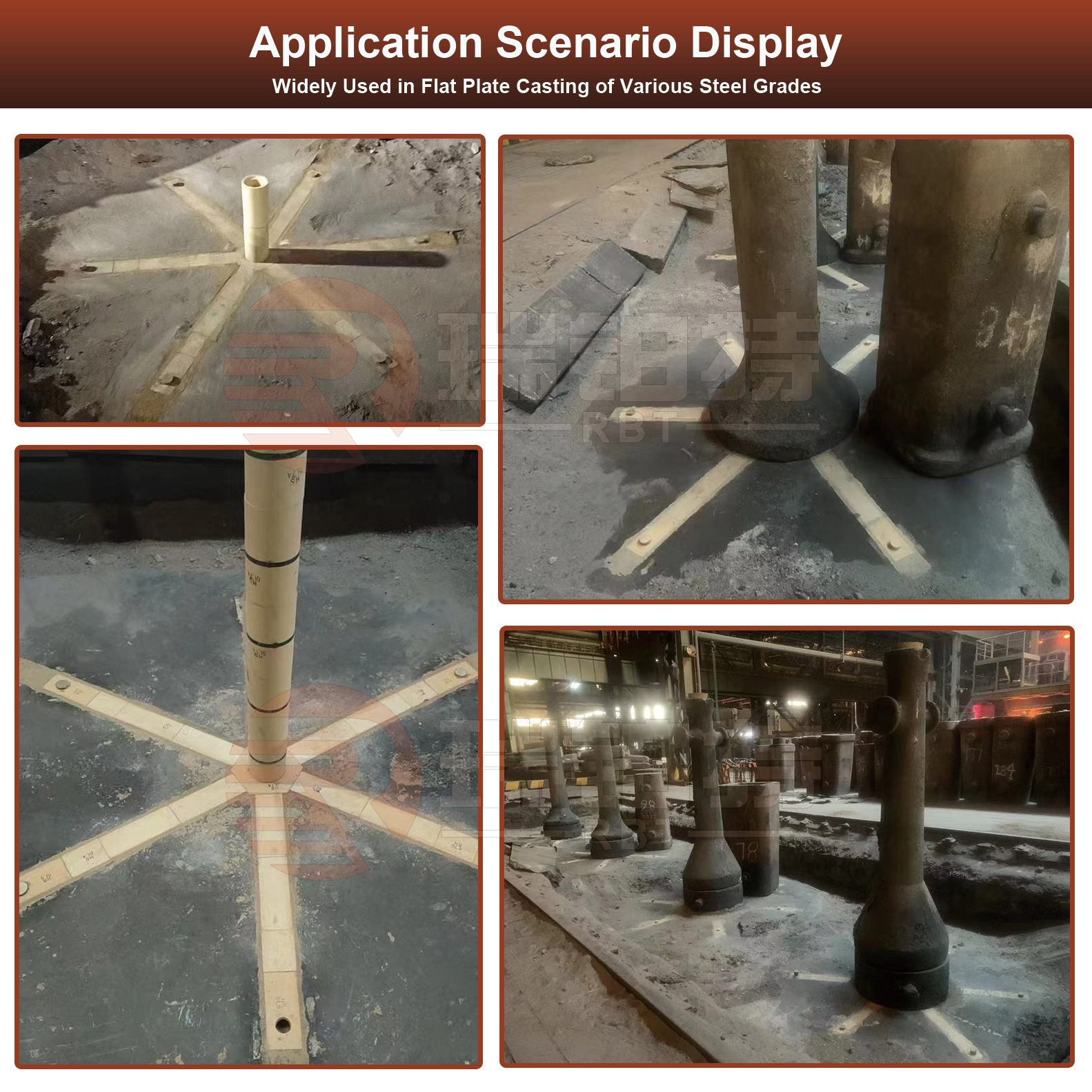

Kwishishini lokuphosa isinyithi, izitena zentsimbi eziphoswayo zizinto eziphambili ezifunekayo. Injongo yazo ephambili kukusebenza njengomjelo wentsimbi ephosweyo ukuba ihambe ukusuka kwiladle ukuya kwi-ingot mold kwinkqubo yokuphosa esezantsi. Ngokukodwa, izitena zentsimbi eziphosweyo zakhiwe kwimiqolo yepleyiti yesiseko se-ingot casting, enye isiphelo iqhagamshelwe kwisitena sokusasazwa kwesinyithi kwaye enye isiphelo siqhagamshelwe kwi-ingot mold, okwenza indlela ephambili yokuhamba kwesinyithi esiphosweyo. Ke ngoko, zihlala zibizwa ngokuba "zizitena ze-tundish" ngabantu abangaphakathi.

Ngexesha lenkqubo yokuthulula intsimbi enyibilikisiweyo, ubushushu bentsimbi enyibilikisiweyo eshushu kakhulu buphezulu kakhulu, budla ngokufikelela kumawaka eedigri zeCelsius, nto leyo ebeka iimfuno eziphezulu kakhulu kukumelana nobushushu obuphezulu kwezitena zentsimbi eziphoswayo. Kwangaxeshanye, intsimbi enyibilikisiweyo iya kuba nefuthe elinamandla kunye nokukhuhla umzimba wezitena ngexesha lenkqubo yokuhambahamba, kwaye intsimbi enyibilikisiweyo ngokwayo iya kuba neempembelelo ezithile zeekhemikhali kunye nomzimba wezitena. Izitena zentsimbi eziphoswayo ezisemgangathweni ophezulu zinokumelana nezi mvavanyo kwaye ziqinisekise ukuhamba kakuhle kwentsimbi enyibilikisiweyo. Umngxuma wayo wangaphakathi uthambile, onokunciphisa ngempumelelo ukumelana xa intsimbi enyibilikisiweyo ihamba, uphephe ukuhamba okuguquguqukayo ngexesha lokuhamba kwentsimbi enyibilikisiweyo, ngaloo ndlela unciphise ukuveliswa kweziphene ezifana namaqamza kunye nokufakwa kwi-ingot, kwaye uphucule umgangatho we-ingot. Nokuba kukuphoswa okuthe tyaba kwentsimbi engagqwaliyo, intsimbi ye-alloy okanye intsimbi eqhelekileyo yekhabhoni, izitena zentsimbi eziphoswayo zinokulungiswa kakuhle ukubonelela ngenkxaso ezinzileyo yokuphoswa kweentlobo ezahlukeneyo zentsimbi.

Izinto Ezibalulekileyo Zokugquma Izibane Zemizi-mveliso

Izitofu zoshishino zizixhobo eziphambili kwiinkqubo ezininzi zemveliso yemizi-mveliso, ezifana nezitofu zokuqhuma kunye nezitofu zokuqhuma ezishushu kwishishini lesinyithi nentsimbi, kunye nezitofu zokusabela kwishishini leekhemikhali. Ezi zitofu zihlala zifuna ukusebenza kwiindawo ezinobushushu obuphezulu, kwaye imeko yangaphakathi inzima kakhulu. Izitena zentsimbi ezibunjiweyo, ezinobungqingili bazo obuphezulu kunye nokumelana nokugqwala, ziye zaba lukhetho olufanelekileyo lokufakwa kwefenitshala yezitofu zoshishino.

Ukusebenzisa izitena zentsimbi njengemiphetho yezitovu zoshishino kunokumelana ngempumelelo nokubhaka okushushu kakhulu kwisitovu kunye nokukhukuliseka kweegesi ezahlukeneyo ezirhabaxa kunye nolwelo. Kungakhusela ulwakhiwo lweqokobhe lesitovu, kuthintele ukuguquka kunye nokonakala komzimba wesitovu ngenxa yobushushu obuphezulu, kwaye kwandise ubomi benkonzo yesitovu. Kwangaxeshanye, izitena zentsimbi ezirhabaxa zisebenza kakuhle ekugqumeni ubushushu, nto leyo enokunciphisa ukulahleka kobushushu kwisitovu, iphucule ukusebenza kakuhle kwamandla, kwaye inciphise ukusetyenziswa kwamandla kwimveliso. Kwezinye izitovu ezifuna ulawulo oluchanekileyo lobushushu, ukusebenza okuzinzileyo kwezitena zentsimbi ezirhabaxa kunokunceda ukugcina ubushushu obufanayo kwisitovu, ukuqinisekisa uzinzo lwenkqubo yemveliso, kwaye ngaloo ndlela kuphucule umgangatho wemveliso.

Ukusetyenziswa Kokhuseleko Kwiinkqubo Ezikhethekileyo Zemibhobho

Kweminye imveliso yemizi-mveliso, kukho iinkqubo ezikhethekileyo zemibhobho yokuthutha izixhobo zombane ezinobushushu obuphezulu nezinoxinzelelo oluphezulu (ezifana nomphunga obushushu obuphezulu, isinyithi esinyibilikisiweyo, njl.njl.). Ezi zixhobo zombane zihlala zikwimeko enzima yokusebenza ixesha elide kwaye zinomngcipheko wokukhuhla, ukugqwala kunye nomonakalo obushushu obuphezulu yizixhobo zombane, nto leyo echaphazela ukhuseleko kunye nobomi benkonzo yemibhobho.

Izitena zentsimbi eziphoswayo zingasetyenziselwa ukukhusela iindawo ezibalulekileyo zezi nkqubo zemibhobho ekhethekileyo. Ngokwakha izitena zentsimbi kwiindawo ezithile ngaphakathi okanye ngaphandle kombhobho, umqobo oqinileyo wokukhusela unokwenziwa ukumelana nempembelelo ethe ngqo kunye nokukhukuliseka komedium kumbhobho. Ingakumbi kwiindawo zokujika kunye neendawo ezidityanisiweyo zombhobho, ezidla ngokuguguleka nokubola, isiphumo sokukhusela sokwenziwa kwezitena zentsimbi sibonakala ngakumbi. Inganciphisa ngempumelelo izinga lokuguguleka kombhobho, inciphise umngcipheko wokuvuza kombhobho, iqinisekise ukusebenza ngokukhuselekileyo nangokuzinzileyo kwenkqubo yombhobho, inciphise ukuphazamiseka kwemveliso okubangelwa kukugcinwa kombhobho, kwaye iphucule ukusebenza kakuhle kwemveliso.

Izitena zentsimbi eziphoswayo, ezineempawu zazo ezizodwa, zinezicelo ezibalulekileyo ekuphosweni kwesinyithi, kwiifenitshala zoshishino, kwiinkqubo zemibhobho ekhethekileyo nakwezinye iindawo. Ngophuhliso oluqhubekayo lwetekhnoloji yemveliso yemizi-mveliso, iimfuno zokusebenza kwezitena zentsimbi eziphoswayo ziyanda rhoqo. Kwixesha elizayo, uluhlu lwazo lwezicelo kulindeleke ukuba lukhule ngakumbi, lubonelele ngenkxaso yezinto ezithembekileyo kwiindawo ezininzi zoshishino. Ukuba ujonge izinto ezifanelekileyo ezimelana nobushushu obuphezulu nezimelana nokugqwala kwiiprojekthi zoshishino ezinxulumene noko, ukuphoswa kwezitena zentsimbi ngokuqinisekileyo lukhetho olusemgangathweni olufanele ukuqwalaselwa.

Ixesha lokuthumela: Agasti-01-2025