Ityhubhu yoKhuselo lwe-RSiC

Ulwazi lweMveliso

Iityhubhu zoKhuseleko lweCarbide yeSiliconziinxalenye ezikhethekileyo zetyhubhu ezenziwe ngezinto zeseramikhi zesilicon carbide (SiC), ezisetyenziswa kakhulu ukukhusela izinto ezinobuthathaka (ezifana ne-thermocouples) okanye njengeenxalenye eziphambili kwizixhobo zothutho lolwelo olushushu kakhulu kunye nezixhobo zokutshintshiselana nobushushu.

Iimveliso zethu zenziwa ikakhulu kusetyenziswa iinkqubo ezintathu:Ukunyibilikisa i-reaction (RBSiC), i-Recrystallization (RSiC), i-silicon carbide ebotshelelweyo ye-silicon nitride (NSiC)

1. Iityhubhu zokukhusela i-RSiC

Isebenzisa umgubo omncinci we-SiC ococekileyo kakhulu njengezinto eziluhlaza, itshiswa kubushushu obuphezulu (2000–2200℃). Isakhiwo esixineneyo senziwa ngokudityaniswa kwakhona kunye nokuhlanganiswa kwemida yeenkozo zee-SiC ngokwazo, ngaphandle kwesigaba esongezelelweyo sokubopha.

Iimpawu eziphambili:

Ukumelana Okungaqhelekanga Nobushushu Obuphezulu:Ubushushu bokusebenza obuhlala ixesha elide ukuya kuthi ga kwi-1600℃, ukumelana kwexesha elifutshane ukuya kwi-1800℃, okwenza ukuba ibe yeyona ilungileyo ngokubhekiselele ekumelaneni nobushushu obuphezulu phakathi kweentlobo ezintathu, ezifanelekileyo kwii-ovens ezishushu kakhulu (ezifana nee-ovens ze-ceramic sintering kunye nee-ovens ze-metallurgical blast).

Ukumelana kakuhle kwe-Oxidation:Kumaqondo obushushu aphezulu, ifilimu ekhuselayo yeSiO₂ eninzi iyakheka phezu komphezulu, ithintela ukuxinana okungakumbi kweSiC yangaphakathi, ibonise uzinzo oluphezulu kakhulu kwimozulu exoxisayo.

Umlinganiselo ophantsi kakhulu wokwandiswa kobushushu:I-coefficient yokwandiswa kobushushu yi-4.5 × 10⁻⁶ /℃ kuphela, enika ukumelana okuhle kobushushu, nangona iphantsi kancinci kune-silicon carbide ebotshelelwe yi-silicon nitride.

Ubulukhuni obuphezulu kunye nokumelana nokuguguleka okuphezulu:Njengoko i-Mohs ilukhuni phantse kwi-9, ibonakalisa ukumelana okubalaseleyo nokukhukuliseka kwezinto kunye nokukrala, okwenza ukuba ifaneleke ukuhamba komoya obushushu obuphezulu kunye nokuhamba kolwelo okuqulethe amasuntswana aqinileyo.

Uzinzo oluqinileyo lweekhemikhali:Ayimelani nee-asidi ezinamandla kunye nee-alkali, kwaye ayisebenzi kwiintsimbi ezininzi ezinyibilikisiweyo.

Imida:

Ubushushu obuphezulu kakhulu bokugqwala, okubangela ukubola okuphezulu kancinci (malunga ne-5%–8%) kunye nokumelana noxinzelelo oluphezulu okubuthathaka kancinci; ukubuthathaka okuphezulu kobushushu begumbi, kunye nokumelana nempembelelo akulunganga njenge-silicon carbide ebotshelelwe yi-silicon nitride.

2. Iityhubhu zokukhusela i-RBSiC

Ngokusebenzisa amasuntswana eSiC kunye negraphite njengezinto eziluhlaza, le nto ingena kwinkqubo yokungena kwesilicon. I-silicon engamanzi ingena ize izalise iimbobo, isabela negraphite ukuze yenze isigaba esitsha seSiC, ekugqibeleni idale isakhiwo esidibeneyo se "SiC framework + free silicon".

Iimpawu eziphambili:

Uxinano oluphezulu kunye ne-porosity ephantsi:I-silicon yasimahla izalisa iimbobo, inciphisa iimbobo zibe ngaphantsi kwe-1%, nto leyo ebangela ukuba umoya ungangeni kakuhle kwaye ikwazi ukumelana noxinzelelo oluphezulu, ifaneleke kuxinzelelo oluphezulu kunye nobushushu obuphezulu.

iimeko zokutywina (ezifana nezitofu zokufunxa uxinzelelo).

Iimpawu ezilungileyo zoomatshini:Amandla okugoba obushushu begumbi angama-250–400MPa, ukomelela okukhulu kokuqhekeka, kunye nokumelana nempembelelo okungaphezulu kune-silicon carbide ephinde yasetyenziswa.

Ukumelana okuphakathi kobushushu obuphezulu:Ubushushu bokusebenza bexesha elide yi-1200℃. Ngaphezulu kwe-1350℃, i-silicon ekhululekileyo iyathamba, nto leyo ekhokelela ekwehleni kwamandla kunye nokunciphisa ukusebenza kobushushu obuphezulu.

Ukusebenziseka kakuhle:Ukubakho kwe-silicon ekhululekileyo kunciphisa ukuqhekeka kwezinto, okwenza kube lula ukuzisebenzisa zibe ziimo ezintsonkothileyo, nto leyo ebangela iindleko zemveliso eziphantsi kakhulu.

Imida:

Ukusebenza kobushushu obuphezulu kuthintelwe yi-silicon ekhululekileyo, nto leyo eyenza ukuba ingafaneleki ukusebenza ixesha elide ngaphezu kwe-1350℃; i-silicon ekhululekileyo isabela ngokulula kwi-alkalis enamandla, i-aluminium enyibilikisiweyo, njl.njl., nto leyo ekhokelela kuluhlu oluncinci lokumelana nokugqwala.

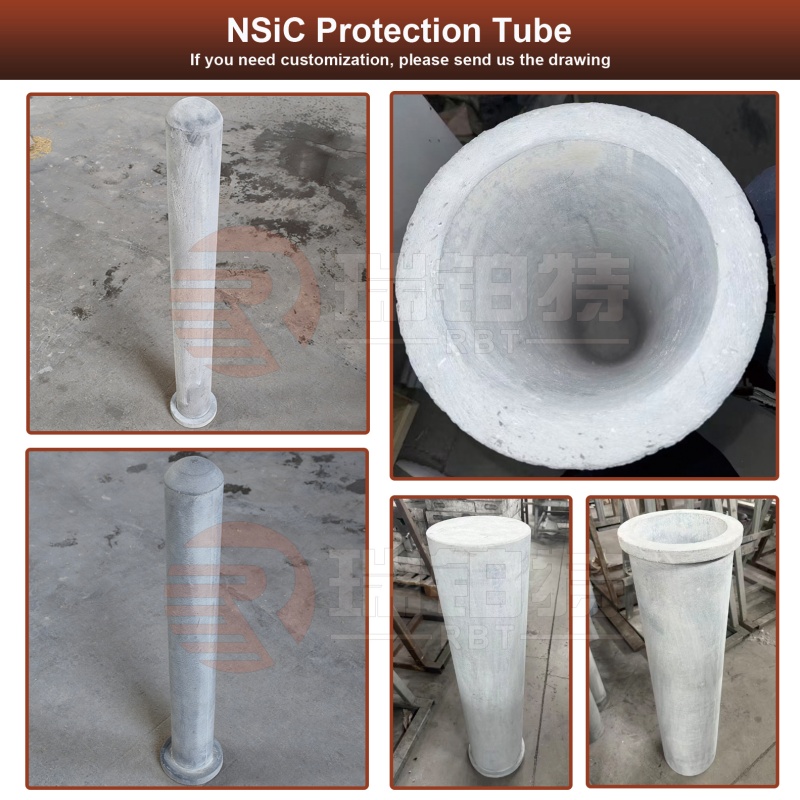

3. Ityhubhu yokukhusela i-NSiSC

Yinto edityanisiweyo eyenziwe ngokuqhagamshela amasuntswana eSiC ngokuqinileyo kwi-silicon carbide matrix ngokuvelisa iSi₃N₄ njengesigaba sokubopha nge-nitriding reaction.

Ezona mpawu:

1. Ukumelana nobushushu obuphezulu kakhulu:I-coefficient ephantsi yokwandiswa kobushushu kunye nokuqina okuphezulu kwesigaba esidibeneyo seSi₃N₄ kuvumela ityhubhu yokukhusela ukuba imelane nokufudumeza okukhawulezayo kunye nokuphola okungaphezulu kwe-1000℃ ngaphandle kokuqhekeka ngenxa yotshintsho olukhawulezileyo lobushushu, okwenza ukuba ifaneleke kwiimeko zokusebenza kunye nokuguquguquka rhoqo kobushushu.

2. Ukumelana nokugqwala okugqwesileyo:Izinzile kakhulu kwii-asidi ezinamandla, ii-alkalis ezinamandla, iintsimbi ezinyibilikisiweyo (ezifana ne-aluminium kunye nobhedu), kunye neetyuwa ezinyibilikisiweyo, nto leyo eyenza ukuba ifaneleke ngakumbi kwiindawo ezirhabaxa kwimizi-mveliso yeekhemikhali kunye ne-metallurgical.

3. Amandla aphezulu oomatshini:Amandla okuguquguquka kobushushu begumbi afikelela kwi-300–500 MPa, kunye nokugcinwa kwamandla okungcono kumaqondo obushushu aphezulu kuneemveliso zeSiC ezicocekileyo, kunye nokumelana okunamandla kwempembelelo.

4. Ubushushu bokusebenza:Ubushushu bokusebenza bexesha elide yi-1350℃, amandla okumelana nexesha elifutshane ukuya kuthi ga kwi-1500℃.

5. Ukhuseleko Olulungileyo:Igcina ubushushu obuhle bombane nokuba kubushushu obuphezulu, ithintela ukuphazamiseka kwesignali ye-thermocouple.

Imida:

Ukumelana ne-oxidation kungaphantsi kancinci kune-silicon carbide ephinde yasetyenziswa; ukusetyenziswa ixesha elide kwiindawo ezinamandla ze-oxidation kunokukhokelela ekuqhekekeni kongqimba lwe-oxide kumphezulu.

Itheyibhile yokuthelekisa iimpawu eziphambili

| Uphawu | I-Si₃N₄-SiC | R-SiC | RB-SiC |

| Ubushushu bokusebenza bexesha elide | 1350℃ | 1600℃ | 1200℃ |

| Ukumelana noTshabalalo oluTshisayo | Eyona ifanelekileyo | Kulungile | Phakathi |

| Iipropati ze-Antioxidant | Kulungile | Eyona ifanelekileyo | Phakathi |

| Ukumelana nokugqwala | Iqinile (imelana nee-asidi kunye ne-alkalis / isinyithi esinyibilikisiweyo) | Iqinile (imelana ne-oxidation kunye nokugqwala) | Phakathi (Ziphephe ii-alkalis ezinamandla/i-aluminium enyibilikisiweyo) |

| Ukugquma | 3%–5% | 5%–8% | <1% |

| Ukumelana neempembelelo | Unamandla | Ubuthathaka | Phakathi |

Amashishini aqhelekileyo kunye neemeko

1. I-tube ye-NSiC yokukhusela i-thermocouple

Ushishino lweeKhemikhali:Ukulinganiswa kobushushu kwimithambo ye-acid-base reaction vessels, iiseli ze-electrolytic zetyuwa enyibilikisiweyo, kunye neetanki zokugcina izinto ezibolayo; imelana nokugqwala kwexesha elide okuvela kwii-asidi ezinamandla, ii-alkalis, kunye neetyuwa ezinyibilikisiweyo; ifanelekile kwiimeko zokusabela ezingaqhelekanga kunye nokuguquguquka rhoqo kobushushu.

Ushishino lweMetallurgical:Ukulinganiswa kobushushu besinyithi esinyibilikisiweyo kwiimolds ze-aluminium die-casting, ii-furnitures ze-copper smelting, kunye nee-furnitures zesinyithi ezingeyo-ferrous; ezimelana nokukhukuliseka kwesinyithi esinyibilikisiweyo, kwaye ubushushu bayo obuphezulu buthintela ukuphazamiseka kwesignali ye-thermocouple.

Ushishino lweZixhobo zokwakha:Ukulinganiswa kobushushu kwii-oven ze-lime ezihlala zihleli kunye nee-oven ze-gypsum calcining; ezikwaziyo ukumelana nokufudumeza nokupholisa ngokukhawuleza okubangelwa kukuqala nokuvala kwe-oven; ezimelana nokugqwala okuvela kwi-alkaline flue gas ngaphakathi kwi-oven.

2. Iityhubhu zoKhuseleko lwe-RSiC Thermocouple

Ushishino lweZixhobo zokwakha:Ukulinganiswa kobushushu kwiindawo zokutshisa i-oven yesamente ejikelezayo, ii-oven ze-ceramic roller, kunye nee-oven ze-tunnel ze-refractory material; imelana nobushushu obuphezulu kakhulu be-1600℃ kunye nokukhukuliseka okunamandla okuvela kwiipowders zobushushu obuphezulu, ezifanelekileyo kwiimeko zemveliso eziqhubekayo zobushushu obuphezulu.

Ushishino lweMetallurgical:Ukulinganiswa kobushushu kwiipayipi zokuqhuma ezishushu ze-blast furnace, iiladle zentsimbi enyibilikisiweyo, kunye nezixhobo zokulungisa isinyithi esinyibilikisiweyo; zingasetyenziswa ixesha elide kwiindawo ezinamandla okukhupha i-oxidizing, zimelana nokugqwala okuvela kwigesi yokukhupha ubushushu obuphezulu kunye ne-iron slag.

Ishishini leglasi:Ukulinganiswa kobushushu kwizixhobo zokuhlaziya iziko lokunyibilikisa iglasi kunye neenkuni ezenza iglasi; imelana nokugqwala kunye nokukhukuliseka kobushushu obuphezulu okuvela kwiglasi enyibilikisiweyo, ihlangabezana neemfuno eziqhubekayo zobushushu obuphezulu bokuveliswa kweglasi.

3. Iityhubhu zoKhuseleko lweThermocouple zeRBSiC

Ushishino Lokuvelisa Oomatshini:Ukulinganiswa kobushushu kwii-oven zonyango lobushushu, kwii-oven zokucima umlilo ngegesi, nakwii-oven ze-carburizing; zifanelekile kwiimeko zobushushu eziphakathi nezisezantsi ezizinzileyo, kwaye zinokumelana nokukhukuliseka okuncinci kwee-particles ezikwi-furnace.

Ishishini laMandla:Ukulinganisa ubushushu kwiibhoyila zoxinzelelo lomoya, izitovu ezishushu, kunye nezixhobo zokubuyisa ubushushu obumdaka; zifanelekile kwiindawo ezingathathi cala okanye ezibuthathaka, ezihlangabezana neemfuno zokulinganisa ubushushu obuvaliweyo ukusuka kuxinzelelo oluphantsi ukuya koluphakathi ukuya koluphezulu.

Izixhobo zovavanyo:Ukulinganiswa kobushushu kwiifeni ezincinci ezitshisayo ezinoxinzelelo oluphezulu kunye neefeni ezityhubhu zelebhu; ukungakwazi kwayo ukungena komoya okuphantsi kwenza ukuba ifaneleke kwiindawo ezincinci nezivaliweyo zovavanyo ezinoxinzelelo oluphezulu.

I-Metallurgical

Ikhemikhali

Amandla

Inqwelo-moya

I-elektroniki

Ii-Roller Kilns

Iprofayile yekhampani

I-Shandong Robert New Material Co., Ltd.ikwiSixeko saseZibo, kwiPhondo laseShandong, eTshayina, elisisiseko semveliso yezinto ezinganyangekiyo. Silishishini lanamhlanje elidibanisa uphando nophuhliso, imveliso, ukuthengisa, uyilo lwe-oven kunye nolwakhiwo, iteknoloji, kunye nezixhobo ezinganyangekiyo ezithunyelwa kwamanye amazwe. Sinezixhobo ezipheleleyo, iteknoloji ephucukileyo, amandla obuchwephesha aqinileyo, umgangatho wemveliso ogqwesileyo, kunye nodumo oluhle. Umzi-mveliso wethu ugubungela iihektare ezingaphezu kwama-200 kwaye imveliso yonyaka yezixhobo ezinganyangekiyo ezimile imalunga neetoni ezingama-30000 kwaye izinto ezinganyangekiyo ezimile ziitoni ezili-12000.

Iimveliso zethu eziphambili zezinto ezichasene ne-refractory ziquka:izixhobo zokuchasana ne-alkaline; izixhobo zokuchasana ne-silicon ye-aluminium; izixhobo zokuchasana ezingamiliyo; izixhobo zokuchasana ne-thermal insulation; izixhobo ezikhethekileyo zokuchasana ne-refractory; izixhobo zokuchasana ezisebenzayo kwiinkqubo zokuphosa eziqhubekayo.

Imibuzo ebuzwa qho

Ngaba ufuna uncedo? Qiniseka ukuba undwendwela iiforam zethu zenkxaso ukuze ufumane iimpendulo kwimibuzo yakho!

Singumvelisi wokwenyani, umzi-mveliso wethu ugxile ekuveliseni izinto ezichasene nendalo kangangeminyaka engaphezu kwama-30. Sithembisa ukubonelela ngexabiso elifanelekileyo, eyona nkonzo ingcono ngaphambi kokuthengisa nasemva kokuthengisa.

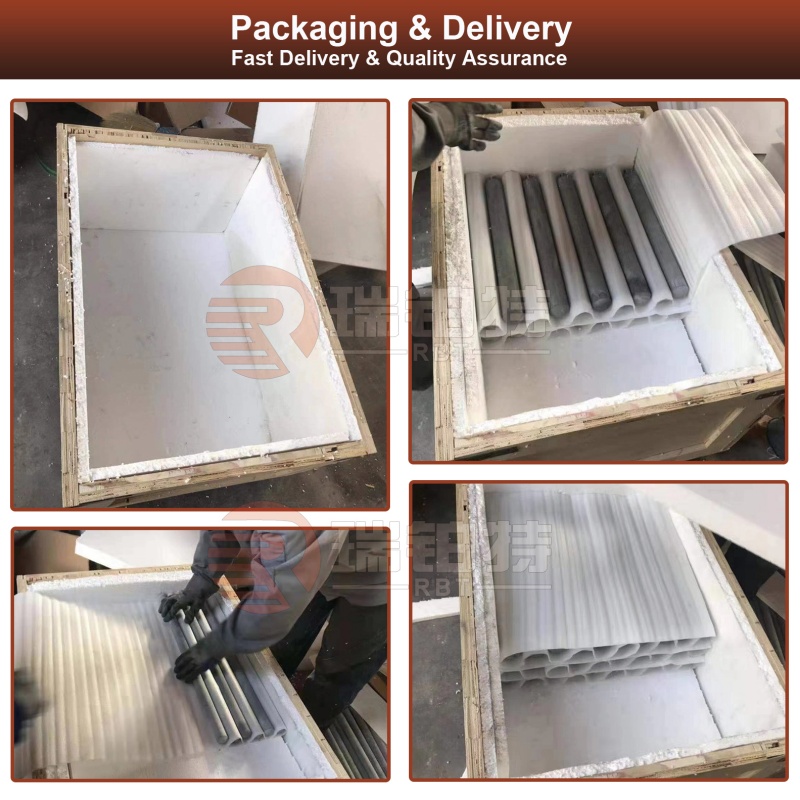

Kwinkqubo nganye yemveliso, i-RBT inenkqubo epheleleyo ye-QC yokwakheka kweekhemikhali kunye neempawu zomzimba. Kwaye siza kuvavanya iimpahla, kwaye isiqinisekiso somgangatho siya kuthunyelwa kunye neempahla. Ukuba uneemfuno ezizodwa, siza kuzama konke okusemandleni ethu ukuzilungiselela.

Ngokuxhomekeke kubungakanani, ixesha lethu lokuhambisa lahlukile. Kodwa sithembisa ukuthumela ngokukhawuleza kangangoko kunokwenzeka ngomgangatho oqinisekisiweyo.

Kakade ke, sinikezela ngeesampuli zasimahla.

Ewe, ewe, wamkelekile ukutyelela inkampani ye-RBT kunye neemveliso zethu.

Akukho mda, singakunika ingcebiso nesisombululo esifanelekileyo ngokwemeko yakho.

Besisenza izinto ezirhabaxa kangangeminyaka engaphezu kwama-30, sinenkxaso yobugcisa enamandla kunye namava amaninzi, singanceda abathengi ukuba bayile ii-kiln ezahlukeneyo kwaye banikezele ngenkonzo enye.