Kwihlabathi leenkqubo zoshishino ezishushu kakhulu, ukukhetha izinto ze-oven kunokwenza okanye kuphazamise ukusebenza kakuhle, umgangatho, kunye nobude bemisebenzi yakho. Phakathi kwezi zinto zibalulekileyo, iipleyiti ze-oven ze-silicon carbide zibonakala njengesisombululo esitshintsha umdlalo, zibonelela ngeenzuzo ezininzi ezinokuguqula ukusebenza kwe-oven yakho.

Ukumelana nobushushu okungaqhelekanga

I-silicon carbide (i-SiC) yaziwa ngeempawu zayo ezimangalisayo zokumelana nobushushu. Iipleyiti ze-kiln ezenziwe ngale nto iphambili zinokumelana nobushushu obugqithisileyo, zihlala zifikelela kwi-1600°C okanye ngaphezulu kwezinye izicelo ezikhethekileyo. Olu bushushu buphezulu luqinisekisa ukuba iipleyiti zigcina ulwakhiwo lwazo lusemgangathweni, nokuba zikwiindawo ezifuna kakhulu i-kiln. Nokuba utshisa i-ceramics, unyibilikisa iintsimbi, okanye uqhuba ezinye iinkqubo zobushushu obuphezulu, iipleyiti ze-kiln ze-silicon carbide zibonelela ngeqonga elithembekileyo nelizinzileyo elingayi kugoba, liqhekeke, okanye liwohloke phantsi kobushushu obuphezulu.

Ukuqhuba Okuphezulu Kobushushu

Enye yezona nzuzo ziphambili zeepleyiti ze-silicon carbide kiln kukuba ziqhuba kakuhle kakhulu. I-SiC inokuqhuba kakuhle kakhulu xa ithelekiswa nezixhobo ze-kiln zemveli ezifana nodongwe olungenambala okanye i-alumina. Oku kuthetha ukuba ubushushu busasazwa ngokukhawuleza nangokulinganayo kumphezulu wepleyiti, nto leyo enciphisa ubushushu ngaphakathi kwi-kiln. Ngenxa yoko, iimveliso zakho ziphathwa ngobushushu obufanayo, nto leyo ekhokelela ekuphuculweni komgangatho, ukunciphisa amaxesha okudubula, kunye nokusebenza kakuhle kwamandla. Ngeepleyiti ze-kiln ze-silicon carbide, ungafumana iziphumo ezihambelanayo ngakumbi kwimisebenzi ye-kiln yakho, ngelixa ukonga iindleko zamandla ekuhambeni kwexesha.

Amandla Abalaseleyo Oomatshini

Ukongeza kwiipropati zazo zokuhambisa ubushushu kunye nobushushu, iipleyiti ze-silicon carbide kiln zinamandla amangalisayo oomatshini. Ziyakwazi ukumelana noxinzelelo loomatshini, kubandakanya ubunzima bemithwalo enzima kunye nefuthe lezinto ezibekwayo okanye ezisuswayo kwi-oven. La mandla aqinisekisa ukuba iipleyiti zihlala ixesha elide, nokuba zikwiindawo zoshishino apho zinokusetyenziswa rhoqo kwaye ziphathwa khona. Amandla aphezulu oomatshini e-silicon carbide akwenza kube nokwenzeka ukuyila iipleyiti ze-oven ezincinci nezikhaphukhaphu ngaphandle kokunciphisa ukusebenza, okunokuba luncedo ekwenzeni ngcono indawo ye-oven kunye nokunciphisa ubunzima bezixhobo ngokubanzi.

Ukumelana kakuhle kweekhemikhali

Iinkqubo ze-oven yemizi-mveliso zihlala ziquka ukuvezwa kwiikhemikhali ezahlukeneyo, iigesi, kunye nezinto ezirhabaxa. Iipleyiti ze-oven ze-silicon carbide zibonelela ngokumelana okuhle kweekhemikhali, okwenza zifaneleke ukusetyenziswa kwiindawo apho izinto zemveli zinokubola okanye zonakale ngokuhamba kwexesha. Nokuba yi-atmospheres ene-asidi okanye ye-alkaline efumaneka rhoqo kwiinkqubo ezithile zokudubula okanye ubukho beegesi ezisebenzayo kwizicelo zokunyibilika kwesinyithi, iipleyiti ze-silicon carbide zinokumelana nale mingeni yeekhemikhali ngaphandle kokulahlekelwa bubunyani bazo. Olu kumelana neekhemikhali alupheleli nje ekwandiseni ubomi beepleyiti ze-oven kodwa lukwanceda ekugcineni indawo ye-oven ecocekileyo nengenangcolisi, ebalulekileyo ekuveliseni iimveliso ezisemgangathweni ophezulu.

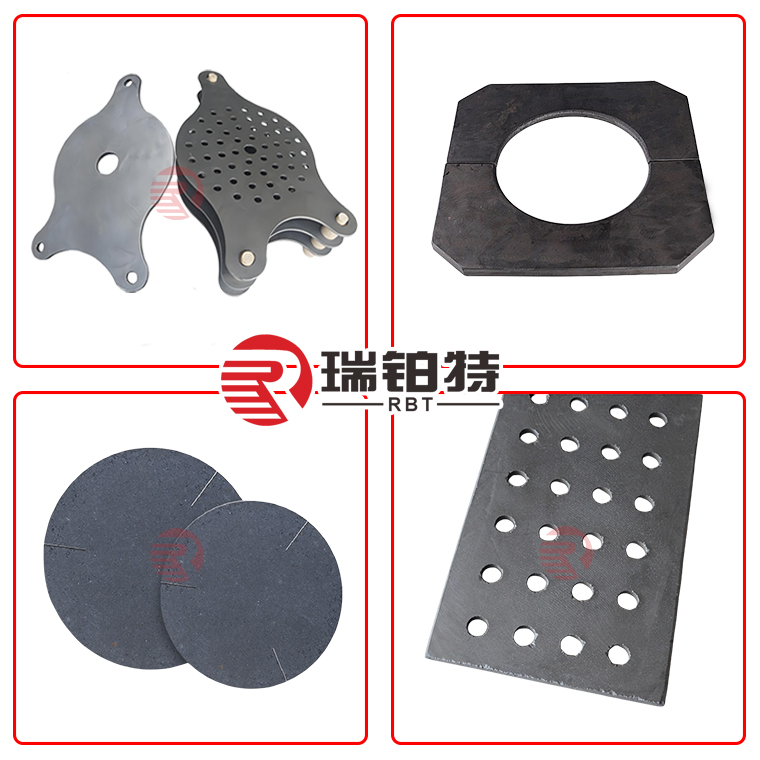

Izicelo Ezininzi

Iimpawu ezikhethekileyo zeepleyiti ze-silicon carbide kiln zizenza zilungele ukusetyenziswa ngeendlela ezahlukeneyo kumashishini amaninzi. Kwishishini le-ceramics, zisetyenziswa kakhulu njengeepleyiti zokuxhasa ukutshisa iithayile ze-porcelain ezithambileyo, zobumba, kunye neze-ceramic. Uzinzo lobushushu obuphezulu kunye nokusasazwa kobushushu obufanayo okunikezelwa ziipleyiti ze-silicon carbide kuqinisekisa ukuba iimveliso ze-ceramic zitshiswa ngokulinganayo, nto leyo ebangela imibala efanayo, ubume, kunye nokugqitywa kwe-glaze.

Kwishishini lesinyithi, iipleyiti ze-silicon carbide kiln zidlala indima ebalulekileyo kwiinkqubo ezinje ngokunyibilika kwesinyithi, ukuphoswa, kunye nonyango lobushushu. Zinokumelana nobushushu obukhulu kunye nendalo yokubola kweentsimbi ezinyibilikisiweyo, zibonelela ngomphezulu othembekileyo wokubamba nokucubungula izinto zesinyithi. Ukongeza, kwishishini le-elektroniki, iipleyiti ze-silicon carbide kiln zisetyenziswa kwimveliso yee-semiconductors kunye nezinye izinto ze-elektroniki, apho ulawulo oluchanekileyo lobushushu kunye nendawo yokutshisa ecocekileyo kubalulekile.

Ukukhetha iiPlates zeSilicon Carbide Kiln ezifanelekileyo

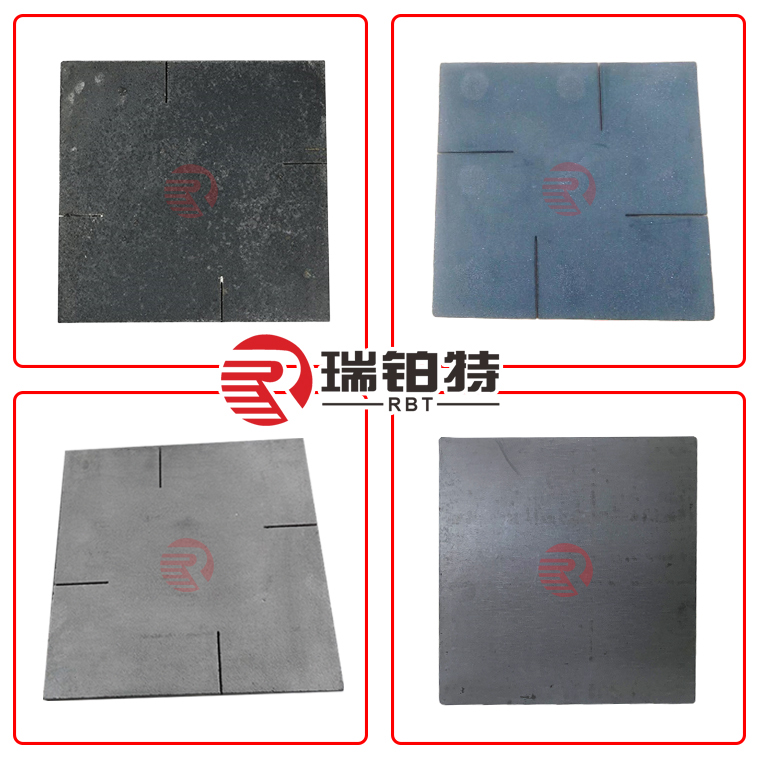

Xa ukhetha iipleyiti ze-silicon carbide kiln ukuze uzisebenzise, kubalulekile ukuqwalasela izinto ezininzi. Okokuqala, kufuneka umisele iimfuno zobushushu eziphezulu zenkqubo yakho ye-kiln. Amanqanaba ahlukeneyo e-silicon carbide ayafumaneka, ngalinye linomlinganiselo walo wokunyamezela ubushushu, ngoko ke ukukhetha umgangatho ofanelekileyo kubalulekile ukuqinisekisa ukusebenza kakuhle.

Kufuneka uqwalasele ubungakanani kunye nokuma kweepleyiti ze-oven. Kufuneka zilingane ngokuchanekileyo nobukhulu be-oven yakho ukuqinisekisa ukusasazwa kobushushu ngokufanelekileyo kunye nokusebenza ngokufanelekileyo. Ukongeza, izinto ezinje ngokugqitywa komphezulu weepleyiti, ukuvuleka kwazo, kunye nokuhambelana kwazo nezinto ezicutshungulwa kwi-oven kufuneka ziqwalaselwe.

Ukuqukumbela, iipleyiti ze-silicon carbide kiln zibonelela ngeenzuzo ezininzi ezinokuphucula kakhulu ukusebenza kunye nemveliso yemisebenzi yakho ye-oven. Ngenxa yokumelana kwazo nobushushu okugqwesileyo, ukuqhuba kakuhle kobushushu, amandla abalaseleyo oomatshini, kunye nokumelana okugqwesileyo kweekhemikhali, ezi pleyiti zisisombululo esithembekileyo nesiguquguqukayo kwiintlobo ngeentlobo zezicelo zoshishino ezishushu kakhulu. Ngokukhetha iipleyiti ze-silicon carbide kiln ezifanelekileyo kwiimfuno zakho kunye nokusebenza nomthengisi othembekileyo, ungavula amandla apheleleyo e-oven yakho kwaye uthabathe iinkqubo zakho zoshishino uye kwinqanaba elilandelayo.

Ixesha leposi: Julayi-07-2025