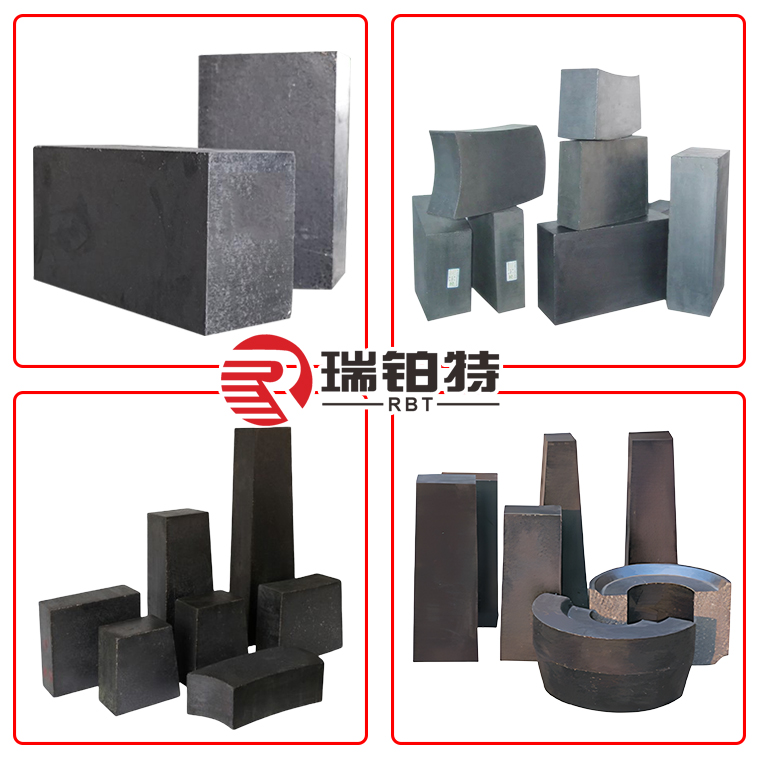

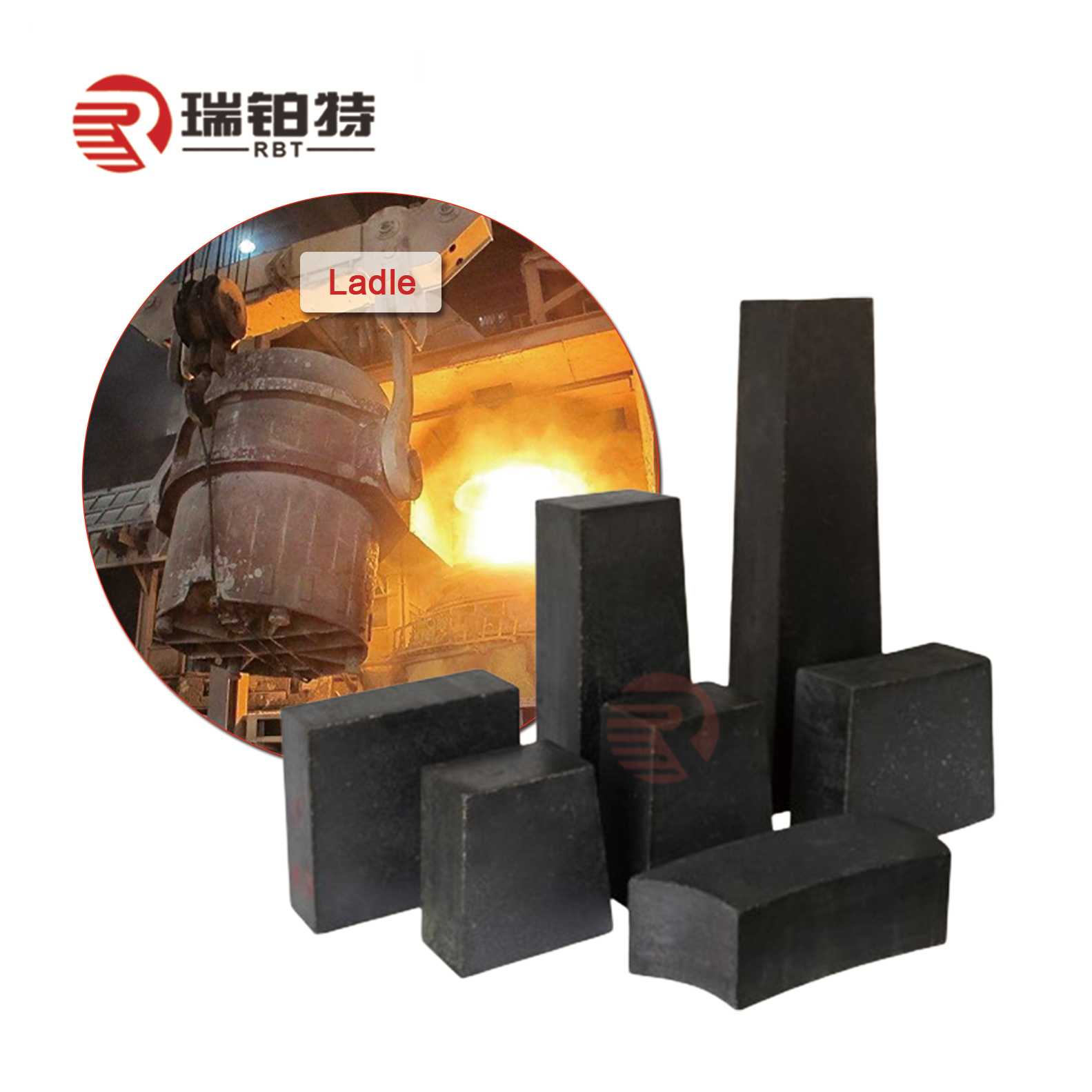

Isitena sekhabhoni seMagnesiumsisixhobo esichasene nekhabhoni esingatshiyo esenziwe nge-alkaline oxide enyibilikayo kakhulu, i-magnesium oxide (inqanaba lokunyibilika elingama-2800℃) kunye nezinto zekhabhoni ezinyibilikayo kakhulu (ezifana ne-graphite) ekunzima ukumanziswa yi-slag njengezinto eziphambili, kongezwa izongezo ezahlukeneyo ezingezizo i-oxide, kwaye umgca we-slag we-ladle udityaniswe ne-carbon binder. Isitena sekhabhoni seMagnesium sisetyenziswa kakhulu kwi-lining ye-converters, ii-AC arc furnaces, ii-DC arc furnaces, kunye ne-slag lines zee-ladles.

Iimbonakalo

Ukumelana nobushushu obuphezulu:Izitena zekhabhoni zeMagnesium zinokuhlala zizinzile kwiindawo ezinobushushu obuphezulu kwaye zikwazi ukumelana nobushushu obuphezulu kakhulu.

Ukusebenza kokukhukuliseka kwe-slag:Izinto zekhabhoni zinokumelana okuhle kakhulu nokukhukuliseka kwe-asidi kunye ne-alkali slag, ngoko ke izitena zekhabhoni ze-magnesium zinokumelana ngcono nokukhukuliseka kweekhemikhali yintsimbi enyibilikisiweyo kunye ne-slag.

Ukuqhuba kobushushu:Izinto zekhabhoni zinomoya ophezulu wokuqhuba ubushushu, zinokuqhuba ubushushu ngokukhawuleza, kwaye zinciphise umonakalo woxinzelelo lobushushu emzimbeni wezitena.

Ukumelana noxinzelelo lobushushu:Ukongezwa kwegrafiti kuphucula ukumelana nobushushu kwezitena ze-magnesium carbon, ezinokumelana notshintsho olukhawulezileyo lobushushu kwaye zinciphise umngcipheko wokuqhekeka.

Amandla oomatshini: Amandla aphezulu e-magnesia kunye nokuqina okuphezulu kwe-graphite kwenza izitena ze-magnesia carbon zibe namandla aphezulu oomatshini kunye nokumelana nempembelelo.

Iindawo zokusetyenziswa

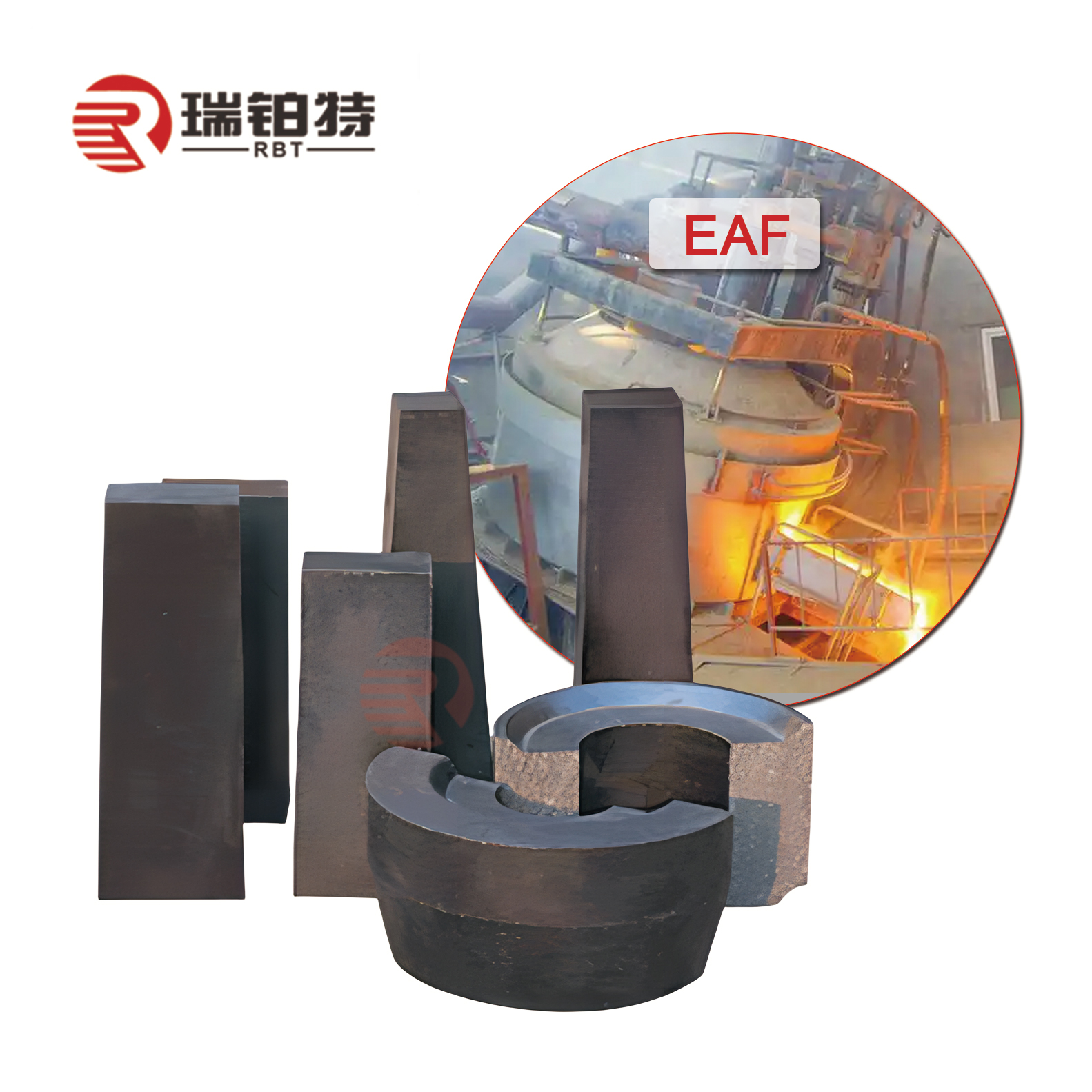

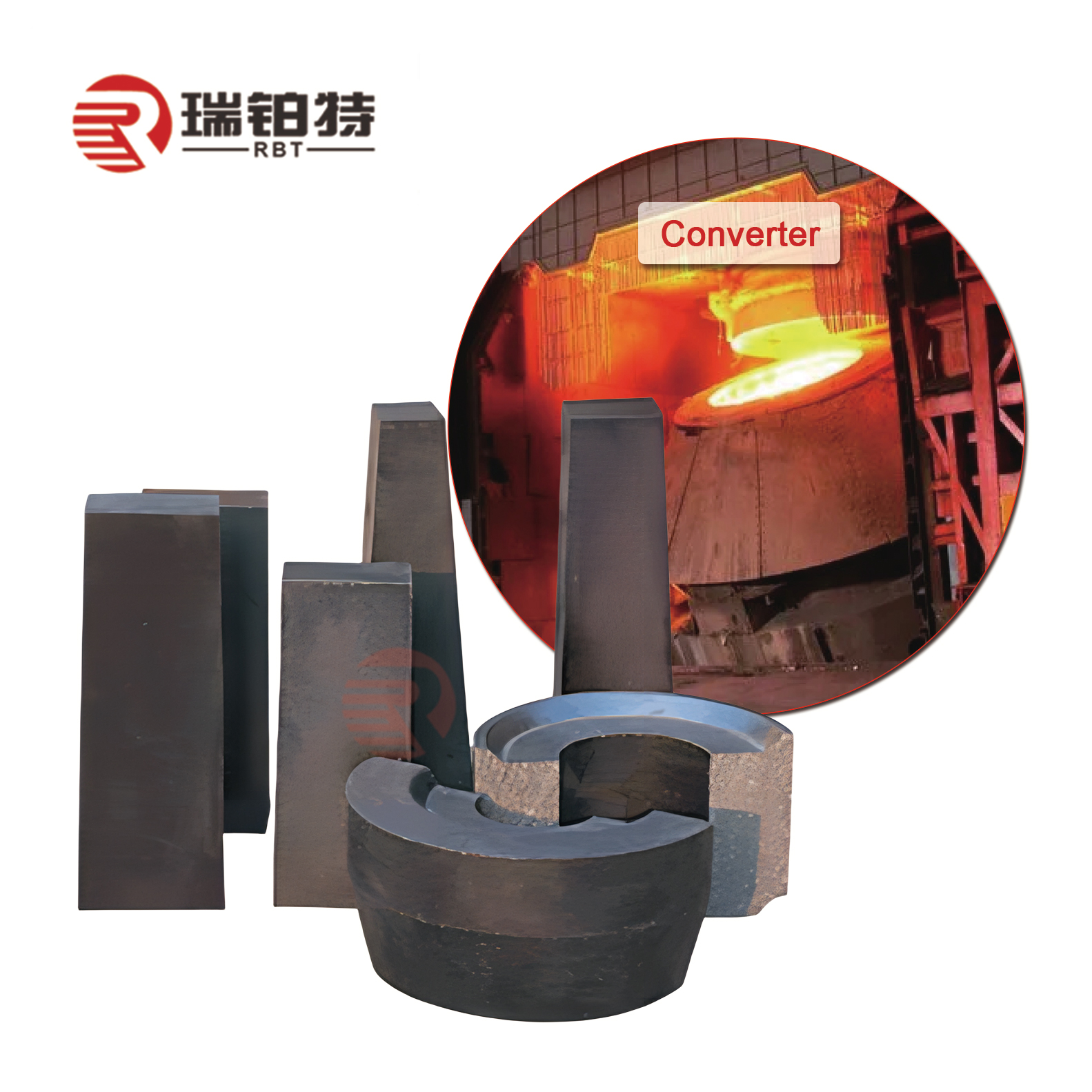

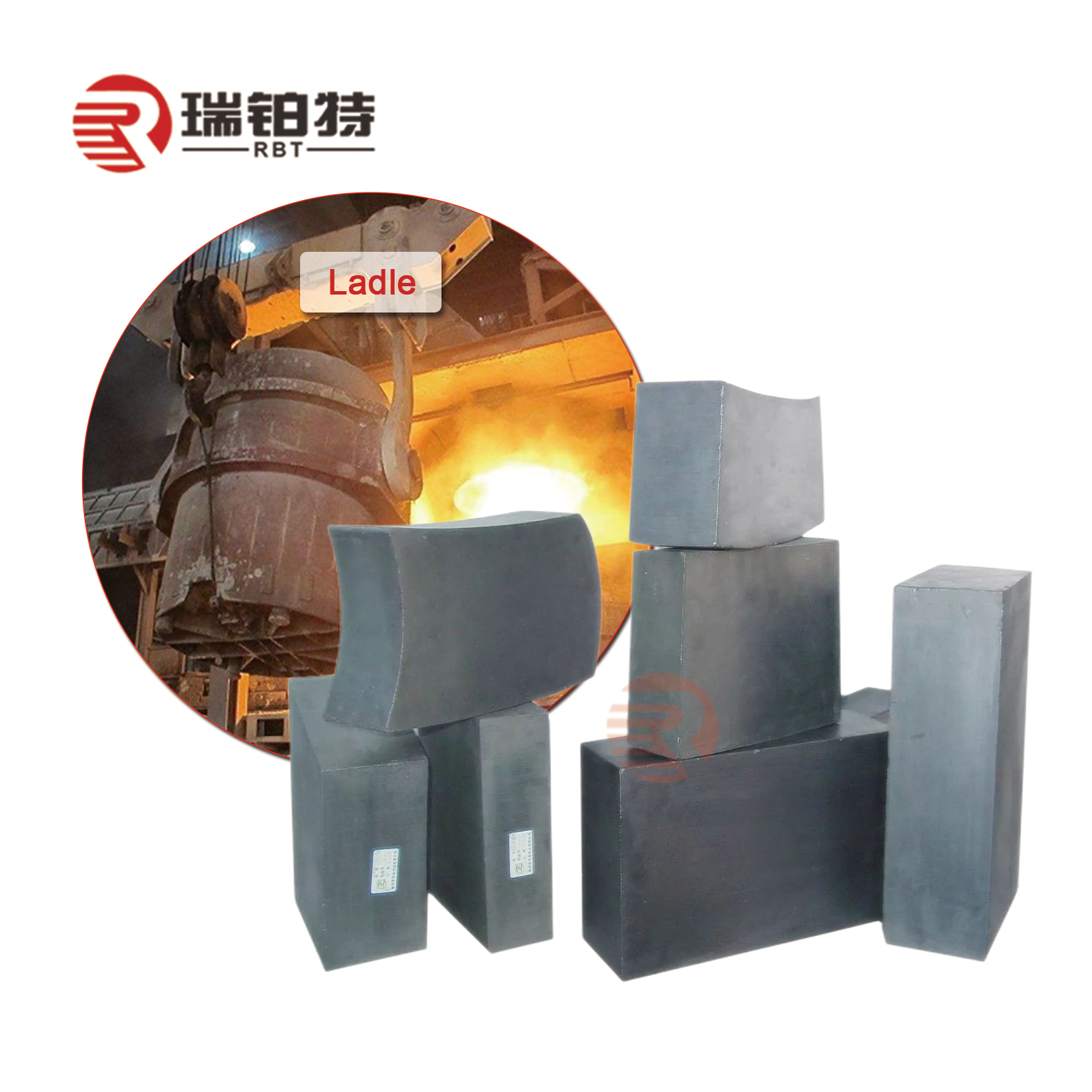

Izitena zekhabhoni zeMagnesium zisetyenziswa kakhulu kwiindawo eziphambili ezichaseneyo kumashishini ashushu kakhulu, ingakumbi ekunyibilikiseni intsimbi:

Isiguquli:Isetyenziswa kwi-lining, umlomo wesithando somlilo, kunye nendawo yomgca we-slag yesiguquli, esinokumelana nokukhukuliseka kwentsimbi enyibilikisiweyo kunye ne-slag.

Isithando sombane se-arc:Isetyenziswa eludongeni lwesithando somlilo, ezantsi kwesithando somlilo nakwezinye iindawo zesithando somlilo se-arc sombane, esinokumelana nobushushu obuphezulu kunye nokukhuhla.

Iladle:Isetyenziswa kwi-lining kunye ne-oven cover ye-ladle, imelana nokuguguleka kweekhemikhali zentsimbi enyibilikisiweyo kwaye yandisa ubomi benkonzo.

Isithando sokucoca:Ifanelekile kwiindawo eziphambili zee-oven zokucoca ezifana nee-oven ze-LF kunye nee-oven ze-RH, ihlangabezana neemfuno zeenkqubo zokucoca ezishushu kakhulu.

Ixesha leposi: Jan-21-2025