I-Refractory Castable

Ingcaciso yeMveliso

Izinto zokuphosa ezirhabaxazingumxube wee-aggregates ezichasayo, iipowders kunye nee-binders. Emva kokongeza amanzi okanye ezinye izinto ezimanzi, zifanelekile ukwakhiwa ngeendlela zokugalela kunye nokungcangcazela. Zingalungiswa zibe ziinxalenye ezilungiselelwe kwangaphambili ezineemilo kunye nobukhulu obuthile bokwakha ii-linings ze-furnace zemizi-mveliso. Ukuze kuphuculwe iipropati zomzimba nezekhemikhali kunye nokusebenza kokwakhiwa kwee-castables ezichasayo, kudla ngokufakwa izixa ezifanelekileyo ze-admixtures, ezifana nee-plasticizers, ii-dispersants, ii-accelerators, ii-retarders, ii-expansion agents, ii-debonding-gelling agents, njl. Ukongeza, kwii-castables ezichasayo ezisetyenziswa kwiindawo ezineemandla ezinkulu zoomatshini okanye i-thermal shock enamandla, ukuba kongezwa isixa esifanelekileyo sefayibha yentsimbi engagqwaliyo, ukuqina kwezinto kuya kwanda kakhulu. Kwi-castable echasayo echasayo, ukuba kongezwa iifayibha ezingaphiliyo, ayinako nje kuphela ukomeleza ukuqina, kodwa ikwanceda ukuphucula iipropati zayo zokuthintela ubushushu. Ekubeni ukwakheka kwezinto ezisisiseko zezinto ezisetyenziswayo ezingafunekiyo (ezifana nee-aggregates kunye nee-powders, i-admixtures, i-binders kunye ne-admixtures), inkqubo yokuxinana kunye nokuqina, iindlela zokwakha, njl.njl., zifana nekhonkrithi kubunjineli bokwakha, yayikhe yabizwa ngokuba yiikhonkrithi enganyangekiyo.

Isalathiso seMveliso

| Igama lemveliso | I-Castable Elula | ||||||

| Ubushushu obulinganiselweyo bokusebenza | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110℃ Ubuninzi boMzimba (g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Imodulus yokuqhekeka (i-MPa) ≥ | 110℃×24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100℃×3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400℃×3h | ― | ― | 3 | 10.8 | 8.1 | ||

| Amandla okutyumza abandayo (i-MPa) ≥ | 110℃×24h | 8 | 8 | 11 | 12 | 10 | |

| 1100℃×3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400℃×3h | ― | ― | 15 | 22 | 14 | ||

| Utshintsho olusisigxina lomgca (%) | 1100℃×3h | -0.65 1000℃×3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400℃×3h | ― | ― | -0.8 | -0.55 | -0.45 | ||

| Ukuqhuba kweThermal (W/mk) | 350℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| I-Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| I-Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

| Igama lemveliso | I-Castable yesamente ephantsi | |||||

| ISALATHISO | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Ubushushu obulinganiselweyo bokusebenza | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Ubuninzi bobuninzi (g/cm3) 110℃ × 24h≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Amandla Okugoba Okubandayo 110℃×24h(MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Amandla okutyumza abandayo (MPa) ≥ | 110℃×24h | 25 | 30 | 35 | 35 | 40 |

| I-CT℃×iiyure ezi-3 | 50 1300℃×3h | 55 1350℃×3h | 60 1400℃×3h | 40 1400℃×3h | 70 1400℃×3h | |

| Utshintsho olusisigxina lomgca @CT℃ × 3h(%) | -0.5~+0.5 1300℃ | -0.5~+0.5 1350℃ | 0~+0.8 1400℃ | 0~+0.8 1400℃ | 0~+1.0 1400℃ | |

| Ukumelana noTshabalalo oluTshisayo (1000℃ amanzi) ≥ | ― | ― | ― | 20 | ― | |

| I-Al2O3(%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| I-CaO(%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| I-Fe2O3(%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Igama lemveliso | Amandla aphezulu angenakuphoswa | |||||

| ISALATHISO | HS-50 | HS-60 | HS-70 | HS-80 | HS-90 | |

| Ubushushu boMda wokusebenza (℃) | 1400 | 1500 | 1600 | 1700 | 1800 | |

| 110℃ Ubuninzi boMzimba (g/cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| Imodulus yokuqhekeka (MPa) ≥ | 110℃×24h | 6 | 8 | 8 | 8.5 | 10 |

| 1100℃×3h | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400℃×3h | 8.5 1300℃×3h | 9 | 9.5 | 10 | 15 | |

| Amandla okutyumza abandayo (MPa) ≥ | 110℃×24h | 35 | 40 | 40 | 45 | 60 |

| 1100℃×3h | 40 | 50 | 45 | 50 | 70 | |

| 1400℃×3h | 45 1300℃×3h | 55 | 50 | 55 | 100 | |

| Utshintsho olusisigxina lomgca (%) | 1100℃×3h | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400℃×3h | -0.45 1300℃×3h | -0.4 | -0.3 | -0.3 | -0.1 | |

| I-Al2O3(%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| I-CaO(%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| I-Fe2O3(%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

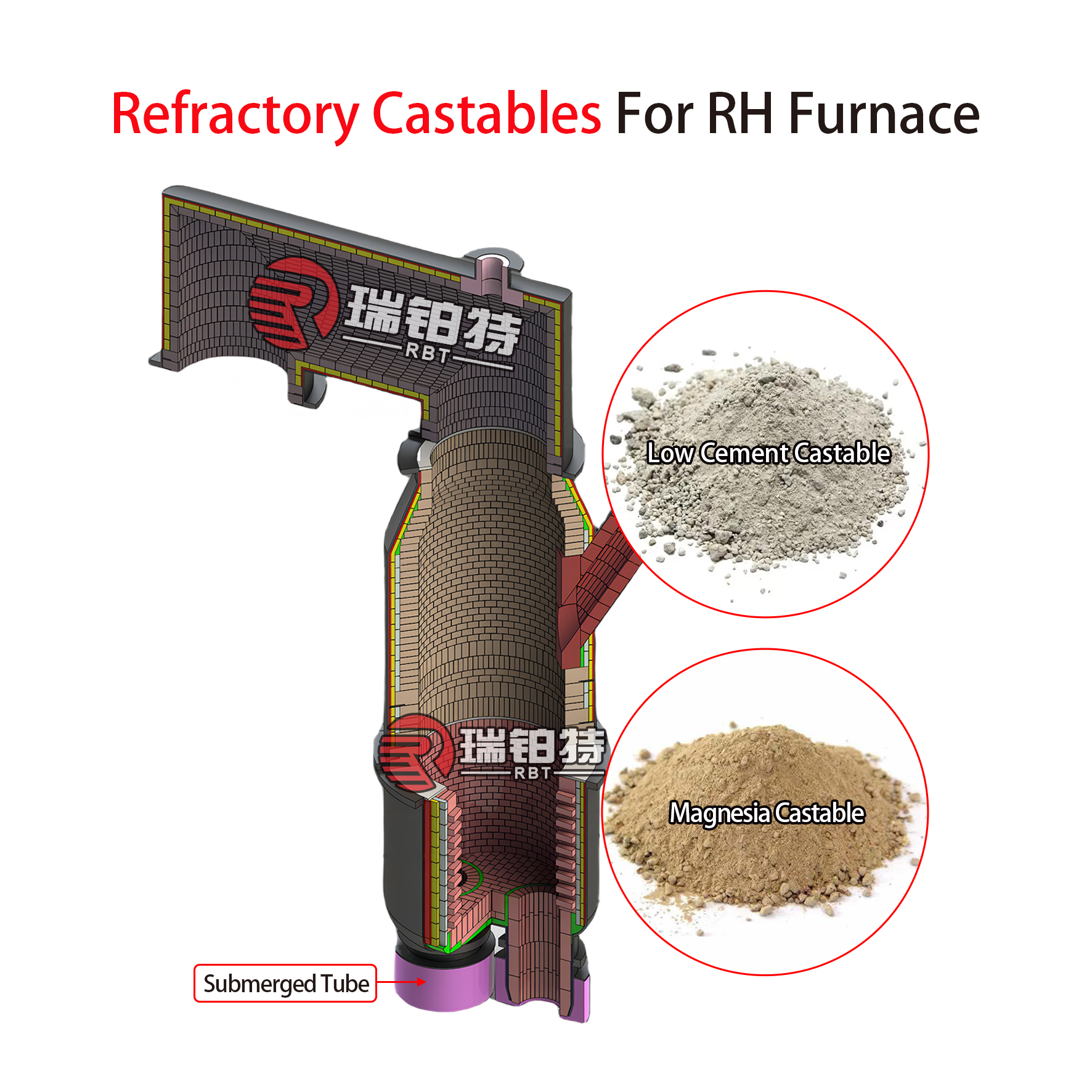

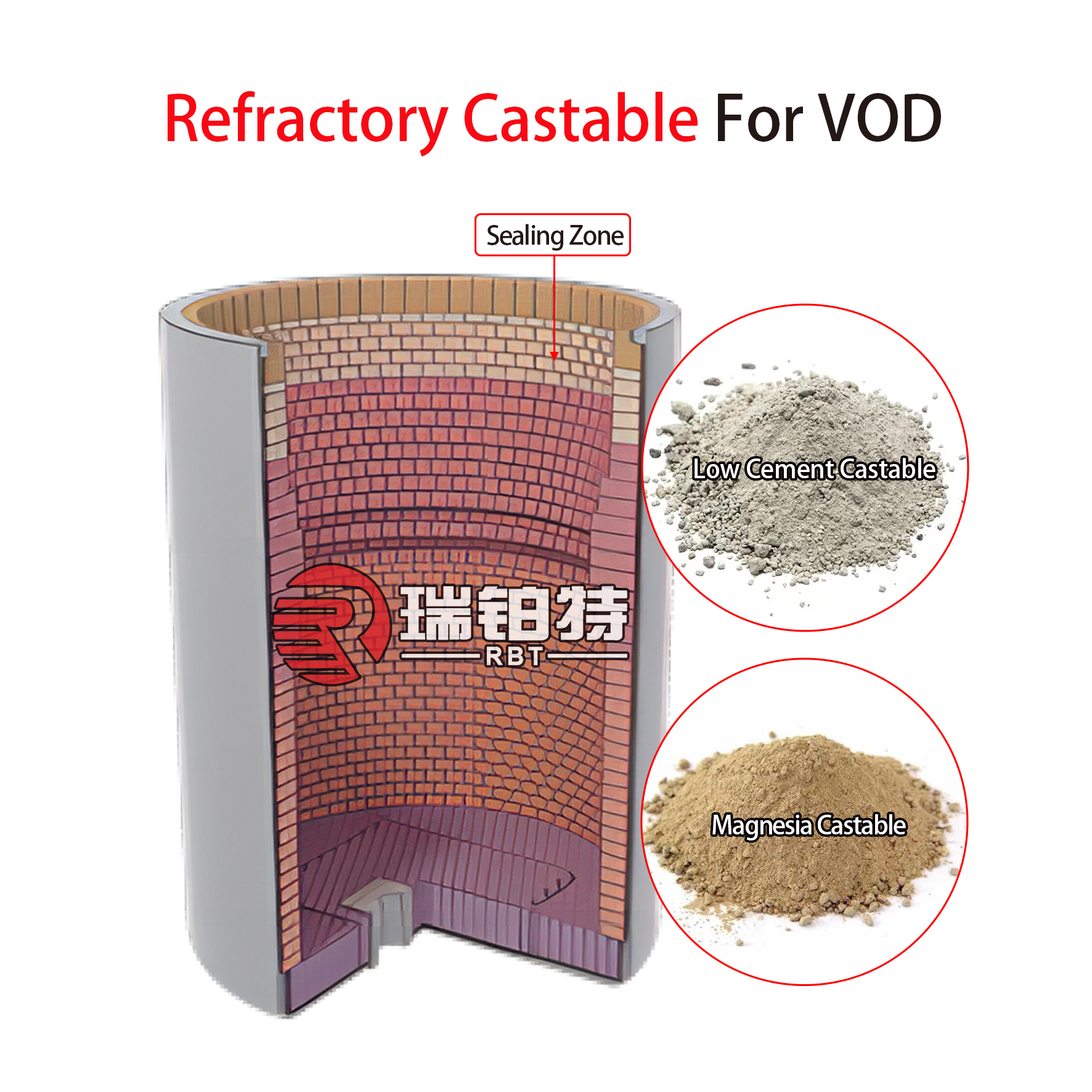

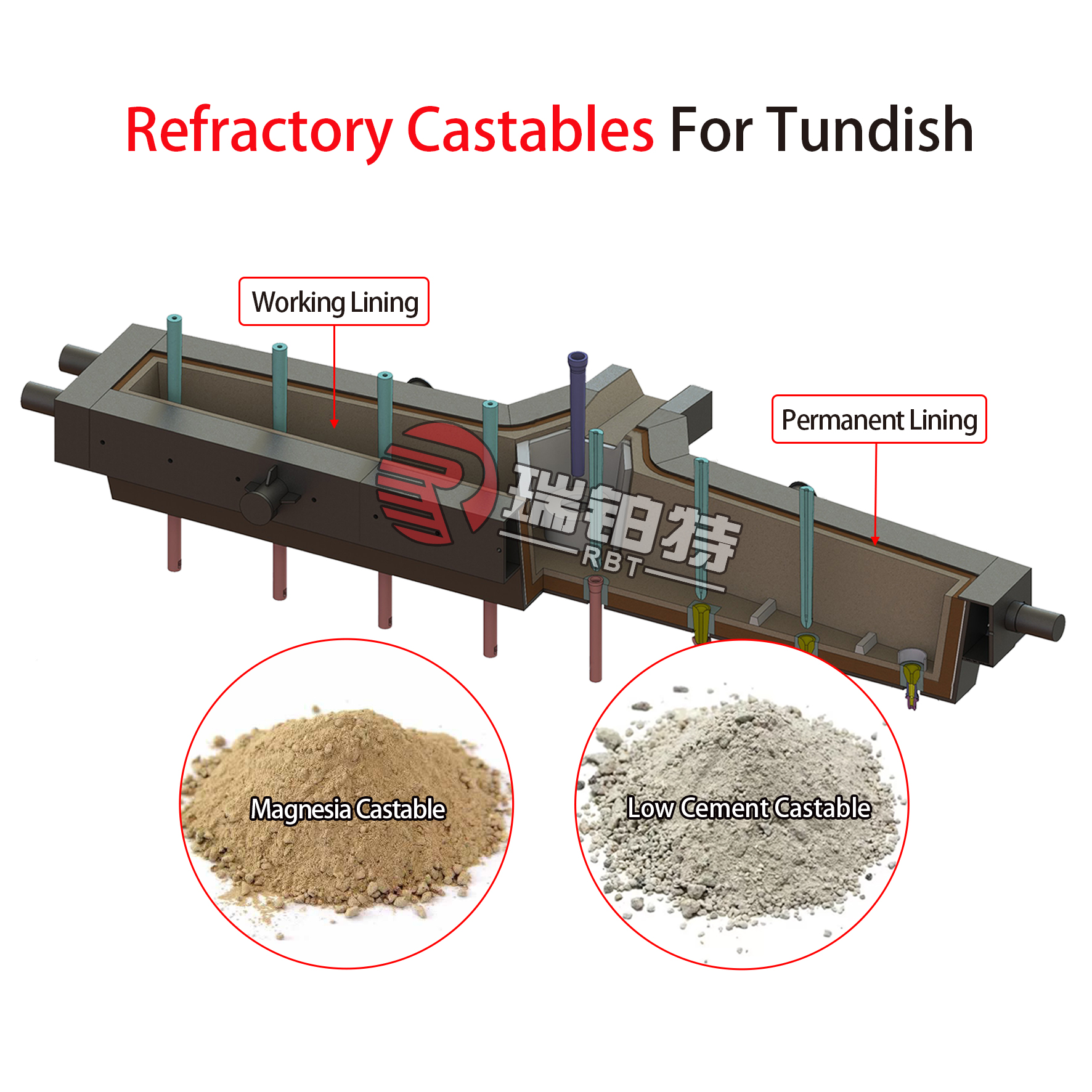

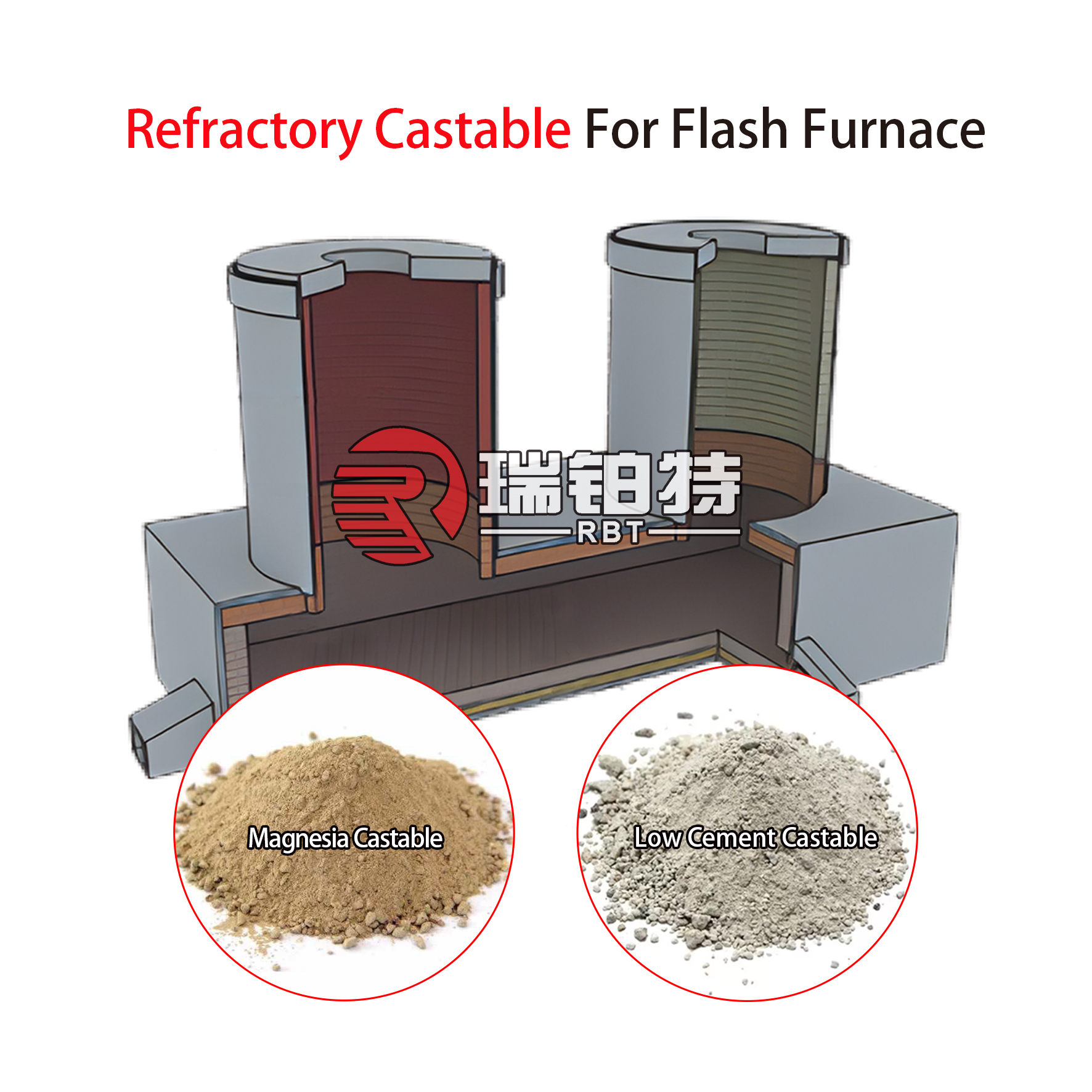

Isicelo

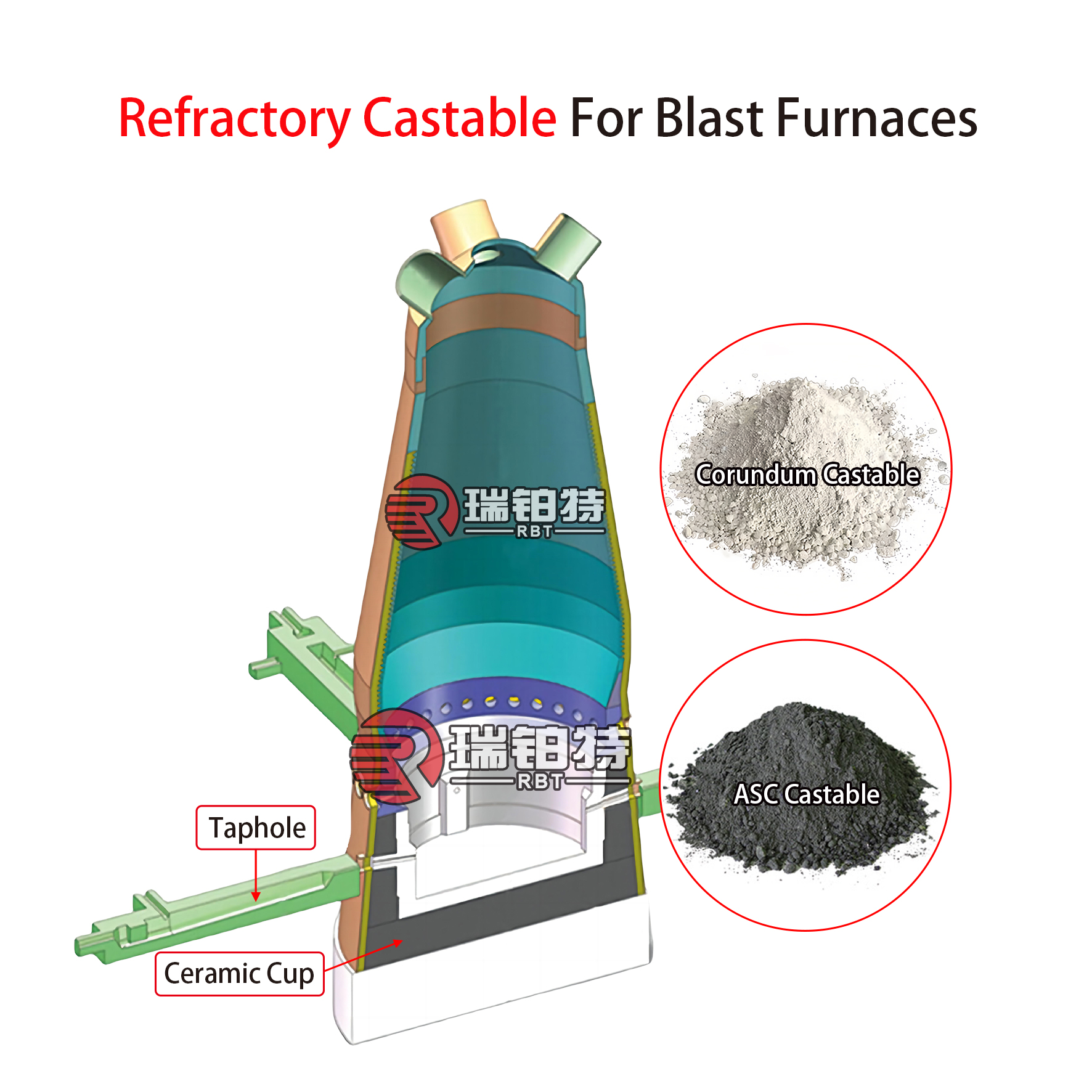

1. I-aluminium ephezulu enokuphoswa:I-castable ye-aluminium ephezulu yenziwe kakhulu yi-alumina (Al2O3) kwaye inokumelana okuphezulu, ukumelana nokutsha kwenkunkuma kunye nokumelana nobushushu. Isetyenziswa kakhulu kwii-ovens ezishushu kakhulu nakwiindawo zokufudumeza kwintsimbi, kwiintsimbi ezingezizo iintsimbi, kwiikhemikhali nakwamanye amashishini.

2. Ifayibha yentsimbi eqinisiweyo ephoswayo:I-castable yentsimbi eqinisiweyo isekelwe kwi-castables eziqhelekileyo kwaye i-fibers yentsimbi yongezwa ukomeleza ukumelana kwayo nobushushu, ukumelana nokuguguleka kunye nokumelana ne-slag. Isetyenziswa kakhulu kwii-oven, ezantsi kwi-oven nakwezinye iindawo kwi-steel, metallurgy, petrochemical kunye neminye imboni.

3. I-Mullite castable:I-Mullite castable yenziwe kakhulu yi-mullite (MgO·SiO2) kwaye inokumelana nokuguguleka okuhle, ukunganyangeki kakuhle kunye nokumelana nokulahlwa. Isetyenziswa kakhulu kwiindawo ezibalulekileyo ezifana nezitofu zokwenza intsimbi kunye neziguquli kwisinyithi, isinyithi kunye neminye imimandla.

4. I-silicon carbide enokuphoswa:I-silicon carbide castable yenziwe kakhulu yi-silicon carbide (SiC) kwaye inokumelana nokuguguleka okuhle kakhulu, ukumelana nokugqwala kunye nokumelana nokutshayiswa kobushushu. Isetyenziswa kakhulu kwii-oven ezishushu kakhulu, iibhedi ze-oven kunye nezinye iindawo zesinyithi ezingezizo i-ferrous, iikhemikhali, iiseramikhi kunye neminye imboni.

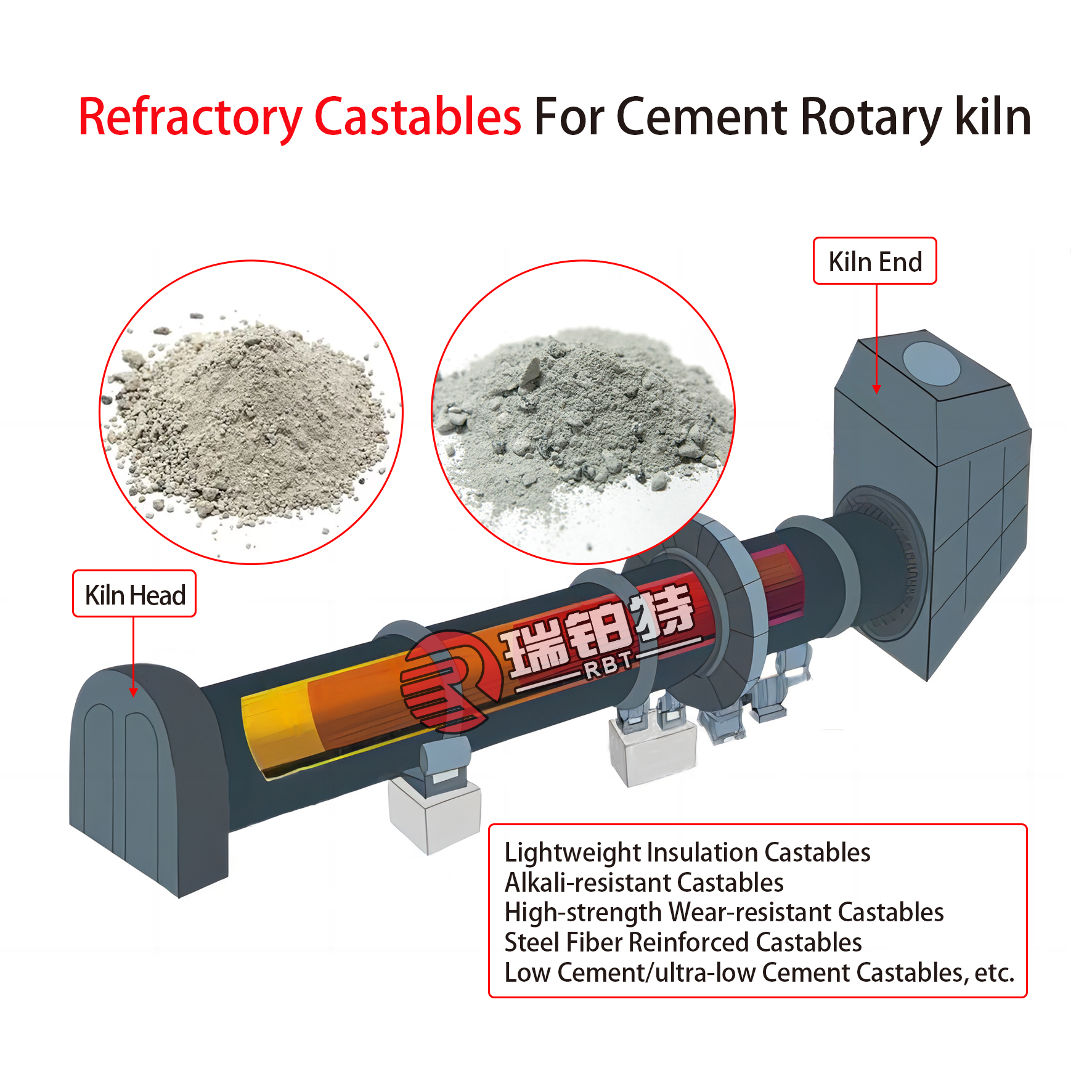

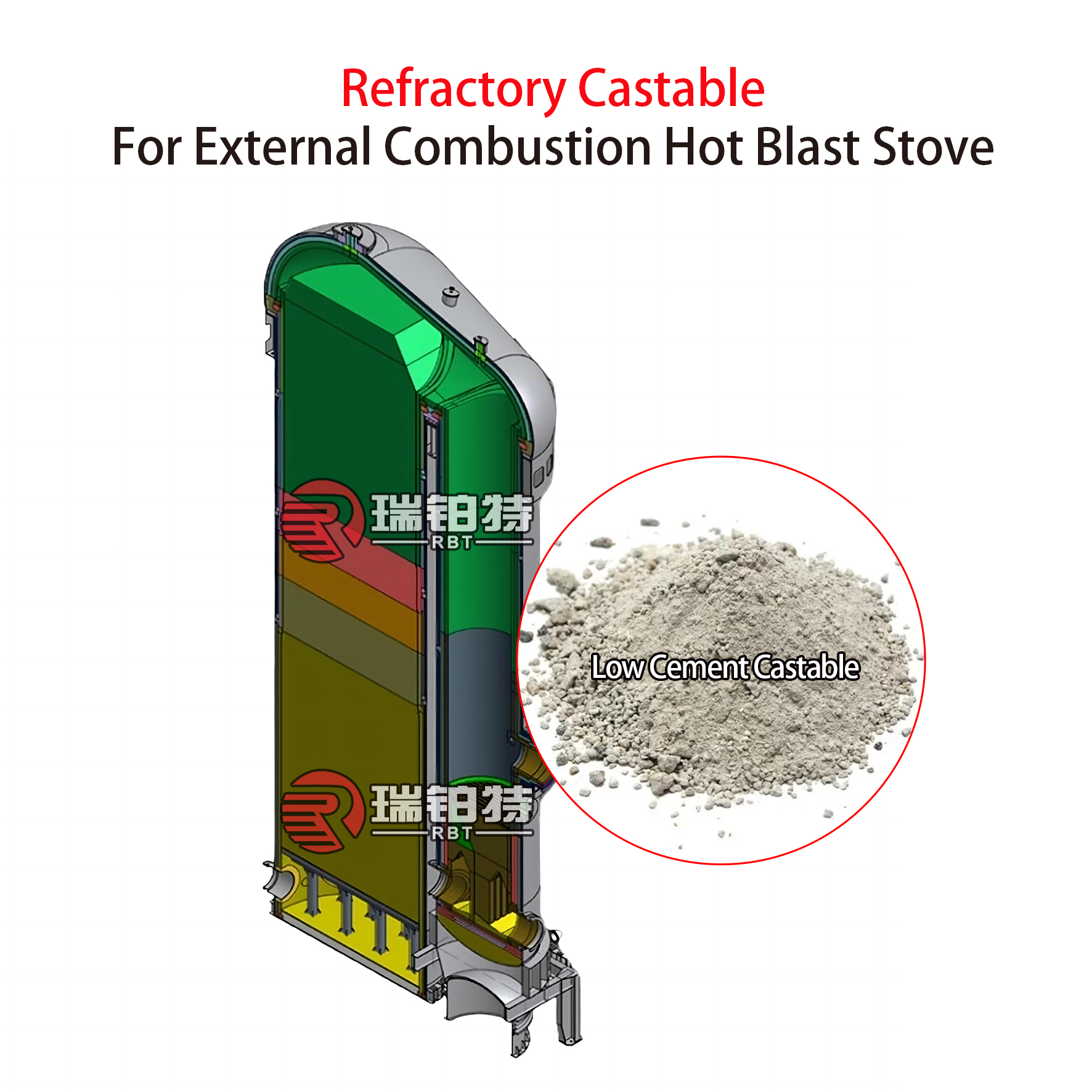

5. Izinto zokugquma ezinesamente encinci:Ibhekisa kwii-castables ezinomxholo ophantsi wesamente, oqhele ukuba malunga ne-5%, kwaye ezinye zincitshiswa ziye kwi-1% ukuya kwi-2%. Ii-castables ezinesamente ephantsi zisebenzisa amasuntswana amahle kakhulu angadluli kwi-1μm, kwaye ukumelana kwazo nobushushu, ukumelana ne-slag kunye nokumelana nokukhukuliseka kuphuculwe kakhulu. Ii-castables ezinesamente ephantsi zifanelekile kwii-linings zee-furniture ezahlukeneyo zonyango lobushushu, ii-furnitures zokufudumeza, ii-kilns ezithe nkqo, ii-kilns ezijikelezayo, ii-furniture covers zombane, imingxunya yokucofa i-furniture, njl.njl.; ii-castables ezinesamente ephantsi ezizihambelayo zifanelekile kwii-linings ze-spray gun ezidibeneyo ze-spray metallurgy, ii-linings ezimelana nokuguguleka kobushushu obuphezulu kwii-reactors ze-petrochemical catalytic cracking, kunye nee-linings zangaphandle zemibhobho yokupholisa amanzi e-furniture yokufudumeza.

6. Iikhasta ezinganyangekiyo ezinganyangekiyo:Izinto eziphambili zezixhobo ezixhathisa ukuguguleka ziquka izixhobo ezixhathisa ukuguguleka, iipowders, izongezo kunye nee-binders. Izixhobo ezixhathisa ukuguguleka ezixhathisa ukuguguleka luhlobo lwezinto ezixhathisa ukuguguleka ezisetyenziswa kakhulu kwi-metallurgy, ii-petrochemicals, izixhobo zokwakha, umbane kunye neminye imimandla. Ezi zinto zinezibonelelo zokuxhathisa ukuguguleka okuphezulu, ukuguguleka, kunye nokuguguleka. Zisetyenziselwa ukulungisa nokukhusela ulwelo lwezixhobo ezishushu kakhulu ezifana nee-ovens kunye nee-boilers ukwandisa ubomi benkonzo yezixhobo.

7. Ileyile enokuphoswa:I-ladle castable yi-castable engaphiliyo eyenziwe nge-clinker ye-alumina bauxite ekumgangatho ophezulu kunye ne-silicon carbide njengezinto eziphambili, ene-aluminate cement binder ecocekileyo, i-dispersant, i-arhente engatshiyo, i-coagulant, i-fiber engaqhumiyo kunye nezinye izongezo. Ngenxa yokuba inefuthe elihle kumaleko osebenzayo we-ladle, ikwabizwa ngokuba yi-aluminium silicon carbide castable.

8. Ikhaphukhaphu ekhaphukhaphu yokukhusela enganyangekiyo:I-castable ekhaphukhaphu ekhaphukhaphu ekhaphukhaphu yi-castable ekhaphukhaphu ekhaphukhaphu enobunzima obulula, amandla aphezulu kunye nokusebenza kakuhle kobushushu. Iquka ikakhulu ii-aggregates ezilula (ezifana ne-perlite, i-vermiculite, njl.njl.), izixhobo ezizinzileyo kubushushu obuphezulu, izihlanganisi kunye nezongezo. Isetyenziswa kakhulu kwizixhobo ezahlukeneyo zoshishino ezishushu kakhulu, ezifana nezitofu zoshishino, izitofu zonyango lobushushu, izitofu zentsimbi, izitofu zokunyibilikisa iglasi, njl.njl., ukuphucula ukusetyenziswa kwamandla kwezixhobo kunye nokunciphisa ukusetyenziswa kwamandla.

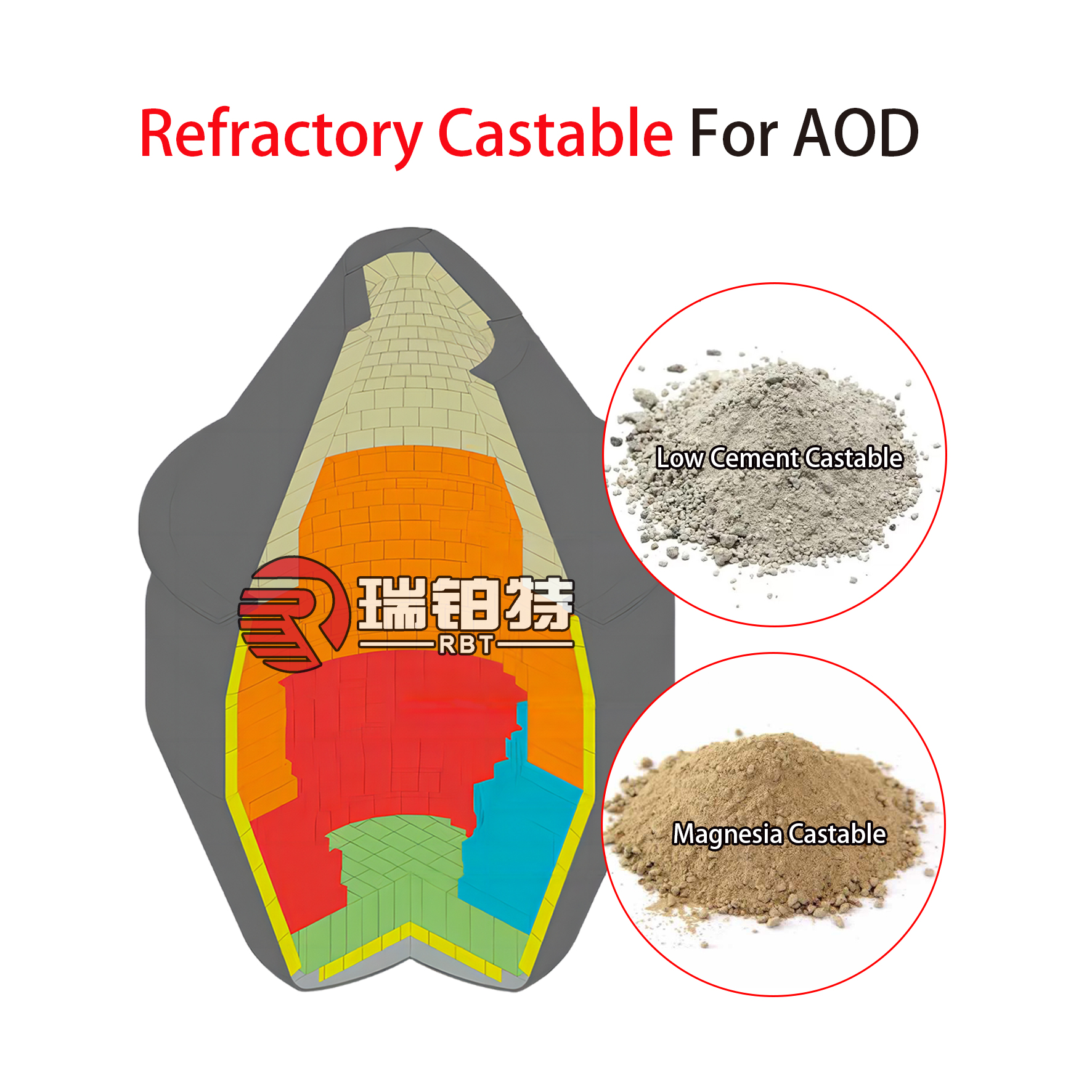

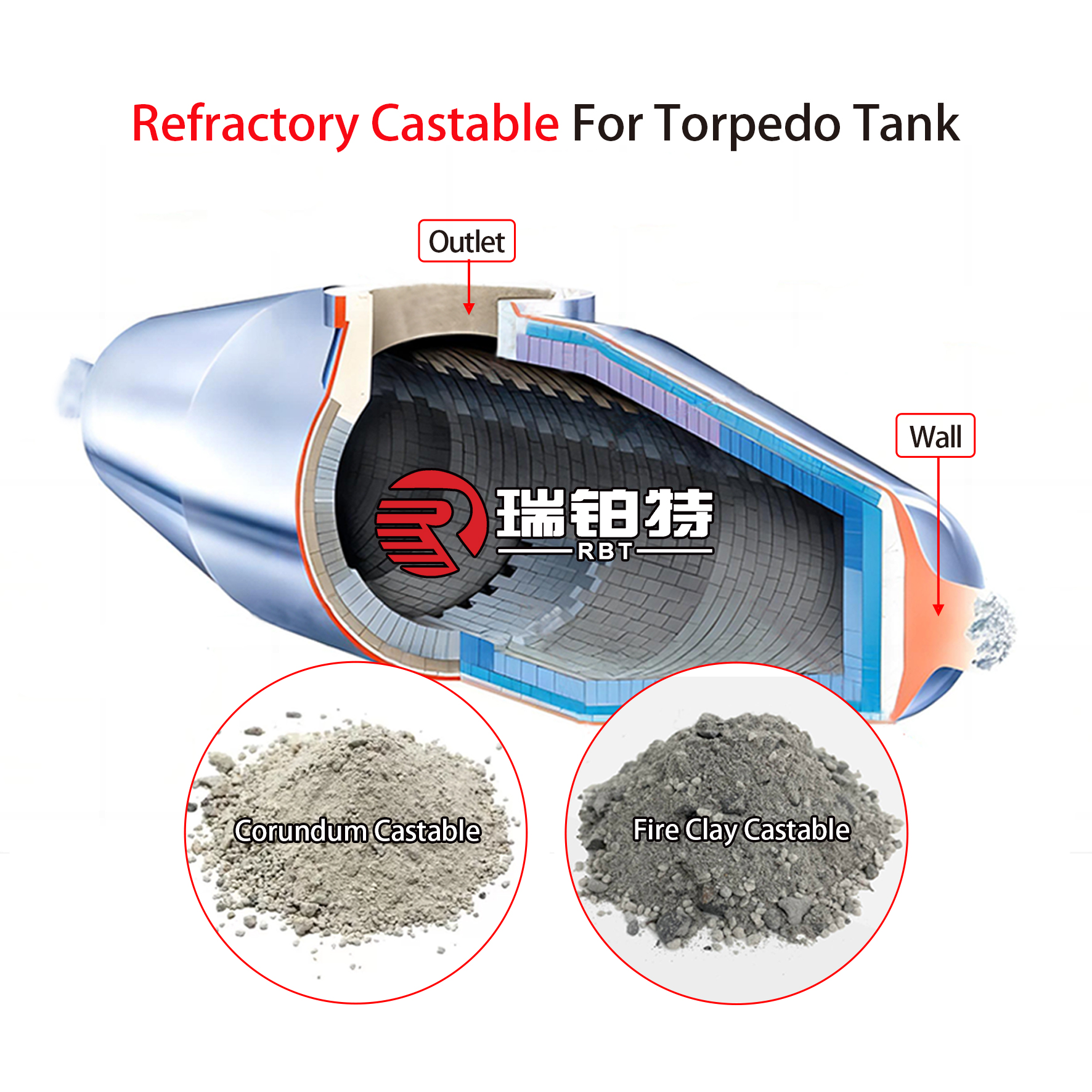

9. I-Corundum enokuphoswa:Ngenxa yokusebenza kwayo okugqwesileyo, i-corundum castable ibe lukhetho olufanelekileyo kwiindawo eziphambili zee-thermal oven. Iimpawu ze-corundum castable zinamandla aphezulu, ubushushu obuthambileyo bomthwalo ophezulu kunye nokumelana okuhle kwe-slag, njl. Ubushushu obuqhelekileyo buyi-1500-1800℃.

10. I-Magnesium enokuphoswa:Isetyenziswa kakhulu kwizixhobo zobushushu obuphezulu, inokumelana okuhle kakhulu nokugqwala kwe-alkaline slag, i-oxygen potential index ephantsi kwaye ayinangcoliseko kwintsimbi enyibilikisiweyo. Ke ngoko, inoluhlu olubanzi lwezinto ezingasetyenziswa kwishishini lesinyithi, ngakumbi kwimveliso yentsimbi ecocekileyo kunye neshishini lezinto zokwakha.

11. Udongwe olunokuphoswa:Izinto eziphambili yi-clay clinker kunye nodongwe oludibeneyo, oluzinzileyo kakuhle kubushushu kunye nokuchasana okuthile, kwaye ixabiso liphantsi kakhulu. Ihlala isetyenziswa kwi-lining yee-ovens zemizi-mveliso ngokubanzi, ezifana nee-heating furnaces, ii-annealing furnaces, ii-boilers, njl. Ingamelana nobushushu obuthile bomthwalo wobushushu kwaye idlala indima ekugqumeni ubushushu kunye nokukhusela umzimba we-furnace.

12. Izinto zokuphosa ezomileyo:Izinto ezisetyenziswa njenge-castable ezomileyo zenziwe ikakhulu zizinto ezingafunekiyo, ii-powders, ii-binders kunye namanzi. Izithako eziqhelekileyo ziquka i-clay clinker, i-tertiary alumina clinker, i-ultrafine powder, i-CA-50 cement, ii-dispersants kunye nee-siliceous okanye ii-feldspar immermeating agents.

Ii-castable ezomileyo zinokwahlulwa zibe ziintlobo ezininzi ngokwendlela ezisetyenziswa ngayo kunye nezithako zazo. Umzekelo, ii-castable ezomileyo ezingangeni manzi zisetyenziswa kakhulu kwiiseli ze-aluminium electrolytic, ezinokuthintela ngempumelelo ukungena kwee-electrolytes kwaye zandise ubomi benkonzo yeeseli. Ukongeza, ii-castable ezomileyo ezinganyangekiyo zifanelekile kwizixhobo zekhompyutha, ukunyibilikisa, ishishini leekhemikhali, iintsimbi ezingezizo iintsimbi kunye neminye imboni, ngakumbi kwishishini lesinyithi, njengomlomo we-kiln ejikelezayo, i-oven disintegration, i-oven head cover kunye nezinye iindawo.

Iprofayile yekhampani

I-Shandong Robert New Material Co., Ltd. ikwiSixeko saseZibo, kwiPhondo laseShandong, eTshayina, elisisiseko semveliso yezinto ezinganyangekiyo. Silishishini lanamhlanje elidibanisa uphando nophuhliso, imveliso, ukuthengisa, uyilo lwe-oven kunye nolwakhiwo, itekhnoloji, kunye nezixhobo ezinganyangekiyo ezithunyelwa kwamanye amazwe. Sinezixhobo ezipheleleyo, itekhnoloji ephucukileyo, amandla obuchwephesha aqinileyo, umgangatho wemveliso ogqwesileyo, kunye nodumo oluhle.Umzi-mveliso wethu ugubungela iihektare ezingaphezu kwama-200 kwaye imveliso yonyaka yezinto ezirhabaxa ezimile okwemilo imalunga neetoni ezingama-30000 kwaye izinto ezirhabaxa ezimile okwemilo zimalunga neetoni ezili-12000.

Iimveliso zethu eziphambili zezinto ezichasene ne-refractory ziquka:izixhobo zokuchasana ne-alkaline; izixhobo zokuchasana ne-silicon ye-aluminium; izixhobo zokuchasana ezingamiliyo; izixhobo zokuchasana ne-thermal insulation; izixhobo ezikhethekileyo zokuchasana ne-refractory; izixhobo zokuchasana ezisebenzayo kwiinkqubo zokuphosa eziqhubekayo.

Iimveliso zikaRobert zisetyenziswa kakhulu kwii-oven ezishushu kakhulu ezifana neentsimbi ezingenayo i-ferrous, intsimbi, izixhobo zokwakha kunye nolwakhiwo, iikhemikhali, amandla ombane, ukutshisa inkunkuma, kunye nonyango lwenkunkuma enobungozi. Zikwasetyenziswa kwiinkqubo zentsimbi kunye nesinyithi ezifana neeladle, i-EAF, ii-blast furnaces, ii-converters, ii-oven ze-coke, ii-hot blast furnaces; ii-oven ze-metallurgical ezingenayo i-ferrous ezifana nee-reverberators, ii-reduction furnaces, ii-blast furnaces, kunye nee-rotary furnaces; izixhobo zokwakha ii-oven zoshishino ezifana nee-glass furnaces, ii-cement furnaces, kunye nee-ceramic furnaces; ezinye ii-oven ezifana nee-boilers, ii-waste incinerators, i-roasting furnace, ezifumene iziphumo ezilungileyo ekusebenziseni. Iimveliso zethu zithunyelwa kwi-Southeast Asia, Central Asia, Middle East, Afrika, Europe, Americas nakwamanye amazwe, kwaye ziseke isiseko esihle sentsebenziswano namashishini amaninzi entsimbi aziwayo. Bonke abasebenzi bakaRobert bajonge phambili ngokunyanisekileyo ekusebenzeni nani kwimeko ephumelela kumacala omabini.

Imibuzo ebuzwa qho

Ngaba ufuna uncedo? Qiniseka ukuba undwendwela iiforam zethu zenkxaso ukuze ufumane iimpendulo kwimibuzo yakho!

Singumvelisi wokwenyani, umzi-mveliso wethu ugxile ekuveliseni izinto ezichasene nendalo kangangeminyaka engaphezu kwama-30. Sithembisa ukubonelela ngexabiso elifanelekileyo, eyona nkonzo ingcono ngaphambi kokuthengisa nasemva kokuthengisa.

Kwinkqubo nganye yemveliso, i-RBT inenkqubo epheleleyo ye-QC yokwakheka kweekhemikhali kunye neempawu zomzimba. Kwaye siza kuvavanya iimpahla, kwaye isatifikethi somgangatho siya kuthunyelwa kunye neempahla. Ukuba uneemfuno ezizodwa, siza kuzama konke okusemandleni ethu ukuzilungiselela.

Ngokuxhomekeke kubungakanani, ixesha lethu lokuhambisa lahlukile. Kodwa sithembisa ukuthumela ngokukhawuleza kangangoko kunokwenzeka ngomgangatho oqinisekisiweyo.

Kakade ke, sinikezela ngeesampuli zasimahla.

Ewe, ewe, wamkelekile ukutyelela inkampani ye-RBT kunye neemveliso zethu.

Akukho mda, singakunika ingcebiso nesisombululo esifanelekileyo ngokwemeko yakho.

Besisenza izinto ezirhabaxa kangangeminyaka engaphezu kwama-30, sinenkxaso yobugcisa enamandla kunye namava amaninzi, singanceda abathengi ukuba bayile ii-kiln ezahlukeneyo kwaye banikezele ngenkonzo enye.