I-mortar engabonakaliyo

Ulwazi lweMveliso

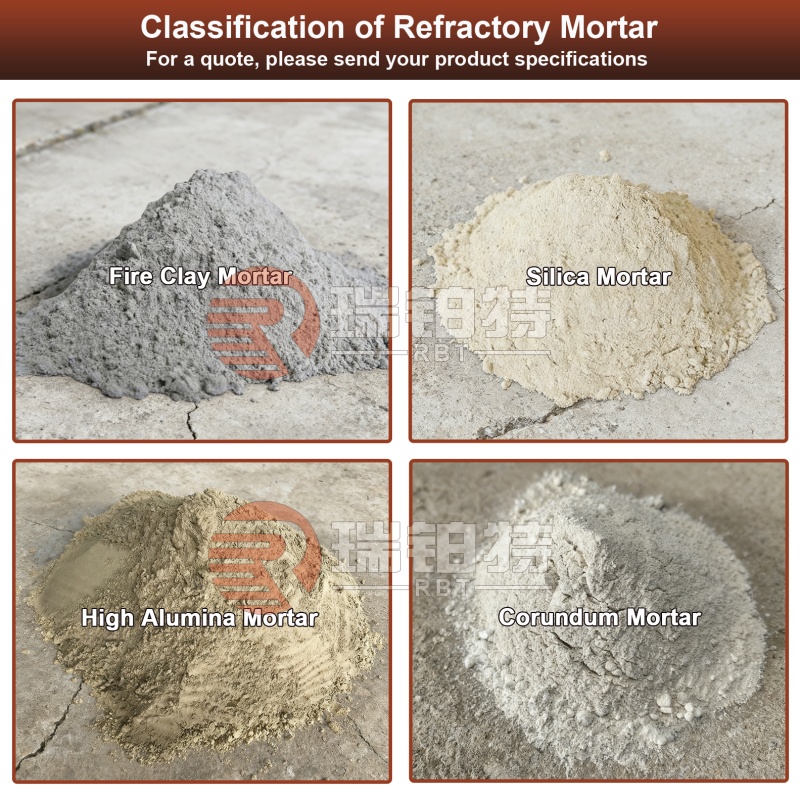

Udaka olurhabaxa,okwaziwa ngokuba yi-fire mortar okanye i-joint material (umgubo), esetyenziswa njengemveliso ye-bonding refractory, izixhobo ze-brickwork, ngokwezinto ezibonakalayo, zingahlulwa zibeudongwe, i-aluminium ephezulu, i-silicon kunye ne-magnesium refractory mortar, njl. njl.

Ibizwa ngokubaudaka oluqhelekileyo oluchasayoyenziwe ngomgubo we-clinker ongenakukhanyelwa kunye nodongwe lweplastiki njenge-binder kunye ne-ejenti yeplastiki. Amandla ayo kubushushu begumbi aphantsi, kwaye ukwakheka kwe-ceramic bonding kubushushu obuphezulu kunamandla aphezulu. Ngokusebenzisa i-hydraulicity, ukuqina komoya okanye izinto zokuqinisa ubushushu njenge-binder, ezibizwa ngokuba yi-udaka oluyi-refractory olubopha iikhemikhali, njengoko kungaphantsi kokwakheka kobushushu bokubopha be-ceramic ngaphambi kokuveliswa kwempendulo ethile yeekhemikhali kunye nokuqina.

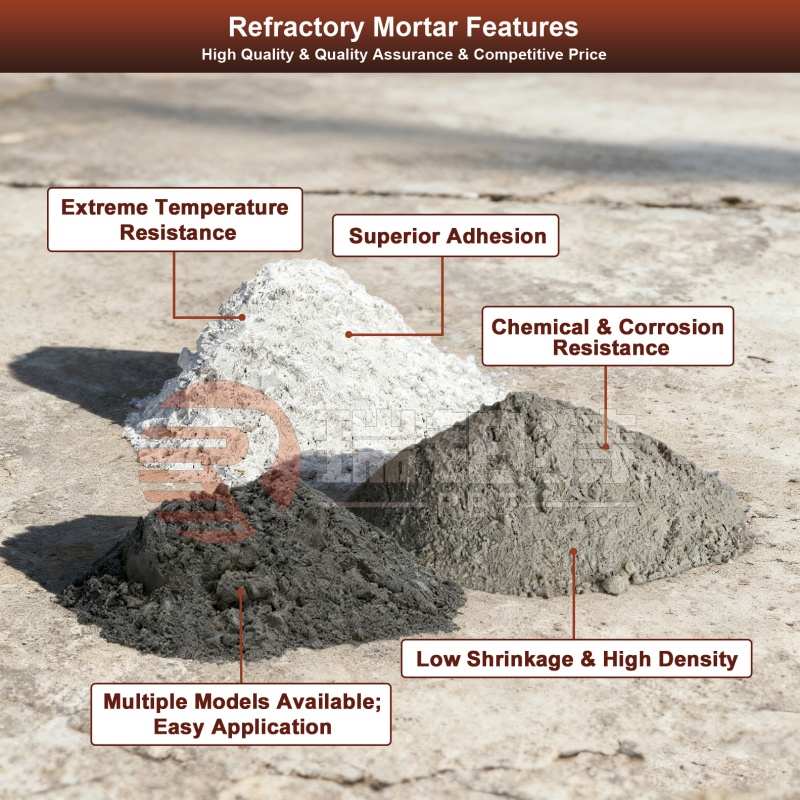

Iimpawu zedaka elirhabaxa:iplastiki elungileyo, ulwakhiwo olulula; amandla aphezulu okubopha, ukumelana nokugqwala okunamandla; ukuchasana okuphezulu, ukuya kuthi ga kwi-1650℃±50℃; ukumelana okuhle kokungena kwe-slag; ipropati elungileyo yokuchithwa kobushushu.

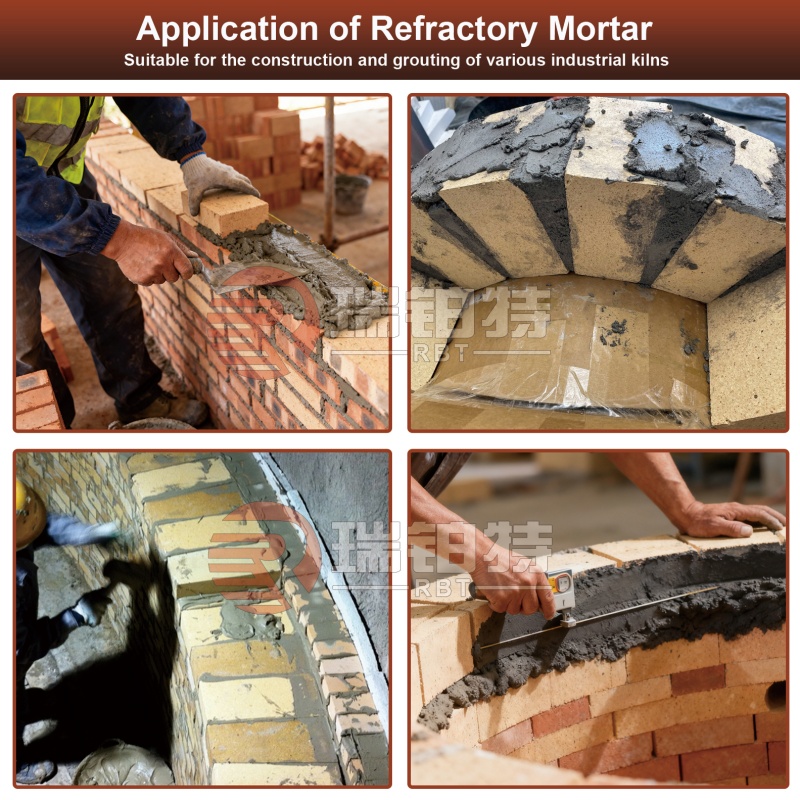

Udaka oluyi-refractory lusetyenziswa kakhulu kwi-oven ye-coke, kwi-oven yeglasi, kwi-oven ye-blast, kwi-hot blast stove, kwi-metallurgy, kwishishini lezinto zokwakha, koomatshini, kwi-petrochemical, kwi-glass, kwi-boiler, kumbane, kwi-iron nakwi-steel, kwi-samente nakwezinye ii-oven zoshishino.

Isalathiso seMveliso

| Isalathiso | Udongwe | I-Alumina ephezulu | ||||

| I-RBTMN-42 | I-RBTMN-45 | I-RBTMN-55 | I-RBTMN-65 | I-RBTMN-75 | ||

| IiRefractorines(℃) | 1700 | 1700 | 1720 | 1720 | 1750 | |

| I-CCS/MOR(MPa)≥ | 110℃×24h | 1.0 | 1.0 | 2.0 | 2.0 | 2.0 |

| 1400℃×3h | 3.0 | 3.0 | 4.0 | 4.0 | 4.0 | |

| Ixesha lokubopha (umzuzu) | 1~2 | 1~2 | 1~2 | 1~2 | 1~2 | |

| I-Al2O3(%) ≥ | 42 | 45 | 55 | 65 | 75 | |

| I-SiO2(%) ≥ | — | — | — | — | — | |

| I-MgO(%) ≥ | — | — | — | — | — | |

| Isalathiso | ICorundum | I-Silica | Ilula | ||

| I-RBTMN-85 | I-RBTMN-90 | I-RBTMN-90 | I-RBTMN-50 | ||

| IiRefractorines(℃) | 1800 | 1820 | 1670 | | |

| I-CCS/MOR(MPa)≥ | 110℃×24h | 2.0 | 2.0 | 1.0 | 0.5 |

| 1400℃×3h | 3.5 | 3.0 | 3.0 | 1.0 | |

| Ixesha lokubopha (umzuzu) | 1~3 | 1~3 | 1~2 | 1~2 | |

| I-Al2O3(%) ≥ | 85 | 90 | — | 50 | |

| I-SiO2(%) ≥ | — | — | 90 | — | |

| I-MgO(%) ≥ | — | — | — | — | |

| Isalathiso | I-Magnesia | |||

| I-RBTMN-92 | I-RBTMN-95 | I-RBTMN-95 | ||

| IiRefractorines(℃) | 1790 | 1790 | 1820 | |

| I-CCS/MOR(MPa)≥ | 110℃×24h | 1.0 | 1.0 | 1.0 |

| 1400℃×3h | 3.0 | 3.0 | 3.0 | |

| Ixesha lokubopha (umzuzu) | 1~3 | 1~3 | 1~3 | |

| I-Al2O3(%) ≥ | — | — | — | |

| I-SiO2(%) ≥ | — | — | — | |

| I-MgO(%) ≥ | 92 | 95 | 97 | |

1. I-mortar enokurhawuzelelwa eyenziwe ngodongwe

Izicelo eziPhambili:Ifanelekile ukubeka izitena ezirhabaxa ezisekelwe kudongwe kwiindawo ezinamaqondo obushushu aphantsi ≤1350℃, njengeendawo ezinamaqondo obushushu aphantsi kwii-oven zemizi-mveliso, iiflue, iitshimini, iindawo ezisezantsi zezitovu ezishushu ezivuselelayo, kunye nee-boiler linings—zonke zikwiindawo ezinamaqondo obushushu aphantsi, eziphakathi ukuya kweziphantsi.

Iimbonakalo:Ixabiso eliphantsi, ukusebenza kakuhle, ukumelana okuphakathi nokufudumeza nokupholisa ngokukhawuleza; ayifanelekanga kwiindawo ezinyibilikisiweyo ezishushu kakhulu/ezine-corrosion eninzi.

2. I-mortar ene-alumina ephezulu enganyangekiyo

Izicelo eziphambili:I-NM-50/NM-60: Ifanelekile kwizitena ze-alumina ephezulu (Al₂O₃ 55%~65%), ezisetyenziswa kwicandelo lobushushu obuphakathi kwii-kilns (1350~1500℃), njengee-kilns ze-ceramic, ii-furnance zokufudumeza ze-metallurgical, kunye neendawo zokutshintsha ze-kiln ye-rotary yesamente; I-NM-70/NM-75: Ifanelekile kwizitena ze-alumina ephezulu (Al₂O₃ ≥70%) okanye izitena ze-corundum, ezisetyenziswa kwicandelo lobushushu obuphezulu (1500~1700℃), ezifana nee-linings ze-blast furnace, ii-tapholes ze-steelmaking converter, ii-regenerators ze-kiln yeglasi, kunye nee-linings ze-calcium carbide furnace.

Iimbonakalo:Ukungaguquguquki okuphezulu, ukumelana nokungaguquki okuphezulu xa kuthelekiswa nokungaguquki okusekwe kudongwe; okukhona umxholo we-Al₂O₃ uphezulu, kokukhona ukumelana nobushushu obuphezulu kunye nokukhukuliseka komoya kunamandla.

3. I-Silica Refractory Mortar

Iindlela ezisetyenziswa kakhulu:Iyahambelana nezitena zesilika, ezenzelwe ngokukodwa iimeko ze-asidi ezifana nee-oven ze-coke, iindonga ze-oven zeglasi/iindonga zesifuba, kunye nezitofu zokwenza isinyithi ezine-asidi. Ubushushu bokusebenza bexesha elide: 1600~1700℃.

Iimbonakalo:Ayimelani nokukhukuliseka kwe-asidi ye-slag; iyahambelana kakuhle nokukhula kobushushu kunye nezitena ze-silica, kodwa ayimelani kakuhle ne-alkali; ayivumelekanga ngokungqongqo ukusetyenziswa kwii-alkaline oven.

4. I-Massica / Magnesium-chrome Refractory Mortar

Ukusetyenziswa Okuphambili: IMassica:Iyahambelana nezitena ze-magnesia; isetyenziswa kwiimeko ze-alkaline slag ezinamandla njengeziguquli ze-alkaline steelmaking, iintliziyo/iindonga ze-electric arc furnace, kunye nezitovu zokunyibilikisa isinyithi ezingenayo i-ferrous.

I-Magnesium-chrome:Iyahambelana nezitena ze-magnesia-chrome; isetyenziswa kwiimeko zokukhukuliseka kwe-alkaline ezishushu kakhulu ezifana neendawo zokutshisa i-oven yesamente, izixhobo zokutshisa inkunkuma, kunye nezitofu zokunyibilikisa isinyithi ezingenayo i-ferrous.

Iimbonakalo:Ukumelana okunamandla kakhulu ne-alkaline slag, kodwa ukumelana okuncinci nokufudumeza okukhawulezayo nokuphola; ukuthobela imiqathango yokusingqongileyo kuyafuneka kwi-magnesia-chrome refractory slurry (ezinye iindawo zithintela ukukhutshwa kwe-chromium ene-hexavalent).

5. Isinyithi esirhabaxa se-silicon carbide

Izicelo eziphambili:Ifanelekile kwizitena ze-silicon carbide/izitena ze-silicon carbide ezibotshelelwe yi-silicon nitride, ezisetyenziswa kwiindawo ezinobushushu obuphezulu, ezingagugiyo, nezinciphisa ubushushu ezifana nee-blast furnace tapping troughs, ii-ladle linings zentsimbi, ii-coking furnace riser pipes, kunye nee-secondary combustions of waste incinerators.

Iimbonakalo:Ukuqhuba okuphezulu kobushushu, ukumelana nokuguguleka okuphezulu, ukumelana nokuxinana kobushushu obuphezulu, kunye nobomi benkonzo obuphezulu kakhulu kuneemortars zodongwe/ze-alumina eziphezulu.

6. Udaka olungenasamente/olungenasamente

Izicelo eziphambili:Ifanelekile kwi-grouting/masonry yezinto ezisetyenziswa kwi-castables ezingenasamente okanye ezingenasamente okanye izitena ezibunjiweyo ezirhabaxa, isetyenziselwa ukudibanisa i-integral casting lining kwii-oven ezinkulu zoshishino kunye nokwakha ngokuchanekileyo kwee-ovens ezinobushushu obuphezulu (ezifana nee-ovens zeglasi kunye nee-ovens zombane ze-metallurgical), ezinobushushu obusebenzayo obuyi-1400~1800℃.

Iimbonakalo:Umthamo wamanzi uphantsi, uxinano oluphezulu kunye namandla emva kokusila, akukho ngxaki yokwandiswa komthamo obangelwa kukufuma kwesamente, kunye nokumelana nokukhukuliseka okugqwesileyo.

Iprofayile yekhampani

I-Shandong Robert New Material Co., Ltd.ikwiSixeko saseZibo, kwiPhondo laseShandong, eTshayina, elisisiseko semveliso yezinto ezinganyangekiyo. Silishishini lanamhlanje elidibanisa uphando nophuhliso, imveliso, ukuthengisa, uyilo lwe-oven kunye nolwakhiwo, iteknoloji, kunye nezixhobo ezinganyangekiyo ezithunyelwa kwamanye amazwe. Sinezixhobo ezipheleleyo, iteknoloji ephucukileyo, amandla obuchwephesha aqinileyo, umgangatho wemveliso ogqwesileyo, kunye nodumo oluhle. Umzi-mveliso wethu ugubungela iihektare ezingaphezu kwama-200 kwaye imveliso yonyaka yezixhobo ezinganyangekiyo ezimile imalunga neetoni ezingama-30000 kwaye izinto ezinganyangekiyo ezimile ziitoni ezili-12000.

Iimveliso zethu eziphambili zezinto ezichasene ne-refractory ziquka:izixhobo zokuchasana ne-alkaline; izixhobo zokuchasana ne-silicon ye-aluminium; izixhobo zokuchasana ezingamiliyo; izixhobo zokuchasana ne-thermal insulation; izixhobo ezikhethekileyo zokuchasana ne-refractory; izixhobo zokuchasana ezisebenzayo kwiinkqubo zokuphosa eziqhubekayo.

Imibuzo ebuzwa qho

Ngaba ufuna uncedo? Qiniseka ukuba undwendwela iiforam zethu zenkxaso ukuze ufumane iimpendulo kwimibuzo yakho!

Singumvelisi wokwenyani, umzi-mveliso wethu ugxile ekuveliseni izinto ezichasene nendalo kangangeminyaka engaphezu kwama-30. Sithembisa ukubonelela ngexabiso elifanelekileyo, eyona nkonzo ingcono ngaphambi kokuthengisa nasemva kokuthengisa.

Kwinkqubo nganye yemveliso, i-RBT inenkqubo epheleleyo ye-QC yokwakheka kweekhemikhali kunye neempawu zomzimba. Kwaye siza kuvavanya iimpahla, kwaye isatifikethi somgangatho siya kuthunyelwa kunye neempahla. Ukuba uneemfuno ezizodwa, siza kuzama konke okusemandleni ethu ukuzilungiselela.

Ngokuxhomekeke kubungakanani, ixesha lethu lokuhambisa lahlukile. Kodwa sithembisa ukuthumela ngokukhawuleza kangangoko kunokwenzeka ngomgangatho oqinisekisiweyo.

Kakade ke, sinikezela ngeesampuli zasimahla.

Ewe, ewe, wamkelekile ukutyelela inkampani ye-RBT kunye neemveliso zethu.

Akukho mda, singakunika ingcebiso nesisombululo esifanelekileyo ngokwemeko yakho.

Besisenza izinto ezirhabaxa kangangeminyaka engaphezu kwama-30, sinenkxaso yobugcisa enamandla kunye namava amaninzi, singanceda abathengi ukuba bayile ii-kiln ezahlukeneyo kwaye banikezele ngenkonzo enye.