I-Silicon Carbide Dryer Lgniter

Iindidi zeMveliso

1. Iimveliso ze-silicone ye-reaction sintered carbide(IiMveliso ze-RBSiC)

I-Reaction bonded silicon carbide (RBSiC) yimathiriyeli yobunjineli yobunjineli obuphambili eyenza i-silicon carbide bonding isigaba ngokusabela simahla ikhabhoni ngesilicon elulwelo phantsi kweemeko eziphezulu zobushushu. Amacandelo ayo asisiseko abandakanya i-silicon carbide (SiC) matrix kunye ne-silicon yamahhala (Si). Owokuqala ubonelela ngeempawu ezibalaseleyo zoomatshini, ukumelana nokunxiba kunye nokuzinza kobushushu obuphezulu,

ngelixa le yokugqibela igcwalisa i-pores phakathi kwamasuntswana e-silicon carbide ukunyusa ubuninzi kunye nokunyaniseka kwesakhiwo sezinto eziphathekayo.

(1) Iimpawu:

Uzinzo lobushushu obuphezulu:Elona qondo lobushushu liphezulu lokusebenza 1350℃.

Ukumelana nokunxiba kunye nokumelana nomhlwa:Ifanelekile kwiimeko zokusebenza ezinzima zokushisa okuphezulu, i-asidi, i-alkali kunye nesinyithi esinyibilikisiweyo. ...

Ukuhanjiswa okuphezulu kwe-thermal kunye ne-coefficient yokwandisa i-thermal ephantsi:I-thermal conductivity iphezulu njenge-120-200 W / (m·K), kwaye i-coefficient yokwandisa i-thermal kuphela i-4.5 × 10⁻⁶ K⁻¹, ekhusela ngokufanelekileyo ukuqhekeka kwe-thermal kunye nokukhathala kwe-thermal. ...

I-Anti-oxidation:Umaleko oxineneyo we-silica okhuselayo uveliswa kumphezulu kwiqondo lobushushu eliphezulu ukwandisa ubomi benkonzo.

(2) IiMveliso eziphambili:

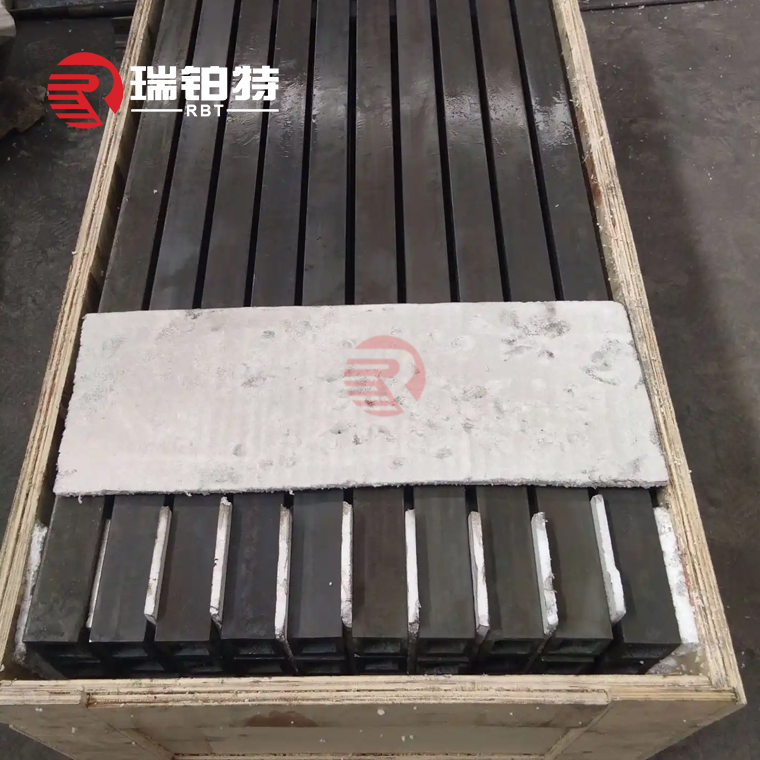

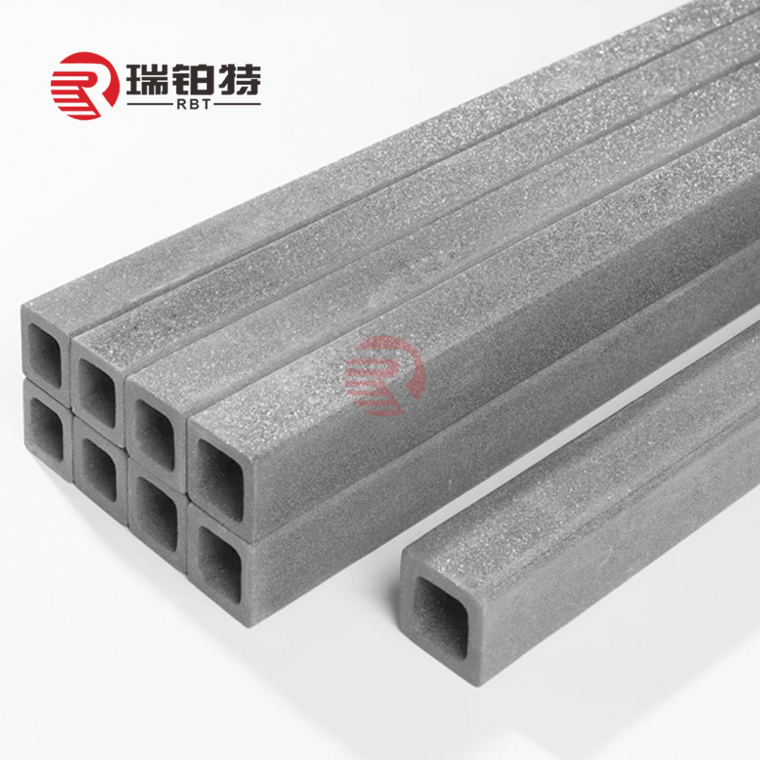

...Umqa we-silicon ye-carbide:isetyenziselwa ukwakhiwa kwesakhiwo esithwala umthwalo weetoni zetonela, ii-shuttle kilns kunye nezinye iikhilni zamashishini, ezinokumelana nobushushu obuphezulu.

...

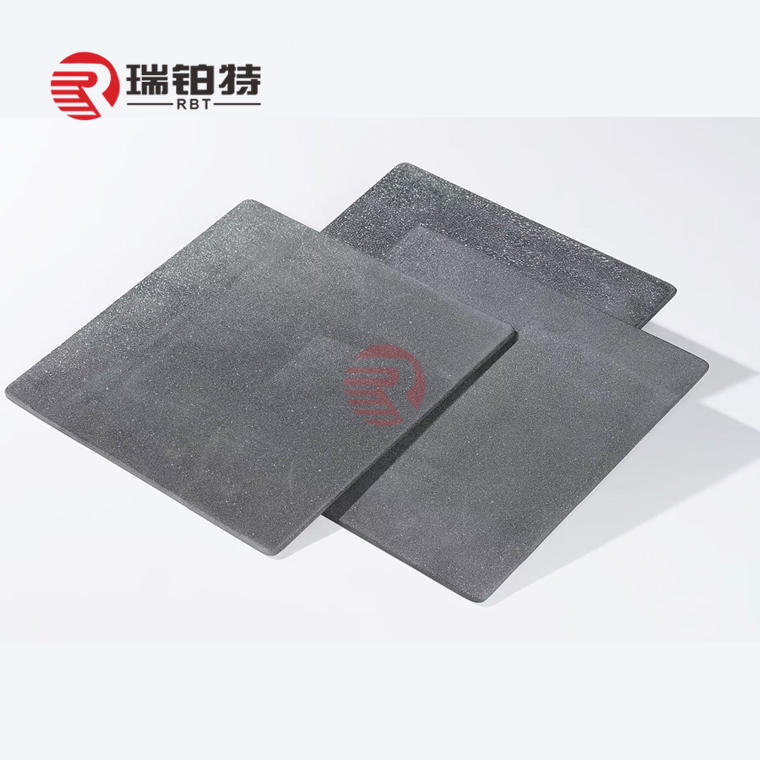

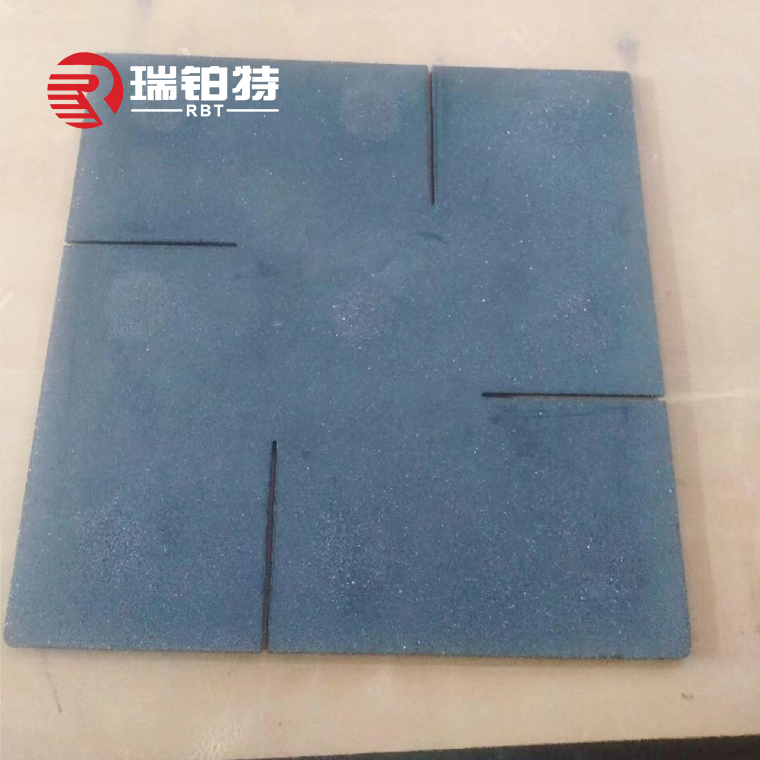

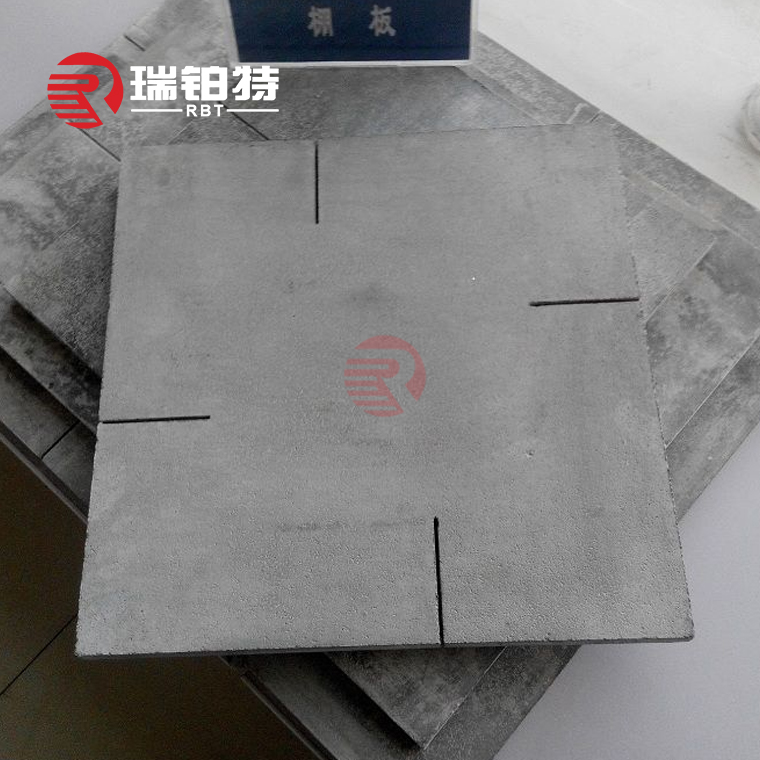

Ipleyiti ye-silicon ye-carbide:esetyenziselwa izinto eziphikisayo kwii-kilns, ezineempawu ze-oxide bonding. ...

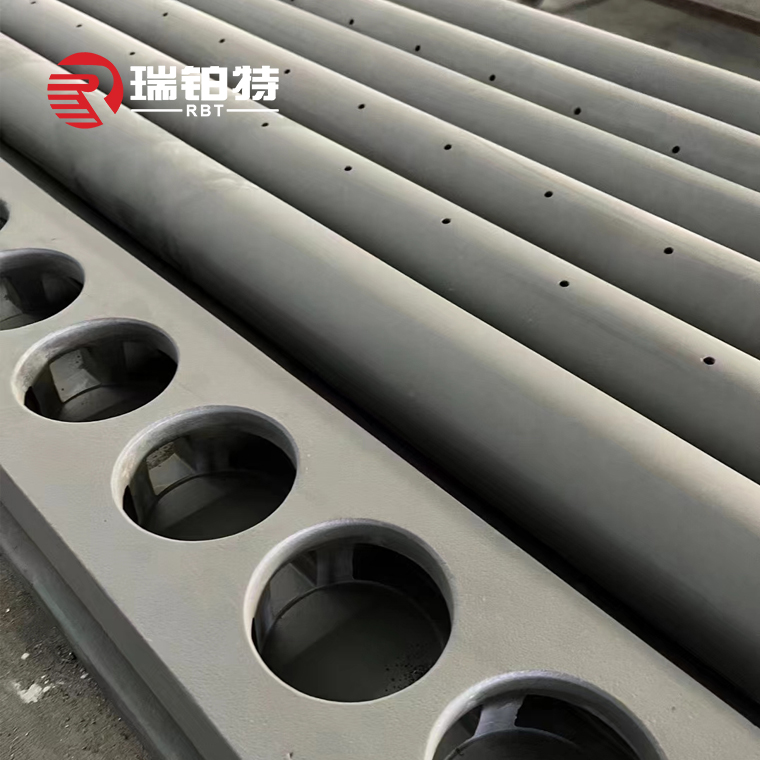

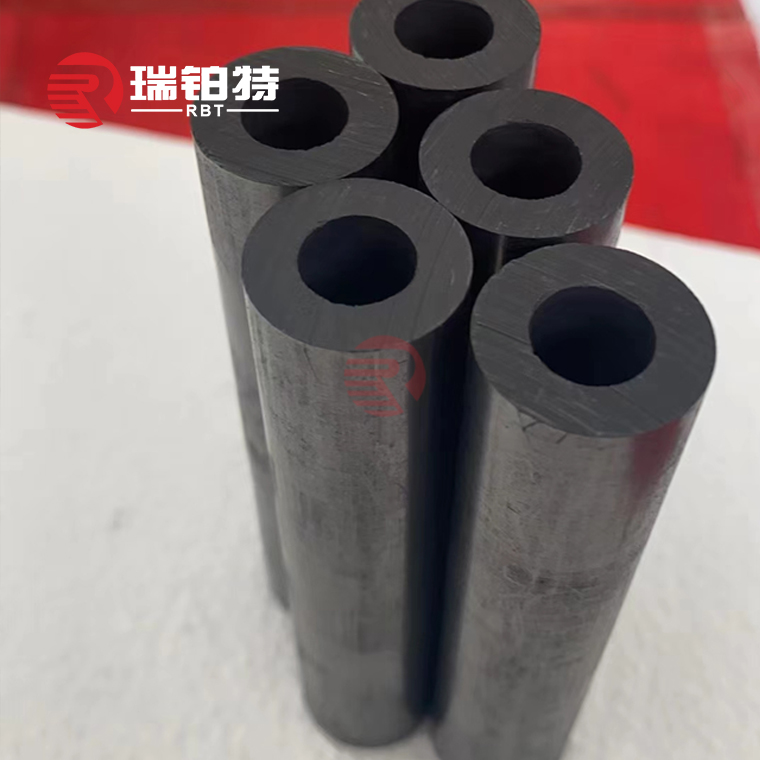

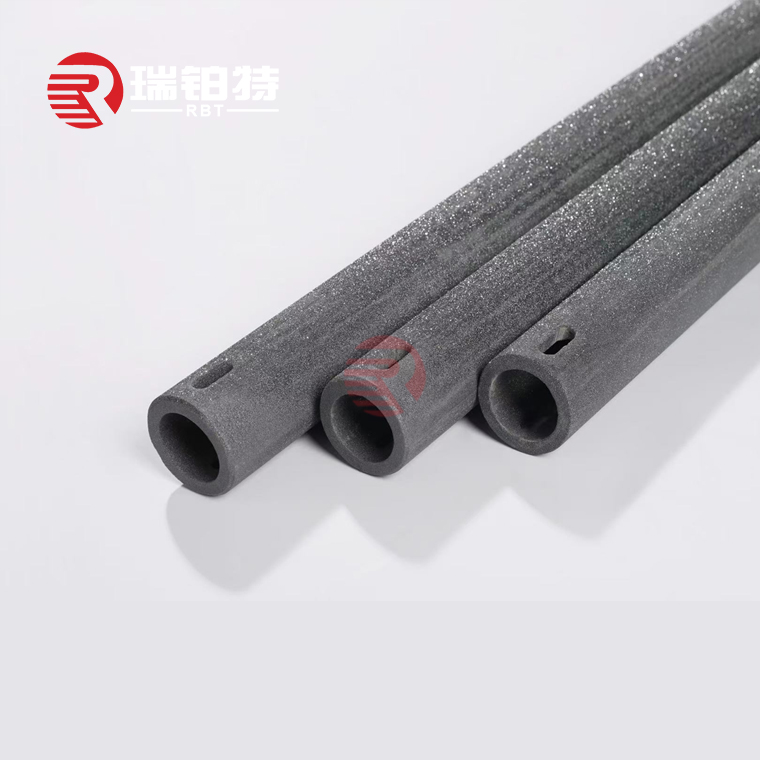

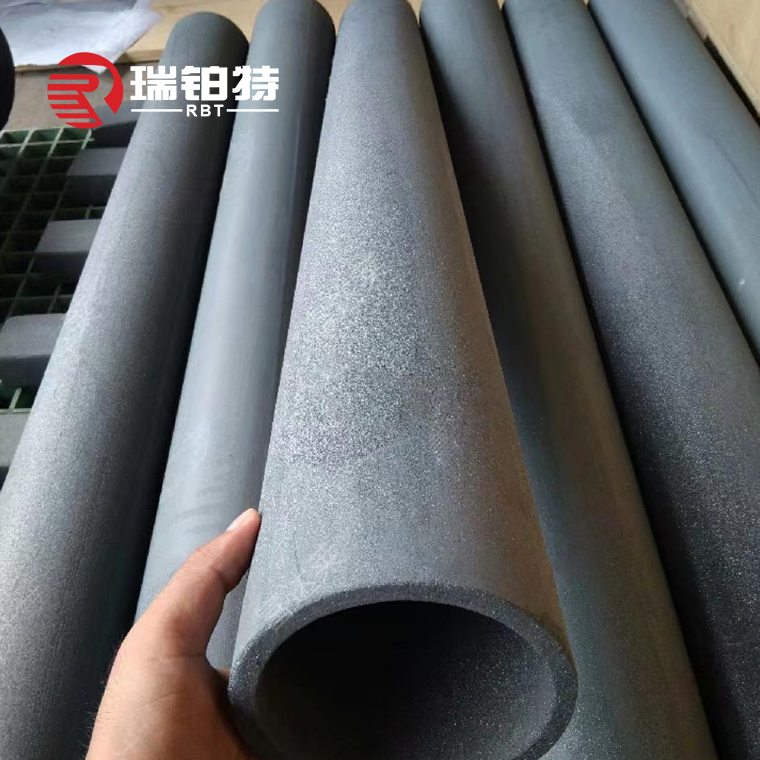

Umbhobho we-silicon ye-carbide:isetyenziselwa imibhobho kunye nezikhongozeli kwiindawo ezahlukeneyo zobushushu obuphezulu. ...

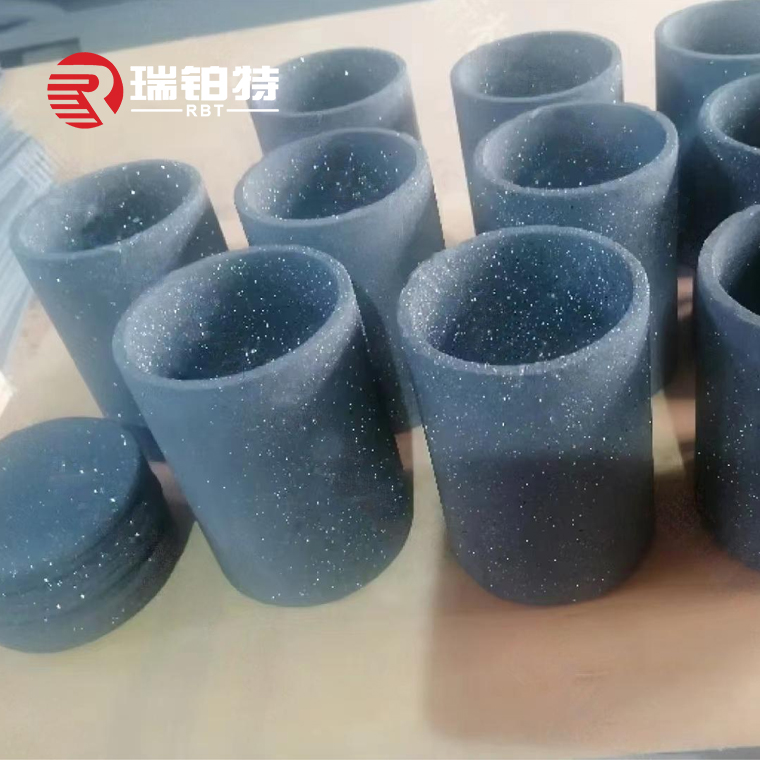

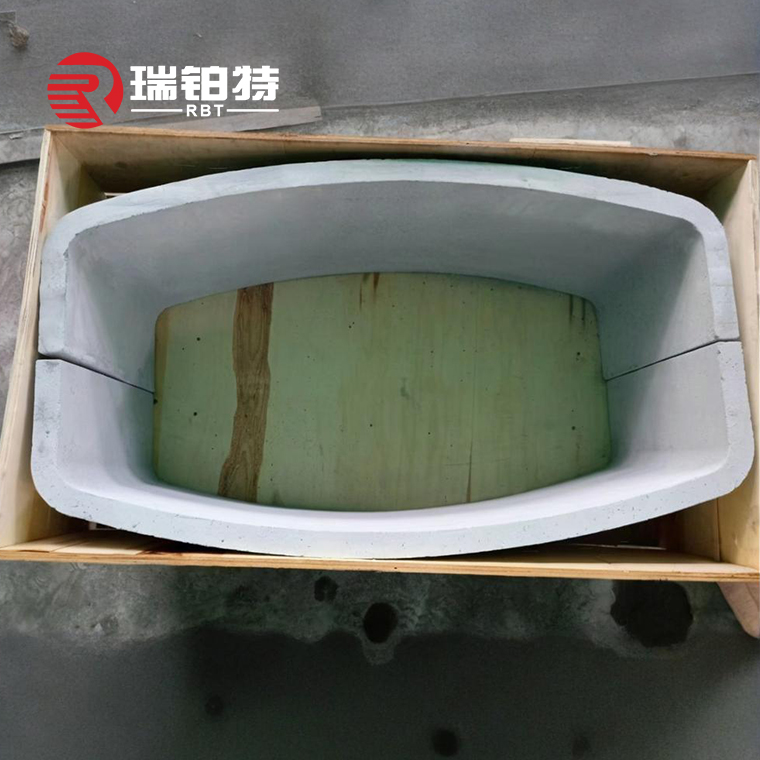

I-silicon ye-carbide crucible kunye ne-sagger:isetyenziselwa ukunyibilikisa ubushushu obuphezulu kunye nokugcinwa kwezinto. ...

Umsesane wokutywina we-silicon carbide:isetyenziswa kakhulu kwimimandla yeemoto, i-aerospace kunye neshishini lemichiza, kwaye inokugcina ukusebenza okuthembekileyo kokutywinwa kubushushu obuphezulu kunye neendawo ezinoxinzelelo oluphezulu. ...

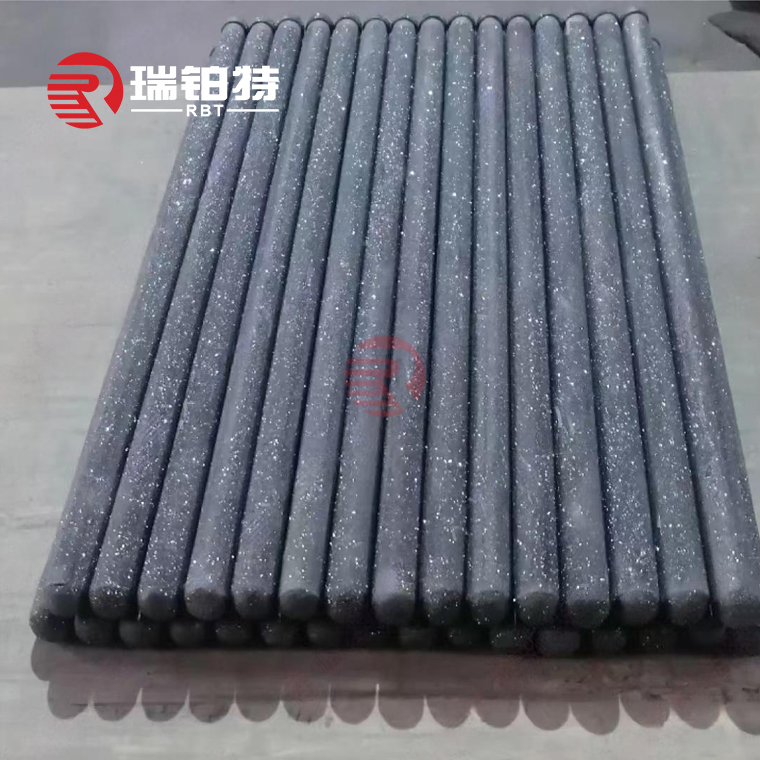

I-silicon carbide roller:esetyenziselwa ii-roller kilns, ezineempawu zokuchasana ne-oxidation, amandla aphezulu obushushu obuguquguqukayo kunye nobomi benkonzo ende. ...

Imibhobho yokupholisa ye-silicon carbide:isetyenziselwa indawo yokupholisa yee-roller kilns, kunye nokuchasana okulungileyo kokugqithisileyo

ingqele kunye nobushushu. ...

Umbhobho weSilicon carbide bunner:esetyenziselwa iintlobo ezahlukeneyo zeoyile, igesi kunye nezinye iikhilni zamashishini, ezineempawu zokubanda kakhulu kunye nokumelana nobushushu, ukumelana nokunxiba, ukumelana nobushushu obuphezulu, njl. ...

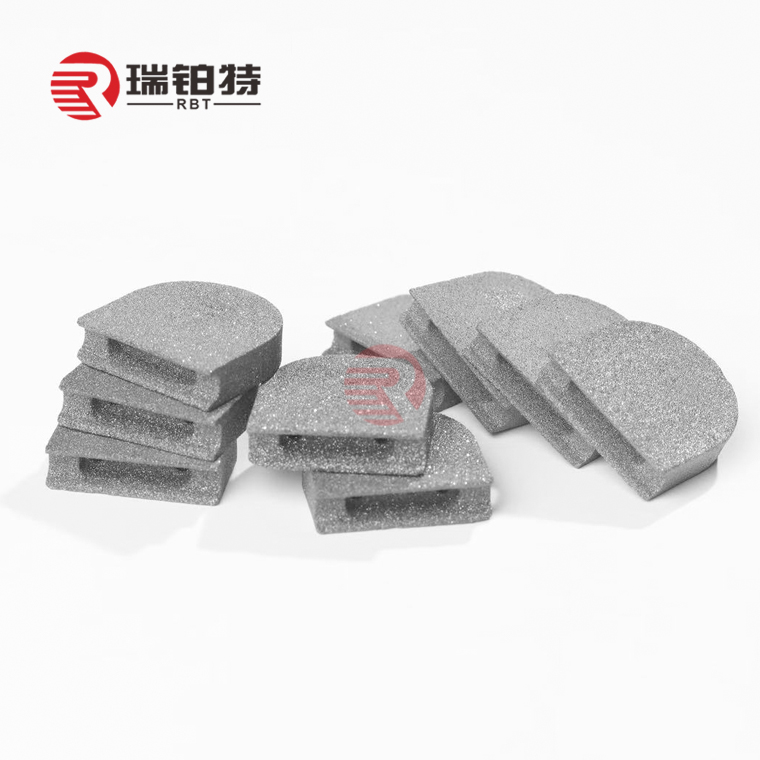

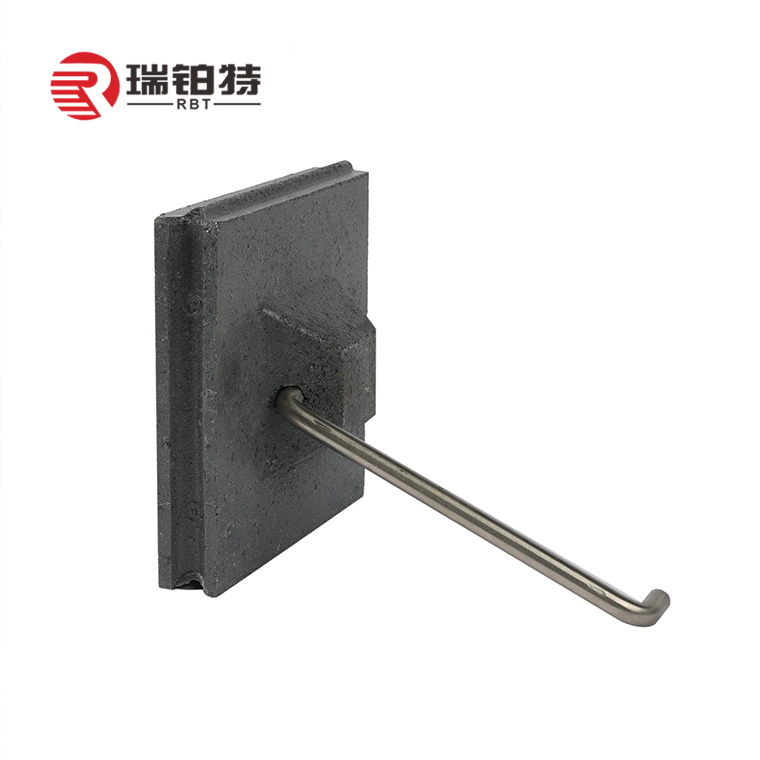

Amalungu alungiselelwe ngokwemilo eyodwa:Imveliso eyenziwe ngokwezifiso yamacandelo ahlukeneyo amile ngokweemfuno zabathengi, ezinje ngeepleyiti ezimile okwentlanzi, iintonga zokuxhoma, iinxalenye zenkxaso, njl.

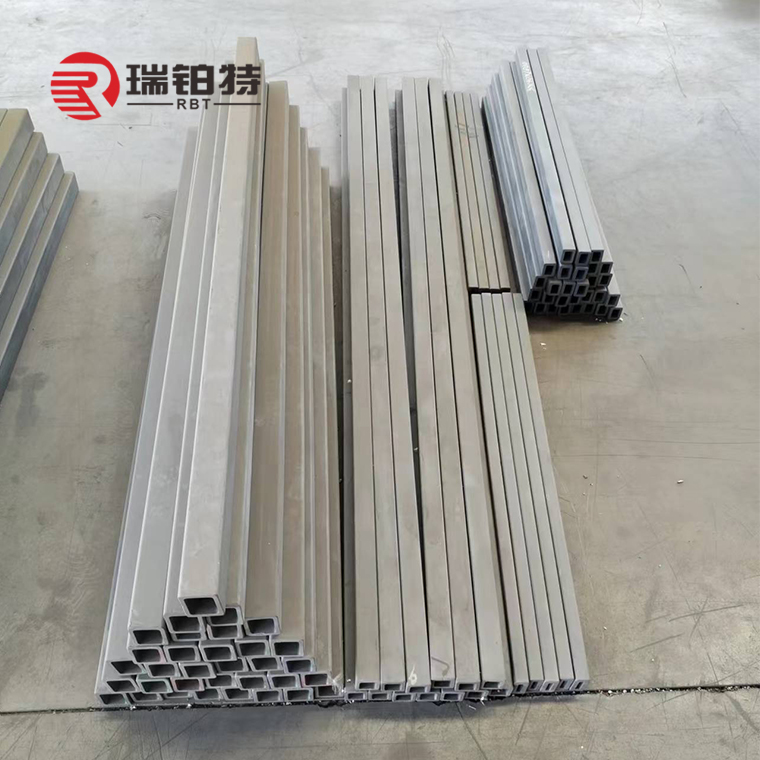

Iinkcukacha Imifanekiso

ISilicon Carbide Beam

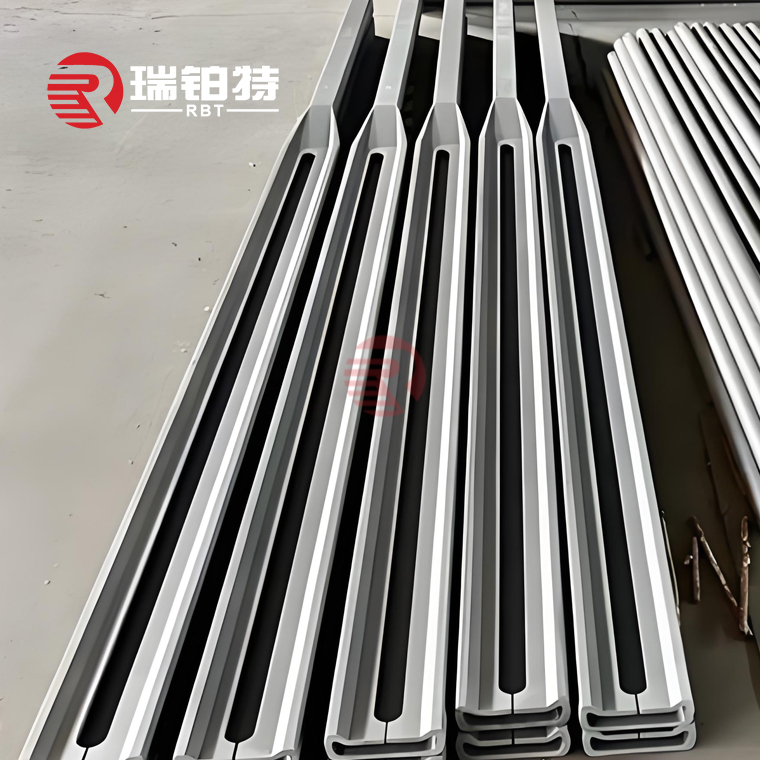

ISilicon Carbide Cantilever Paddle

ISilicon Carbide Nozzle

I-Silicon Carbide Burner Tube

Imibhobho yokupholisa ye-Silicon Carbide

ISilicon Carbide Nozzle

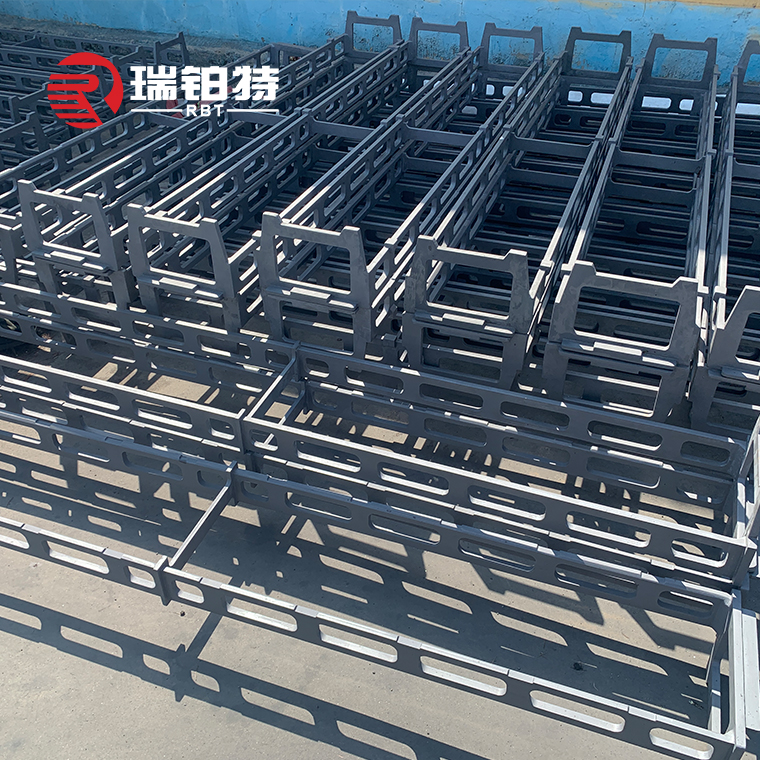

I-Silicon Carbide Boat Bracket

ILining ekwaziyo ukunxiba

Isikhephe seSilicon Carbide Wafer

Isalathiso seMveliso

| Iimveliso ze-RBSiC (SiSiC). | ||

| Into | Iyunithi | Idatha |

| Ubushushu obuphezulu beSicelo | ℃ | ≤1350 |

| Ukuxinana | g/cm3 | ≥3.02 |

| Vula i-Porosity | % | ≤0.1 |

| Ukugoba Amandla | Mpa | 250(20℃); 280(1200℃) |

| Imodyuli ye-Elastictiy | I-Gpa | 330(20℃); 300(1200℃) |

| I-Thermal Conductivity | W/mk | 45(1200℃) |

| I-Coefficient yoKwandiswa kweThermal | K-1*10-6 | 4.5 |

| Ukuqina kukaMoh | | 9.15 |

| I-Acid Alkaline-Ubungqina | | Egqwesileyo |

2. Iimveliso ze-silicon ze-carbide ezingenaxinzelelo (iiMveliso ze-SSiC)

Iimveliso ze-silicon carbide ezingenaxinzelelo ze-sintered luhlobo lwemathiriyeli ye-ceramic yobuchwepheshe obuphezulu elungiswe yinkqubo yokucoca engenaluxinzelelo. Icandelo layo eliphambili yi-silicon carbide (SiC), kwaye inxalenye ethile yezongezo zongezwa. Ngetekhnoloji ye-ceramic ephucukileyo, iyenziwa ukuba ibe yi-non-porous, i-seamless, kunye noxinzelelo olungenaxinzelelo oluphezulu lwe-ceramics.

(1) Iimpawu:

Ukumelana nobushushu obuphezulu:ukusetyenziswa okuqhelekileyo kwi-1800 ℃;

Ukuhanjiswa kwe-thermal ephezulu:ilingana ne-thermal conductivity yegraphiteizixhobo;

Ukuqina okuphezulu:ukuqina okwesibini kuphela kwidayimane kunye ne-cubic boron nitride;

Ukuchasa umhlwa:i-asidi eyomeleleyo kunye ne-alkali eyomeleleyo ayinayo i-corrosion kuyo, kwaye ukumelana kwayo ne-corrosion kungcono kune-tungsten carbide kunye ne-aluminium oxide;

Ubunzima obulula:Ubuninzi be-3.10g / cm3, kufuphi ne-aluminium;

Akukho deformation:i-coefficient yokwandiswa kwe-thermal encinci kakhulu,

Ukumelana nomothuko wobushushu:izinto eziphathekayo ziyakwazi ukumelana nokutshintsha kobushushu obukhawulezayo, ukutshitshiswa kwe-thermal, ukupholisa ngokukhawuleza kunye nokufudumeza, kunye nokusebenza okuzinzile.

(2) IiMveliso eziphambili:

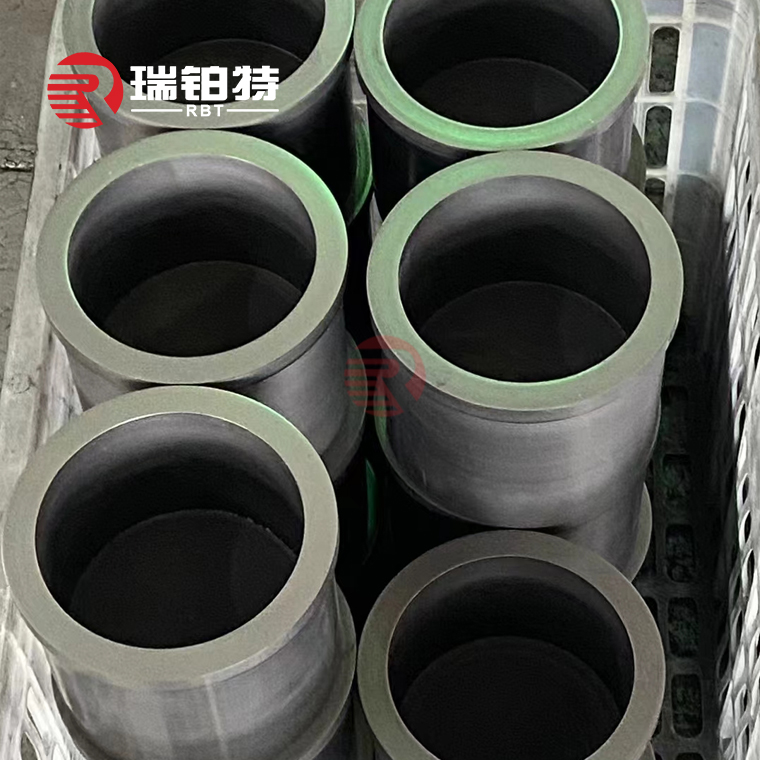

Izangqa zokutywina:Iimveliso ze-silicon ze-carbide ezingenaxinzelelo ze-sintered zihlala zisetyenziselwa ukwenza imisesane yokutywina engagugiyo kunye ne-corrosion-resistant kunye neebheringi ezityibilikayo. ...

Amalungu oomatshini:Kubandakanya iibheringi zobushushu obuphezulu, izitywini zoomatshini, imilomo, iivalvu zepneumatic, imizimba yempompo, izixhobo, njl.

Izixhobo zekhemikhali:Isetyenziselwa ukwenza imibhobho ekwaziyo ukumelana nomhlwa, iitanki zokugcina, izixhobo ezisebenza ngamandla kunye nezitywini. ...

Izixhobo zombane:Kwishishini lamandla, i-silicon carbide engenaxinzelelo isetyenziselwa ukwenza izichasi zobushushu obuphezulu, izinto zokufudumeza zombane kunye nokutshintsha kombane ophezulu. ...

Ifenitshala yeKiln:Okufana nezakhelo zesakhiwo esithwala imithwalo, iirola, imilomo yamadangatye, imibhobho yokupholisa, njl. ...

Iinkcukacha Imifanekiso

ISilicon Carbide Seal Ring

Umbhobho weSilicon Carbide

I-Silicon Carbide Liners

ISilicon Carbide Beam

Icwecwe leSilicon Carbide

ISilicon Carbide yokuSila umphanda

Isalathiso seMveliso

| Iimveliso zeSSiC | ||

| Into | Iyunithi | Isiphumo |

| Ukuqina | HS | ≥115 |

| Inqanaba le-Porosity | % | <0.2 |

| Ukuxinana | g/cm3 | ≥3.10 |

| Amandla acinezelayo | Mpa | ≥2500 |

| Ukugoba Amandla | Mpa | ≥380 |

| I-Coefficient yoKwandiswa | 10-6/℃ | 4.2 |

| Umxholo weSiC | % | ≥98 |

| Mahala Si | % | <1 |

| Imodyuli ye-elastic | I-Gpa | ≥410 |

| Ubushushu obuphezulu beSicelo | ℃ | 1400 |

3. Imveliso ye-silicon ehlaziyiweyo ye-carbide (iiMveliso ze-RSiC)

IRecrystallized Silicon Carbide Products yimveliso ephikisayo eyenziwe nge-silicon carbide ephezulu ecocekileyo njengemathiriyeli ekrwada. Isici sayo esiphambili kukuba akukho sigaba sesibini kwaye siqulunqwe yi-100% α-SiC.

(1) Iimpawu:

Ukuqina okuphezulu:Ukuqina kwayo kukwesibini kuphela kwidayimane, kwaye inamandla omatshini aphezulu kakhulu kunye nokuqina. ...

Ukumelana nobushushu obuphezulu:Inokugcina ukusebenza okuzinzileyo kwindawo yobushushu obuphezulu kwaye ifanelekile kuluhlu lobushushu be-1350 ~ 1600 ℃. ...

Ukuchasa umhlwa okuqinileyo:Inokumelana ne-corrosion ephezulu kwiindidi ezahlukeneyo zeendaba kwaye inokugcinaiipropathi zoomatshini ixesha elide kwiindawo ezonakalisayo ezahlukeneyo. ...

Ukumelana kakuhle ne-oxidation:Inokumelana kakuhle ne-oxidation kwaye inokusebenza ngokuzinzileyo kumaqondo obushushu aphezulu. ...

Ukumelana kakuhle nokothuka kwe-thermal:Isebenza kakuhle kwindawo enotshintsho olukhawulezayo lobushushu kwaye ifanelekile kwindawo ezothusayo zobushushu. ...

Akukho kuncipha ngexesha lokucoca:Ayinciphisi ngexesha lenkqubo ye-sintering, kwaye akukho xinzelelo olushiyekileyo luya kuveliswa ukuze kubangele ukuguqulwa okanye ukuqhekeka kwemveliso. Ilungele ukulungiswa kwamalungu anemilo enzima kunye nokuchaneka okuphezulu.

(2) IiMveliso eziphambili:

Imathiriyeli yefenitshala yeKiln:Isetyenziswa kakhulu kwifenitshala ye-kiln, ineenzuzo zokonga amandla, ukwandisa umthamo osebenzayo we-oven, ukunciphisa umjikelo wokudubula, ukuphucula ukusebenza kakuhle kwemveliso kunye neenzuzo eziphezulu zoqoqosho. ...

Imilomo yeBunner:Ingasetyenziswa njengeentloko zombhobho wokutsha kwaye ifanelekile kwimo engqongileyo yobushushu obuphezulu. ...

Iityhubhu zokufudumeza ngemitha yeCeramic:Ezi ityhubhu zokufudumeza zithatha ithuba lokuzinza kobushushu obuphezulu kunye nokumelana nokugqwala kwe-silicon carbide ehlaziyiweyo kwaye ifanelekile kwizicelo ezahlukeneyo zobushushu obuphezulu. ...

Iityhubhu zokukhusela amalungu:Ngokukodwa kwiziko le-atmosphere, iimveliso ze-silicon carbide ezihlaziyiweyo zisetyenziswa njengeetyhubhu zokukhusela ezinobushushu obuphezulu kunye nokumelana nokubola. ...

Imizimba yempompo yobushushu obuphezulu, ii-impellers, iibheringi, izindlu ze-injini:Kwimimandla yeemoto, i-aerospace kunye nemizi-mveliso yezomkhosi, izixhobo ze-silicon carbide ezihlaziyiweyo zenziwa zibe yimizimba yempompo yobushushu obuphezulu, i-impellers, ii-bearings kunye nezindlu ze-injini, njl. ...

Iinkcukacha Imifanekiso

Izahlulo ezibunjwe ngeSilicon Carbide

Icwecwe leSilicon Carbide

I-Silicon Carbide Roller

ISilicon Carbide Beam

Iityhubhu zoKhuseleko lweSilicon Carbide

Ifanitshala yeKiln

I-Silicon Carbide Sagger

I-Silicon Carbide Crucible

Icwecwe leSilicon Carbide

I-Silicon Carbide Lgniter

Umbhobho weSilicon Carbide

Isitshisi seSilicon Carbide

4. Iimveliso ze-silicon nitride ezibotshelelweyo ze-silicon (iiMveliso ze-NSiC)

Iimveliso ze-silicon nitride ezibotshelelwe kwi-silicon carbide zizinto ezenziwe ngokongeza i-SiC aggregate kwi-industrial silicon powder, esabela nge-nitrogen kubushushu obuphezulu ukuvelisa i-Si3N4 kunye nokudibanisa ngokuqinileyo kunye namasuntswana e-SiC.

(1) Iimpawu:

Ukuqina okuphezulu:Ukuqina kwe-Mohs ye-silicon nitride edityanisiweyo yeemveliso ze-silicon carbide imalunga ne-9, okwesibini kuphela kwidayimane, kwaye yimathiriyeli enobulukhuni obuphezulu phakathi kwemathiriyeli engeyiyo eyentsimbi. ...

Amandla obushushu obuphezulu:Kubushushu obuphezulu be-1200-1400 ℃, amandla kunye nobunzima bezinto zihlala zingatshintshi, kwaye ubushushu bokusebenzisa obukhuselekileyo bunokufikelela kwi-1650-1750 ℃.

...

Uzinzo lweThermal:Inomlinganiselo omncinci wokwandisa i-thermal kunye ne-thermal conductivity ephezulu, akukho lula ukuvelisa uxinzelelo lwe-thermal, inozinzo oluhle lokutshatyalaliswa kwe-thermal kunye nokumelana nokunyuka, kwaye ifanele indawo ebanda kakhulu kunye neshushu. ...

Uzinzo kwiChemical:Iyakwazi ukumelana ne-corrosion kunye ne-oxidation, kwaye inokuhlala izinzile kwiindawo ezahlukeneyo zeekhemikhali. ...

Ukumelana nokunxiba:Inokumelana nokunxiba kakuhle kwaye ifanelekile kwizicelo ezahlukeneyo zemizi-mveliso ngokunxitywa okuqatha.

(2) IiMveliso eziphambili:

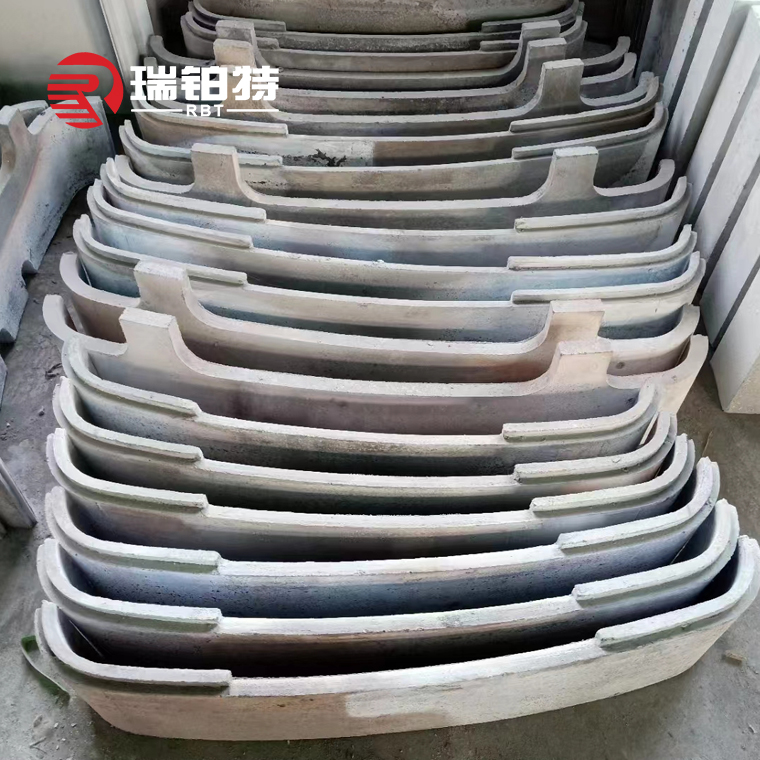

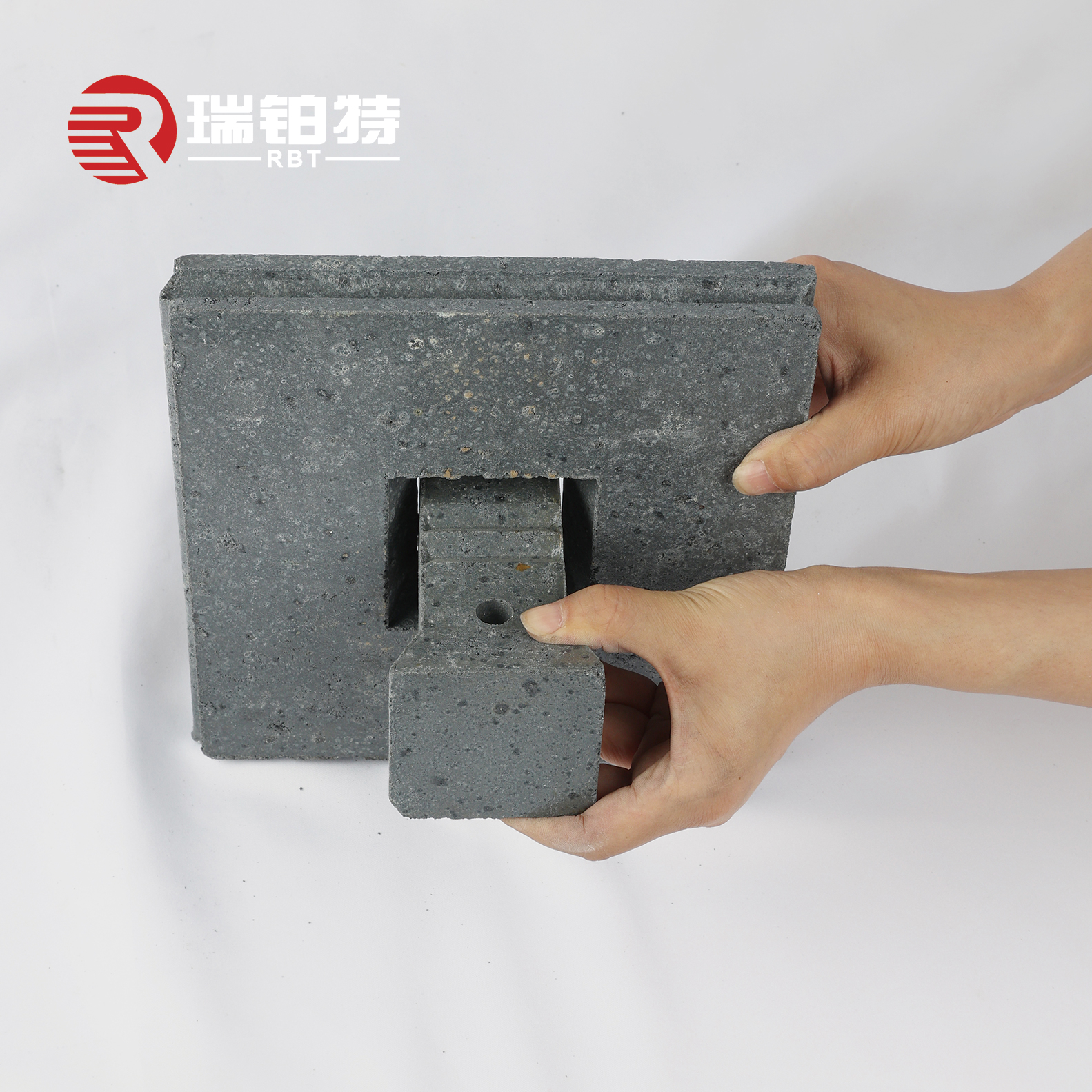

Izitena eziRefractory:isetyenziswa ngokubanzi kwi-aluminiyam ye-electrolytic, i-ironmaking blast furnaces, i-arc furnaces engaphantsi kwamanzi kunye namanye amashishini, aneempawu zokuxhathisa ubushushu obuphezulu, ukuxhathisa ukubola, kunye nokumelana nokukhukuliseka.

Ifenitshala yeKiln:esetyenziselwa i-ceramic grinding wheels, i-porcelain yombane ephezulu yombane, ii-kilns zoshishino, njl.

Iimveliso ezinokwakheka okukhethekileyo:isetyenziswe kwi-non-ferrous metallurgical casting, amandla okushisa, i-arc furnaces engaphantsi kwamanzi kunye namanye amashishini, aneempawu zokumelana nokunxiba kunye nokumelana nokushisa okuphezulu.

Amalungu aphikisayo:kubandakanywa neetyhubhu zokukhusela i-thermocouple, ii-tubes riser, imikhono yokufudumeza, njl., ezisetyenziselwa kwii-kilns eziphezulu zokushisa kunye ne-atmospheres eyahlukeneyo, kunye ne-conductivity ephezulu ye-thermal kunye nokumelana nokugqwala.

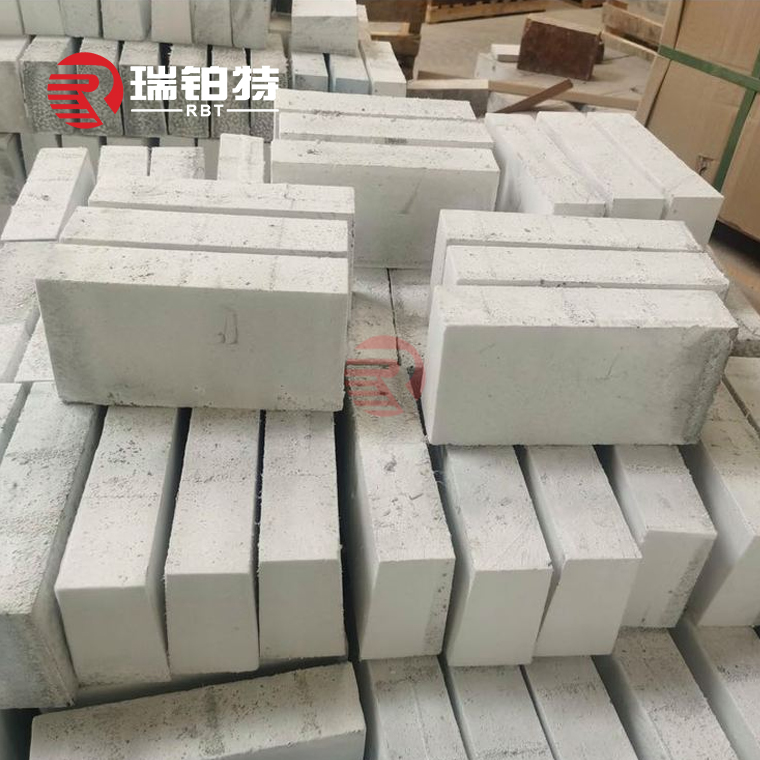

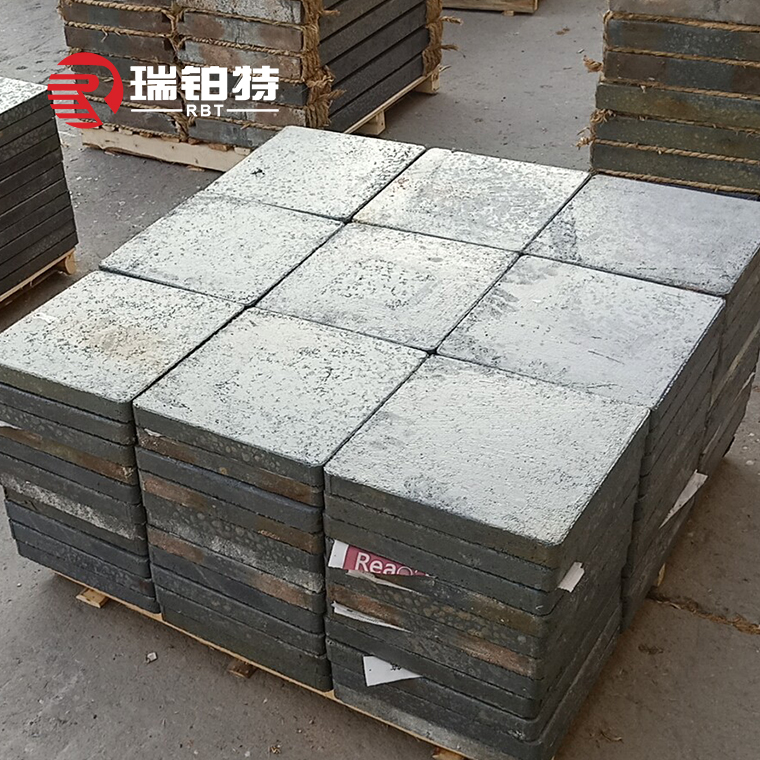

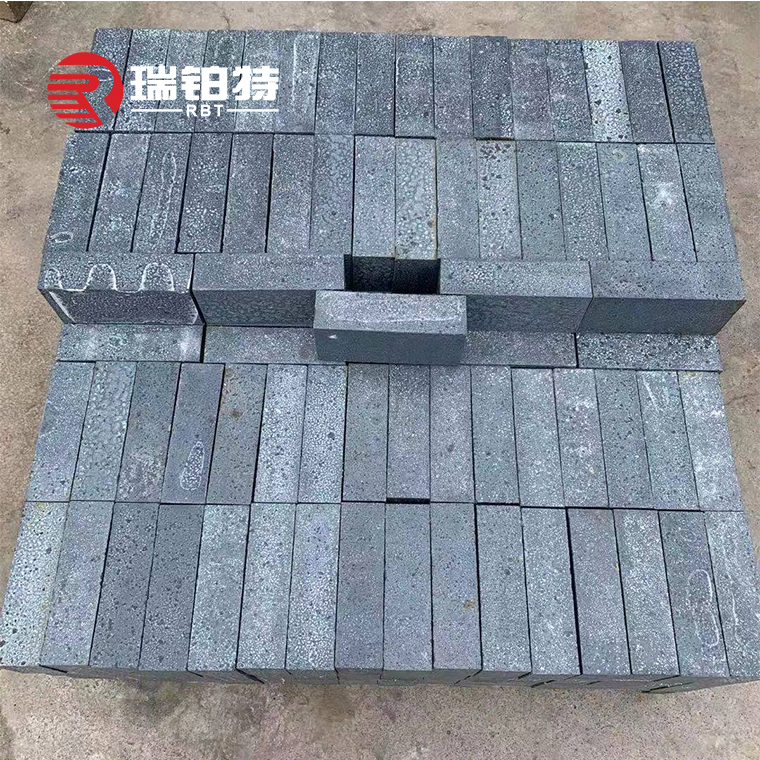

Iinkcukacha Imifanekiso

Icwecwe leSilicon Carbide elimilisekileyo

Icwecwe leSilicon Carbide elimilisekileyo

Icwecwe leSilicon Carbide elimilisekileyo

Icwecwe leSilicon Carbide elimilisekileyo

Icwecwe leSilicon Carbide elimilisekileyo

Iityhubhu zeSilicon Carbide Radiation

Umbhobho weSilicon Carbide

Icwecwe leSilicon Carbide elimilisekileyo

Izahlulo ezibunjwe ngeSilicon Carbide

Iityhubhu zoKhuseleko lweSilicon Carbide

Icwecwe leSilicon Carbide

Izitena zeSilicon Carbide

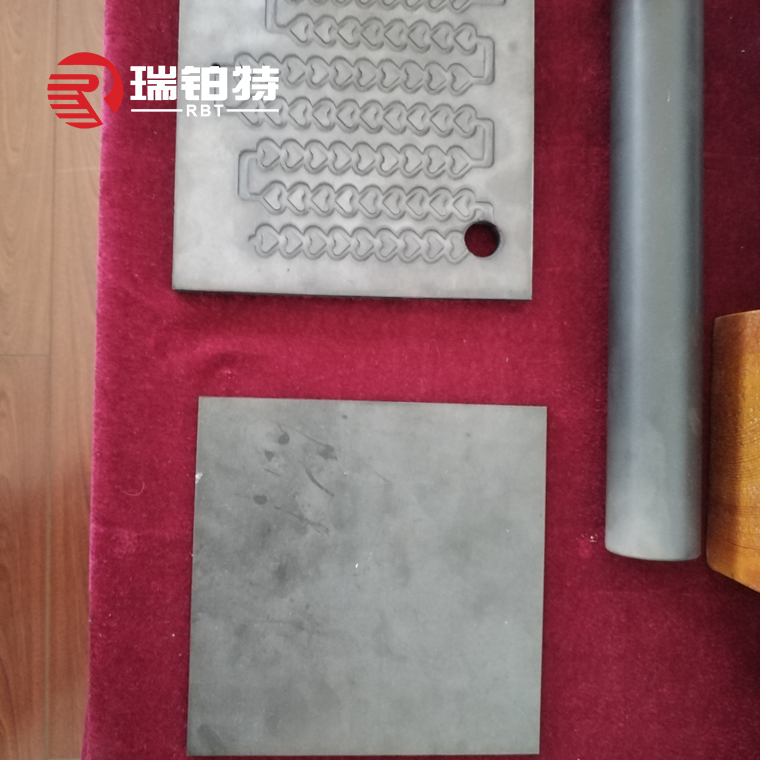

5. Iimveliso ze-silicon carbide eziboshwe nge-oxide

Iimveliso ze-silicon carbide eziboshwe nge-oxide zenziwe ngokuxuba amasuntswana e-silicon carbide kunye ne-oxide powder (efana ne-silicon dioxide okanye i-mullite), ukucinezela kunye ne-sintering kwiqondo lokushisa eliphezulu. Uphawu lwayo kukuba ngexesha le-sintering kunye nokusetyenziswa kwenkqubo, ifilimu ye-oxide ihlanganiswe kwiinqununu ze-silicon carbide, eziphucula kakhulu ukuchasana kwe-oxidation kunye namandla okushisa aphezulu.

Ineempawu zamandla aphezulu obushushu obuguquguqukayo, uzinzo oluhle lokuthotywa kwe-thermal, ukuhanjiswa okuphezulu kwe-thermal, ukuxhathisa ukunxiba kunye nokuchasana okuqinileyo nokhukuliseko oluhlukeneyo lwe-atmosphere, kwaye yinto efanelekileyo yokugcina amandla kwiziko lemizi mveliso.

(2) IiMveliso eziphambili:

Iimveliso zesilicon diokside ezidityanisiweyo ze-silicon carbide:Le mveliso isebenzisa i-silicon dioxide (SiO2) njengesigaba sokubopha. Ngokuqhelekileyo i-5% ~ 10% ye-silicon dioxide powder okanye i-quartz powder ixutywe kunye neengqungquthela ze-silicon carbide (SiC). Ngamanye amaxesha kongezwa i-flux. Emva kokucofa kunye nokwenza, itshiswa kwi-oven jikelele. Uphawu lwayo kukuba ngexesha lokudubula kunye nokusetyenziswa kwenkqubo, ifilimu ye-silicon dioxide ihlanganiswe kwiinqununu ze-silicon carbide, eziphucula kakhulu ukuchasana kwe-oxidation kunye namandla okushisa aphezulu. Le mveliso isetyenziswa kakhulu kwiishelfu ze-kiln yokudubula i-porcelain (> 1300 ℃), kwaye ubomi bayo benkonzo bungaphezulu koku.

iphindwe kabini leyo yeemveliso zesilicon carbide ezibotshelelwe ngodongwe. ...

Iimveliso ze-silicon carbide ezibotshelelwe yiMullite:Le mveliso yongeza i-α-Al2O3 powder kunye ne-silicon dioxide powder kwi-silicon carbide izithako. Emva kokucofa kunye nokwenza, i-Al2O3 kunye ne-SiO2 idityaniswe ukuze yenze i-mullite ngexesha lenkqubo ye-sintering. Ngexesha lokusetyenziswa, i-silicon dioxide eyenziwe yi-oxidation ye-silicon carbide ibumba i-mullite kunye ne-Al2O3. Esi sixhobo sinozinzo oluhle lokutshatyalaliswa kwe-thermal kwaye lusetyenziswa ngokubanzi ekwenzeni i-porcelain saggers kunye neeshelufa.

Iinkcukacha Imifanekiso

Icwecwe leSilicon Carbide

Izitena zeSilicon Carbide

Icwecwe leSilicon Carbide

I-SiC Microcrystalline Pipe

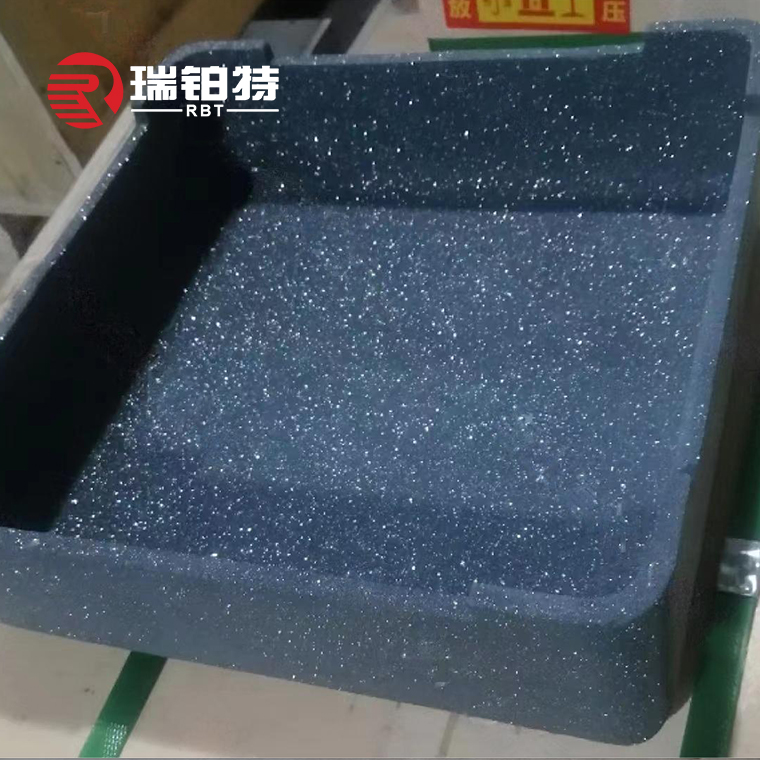

Ibhodi yeSiC Microcrystalline

Ibhodi yeSiC Microcrystalline

Iprofayile yekhampani

Shandong Robert New Material Co., Ltd.ibekwe kwisiXeko saseZibo, kwiPhondo laseShandong, eTshayina, esisiseko sokuvelisa izinto ezichasayo. Siyishishini lanamhlanje elidibanisa uphando kunye nophuhliso, imveliso, intengiso, uyilo lwe-kiln kunye nolwakhiwo, itekhnoloji, kunye nezinto zokuthumela ngaphandle. Sinezixhobo ezipheleleyo, itekhnoloji ephucukileyo, amandla obuchule obuqinileyo, umgangatho wemveliso ogqwesileyo, kunye nodumo oluhle. Umzi-mveliso wethu ugubungela iihektare ezingaphezulu kwama-200 kwaye imveliso yonyaka yezinto ezimilise okwemilo imalunga neetoni ezingama-30000 kunye nemathiriyeli engamiliselwanga yerefractory ziitoni eziyi-12000.

Iimveliso zethu eziphambili zemathiriyeli ye-refractory ziquka:izinto zokunqanda i-alkaline; i-aluminiyam i-silicon refractory izinto; izinto zokuchasa ezingamiliselwanga; izinto zokunqanda ukushisa kwe-thermal; izixhobo ezikhethekileyo zokuchasa; izinto ezisebenzayo zokunqanda iinkqubo zokuphosa eziqhubekayo.

Imibuzo ebuzwa qho

Dinga uncedo? Qiniseka ukuba undwendwela iiforam zethu zenkxaso ukuze ufumane iimpendulo kwimibuzo yakho!

Singumvelisi wokwenyani, umzi-mveliso wethu ukhethekileyo ekuveliseni izinto eziphikisayo iminyaka engaphezu kwama-30. Sithembisa ukubonelela ngexabiso elingcono, elona xabiso lilungileyo lokuthengisa kwangaphambili kunye nenkonzo emva kokuthengisa.

Kwinkqubo nganye yokuvelisa, i-RBT inenkqubo epheleleyo ye-QC yokwakheka kweekhemikhali kunye neempawu ezibonakalayo. Kwaye siya kuvavanya iimpahla, kwaye isatifikethi somgangatho siya kuthunyelwa kunye neempahla. Ukuba uneemfuno ezizodwa, siya kuzama konke okusemandleni ethu ukuze sizilungiselele.

Ngokuxhomekeke kubungakanani, ixesha lethu lokuhambisa lihlukile. Kodwa sithembisa ukuthumela ngokukhawuleza kunye nomgangatho oqinisekisiweyo.

Ngokuqinisekileyo, sinikezela ngeesampuli zamahhala.

Ewe, kunjalo, wamkelekile ukuba undwendwele inkampani ye-RBT kunye neemveliso zethu.

Akukho mda, sinokubonelela ngengcebiso kunye nesisombululo esilungileyo ngokwemeko yakho.

Senze izinto eziphikisayo iminyaka engaphezu kwe-30, sinenkxaso eqinile yobugcisa kunye namava atyebileyo, sinokunceda abathengi bayile ii-kilns ezahlukeneyo kunye nokubonelela ngenkonzo yokumisa enye.