I-Lgniter yeSilicon Carbide Dryer

Iindidi zeMveliso

1. Iimveliso ze-silicon carbide ezisinkiweyo zeReaction (iiMveliso ze-RBSiC)

I-Reaction bonded silicon carbide (RBSiC) sisixhobo sobunjineli esiphucukileyo esivelisa isigaba sokubopha i-silicon carbide ngokuphendula i-free carbon kunye ne-liquid silicon phantsi kweemeko zobushushu obuphezulu. Izinto zayo ezisisiseko ziquka i-silicon carbide matrix (SiC) kunye ne-free silicon (Si). Eyokuqala inika iipropati ezintle zoomatshini, ukumelana nokuguguleka kunye nozinzo lobushushu obuphezulu,

ngelixa le yokugqibela igcwalisa iimbobo eziphakathi kwamasuntswana e-silicon carbide ukuphucula uxinano kunye nokuqina kwesakhiwo sezinto.

(1) Iimpawu:

Uzinzo lobushushu obuphezulu:Ubushushu obuphezulu bokusebenza yi-1350℃.

Ukumelana nokugqwala kunye nokumelana nokugqwala:Ifanelekile kwiimeko ezinzima zokusebenza zobushushu obuphezulu, i-asidi, i-alkali kunye nesinyithi esinyibilikisiweyo.

Ukuqhuba okuphezulu kobushushu kunye ne-coefficient yokwandiswa kobushushu obuphantsi:Ulawulo lobushushu lufikelela kwi-120-200 W/(m·K), kwaye i-thermal expansion coefficient yi-4.5×10⁻⁶ K⁻¹ kuphela, nto leyo ethintela ngempumelelo ukuqhekeka kobushushu kunye nokudinwa kobushushu.

Ukuthintela i-oxidation:Umaleko okhuselekileyo we-silica oxineneyo wenziwa phezu komphezulu kubushushu obuphezulu ukuze kwandiswe ubomi benkonzo.

(2) Iimveliso eziphambili:

Umqadi we-silicon carbide:isetyenziselwa ulwakhiwo lwee-kilns ze-tunnel, ii-kilns ze-shuttle kunye nezinye ii-kilns zoshishino ezithwala umthwalo, ezinokumelana nobushushu obuphezulu kakhulu.

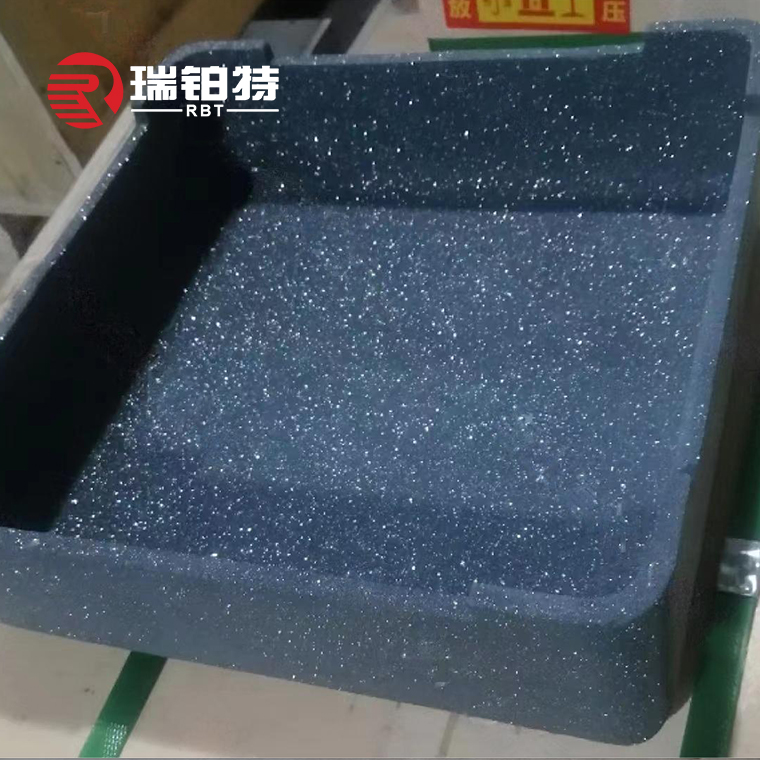

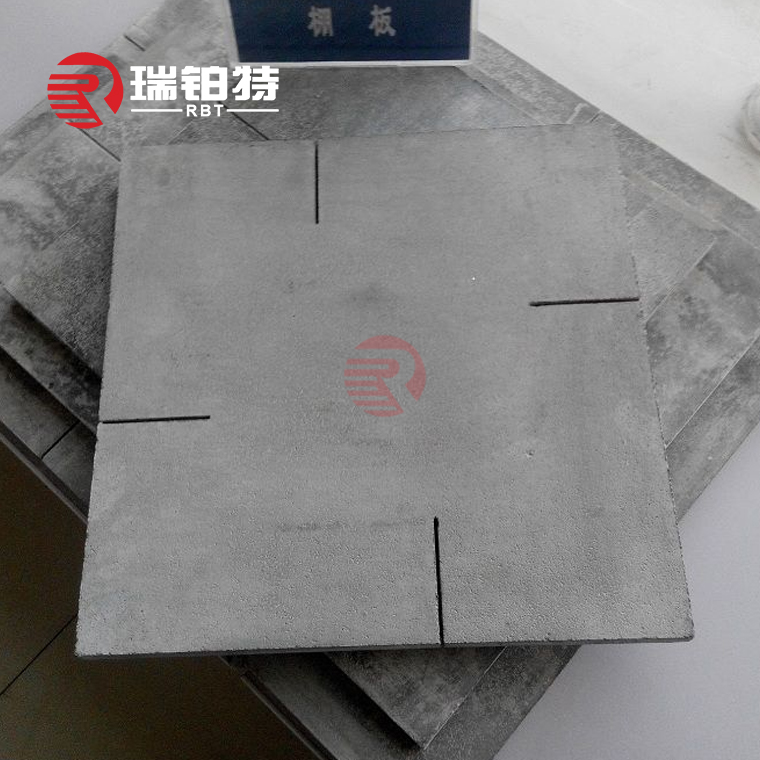

Ipleyiti ye-silicon carbide:isetyenziselwa izinto ezirhabaxa kwii-oven, ezineempawu zokubopha i-oxide.

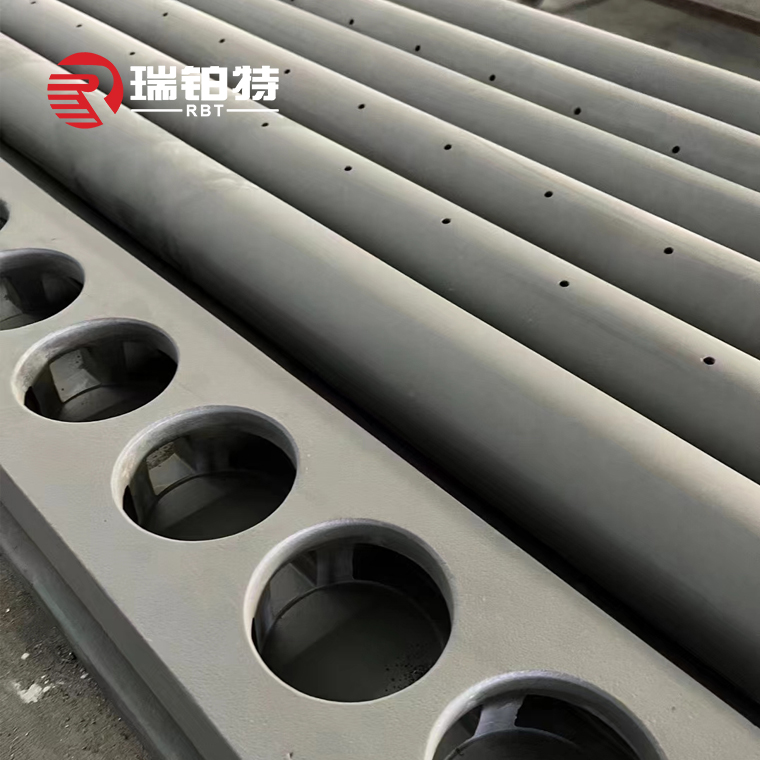

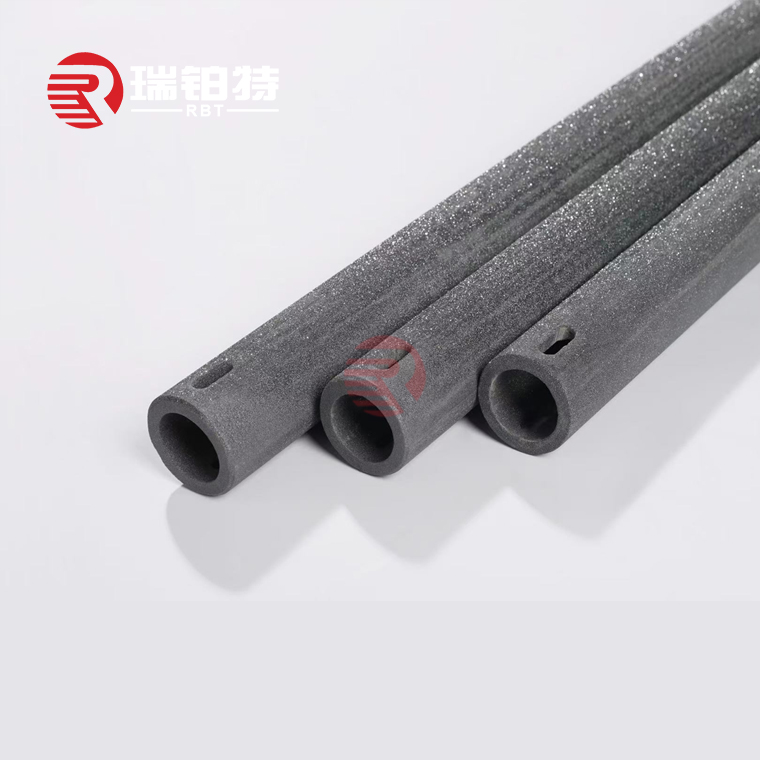

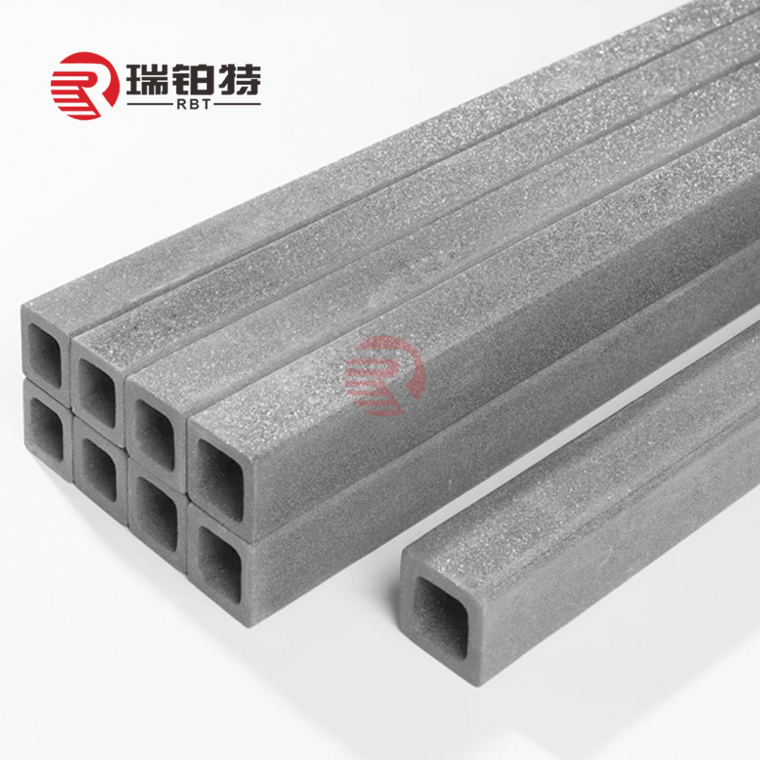

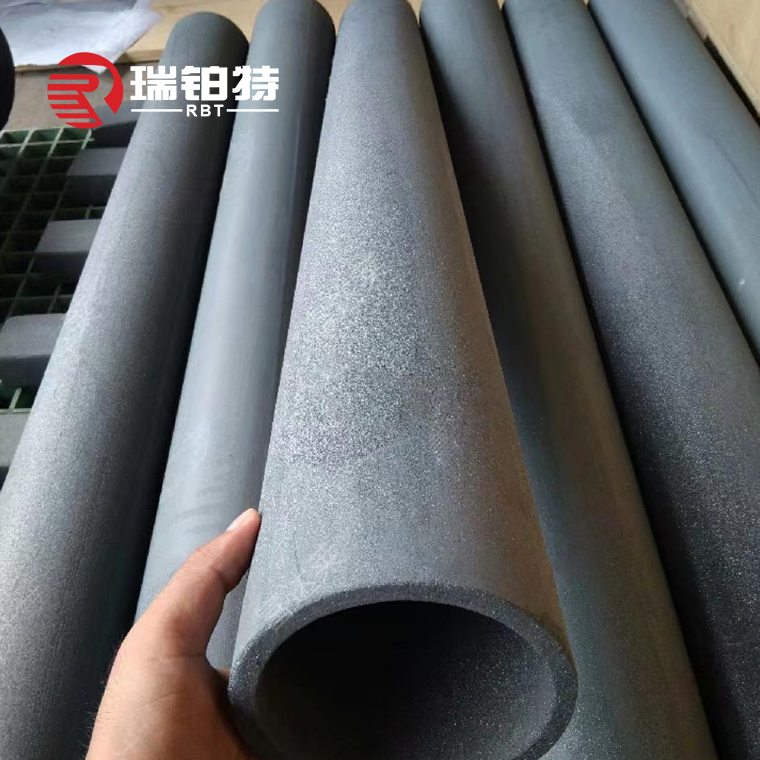

Umbhobho we-silicon carbide:isetyenziselwa imibhobho kunye nezikhongozeli kwiindawo ezahlukeneyo zobushushu obuphezulu.

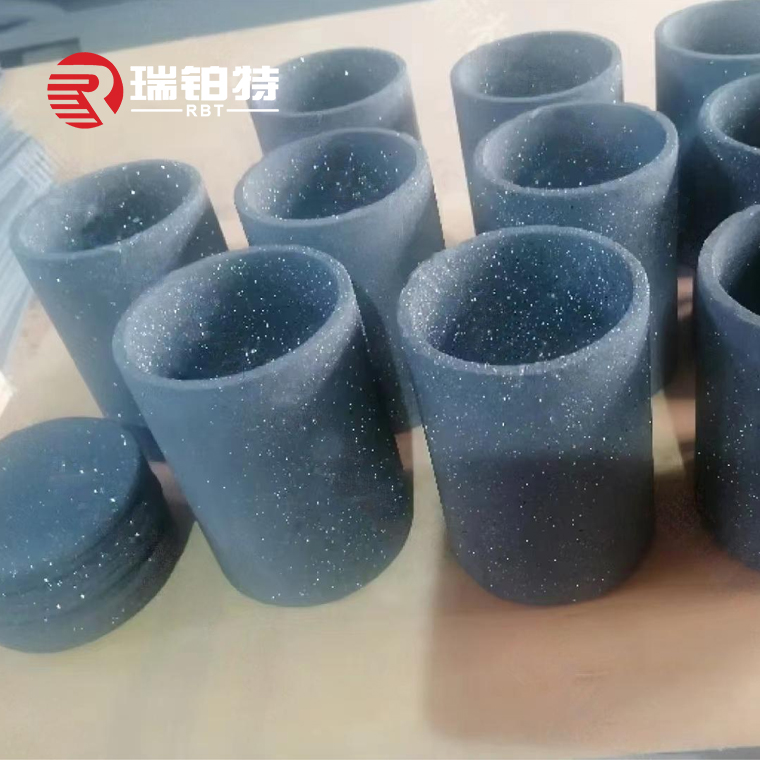

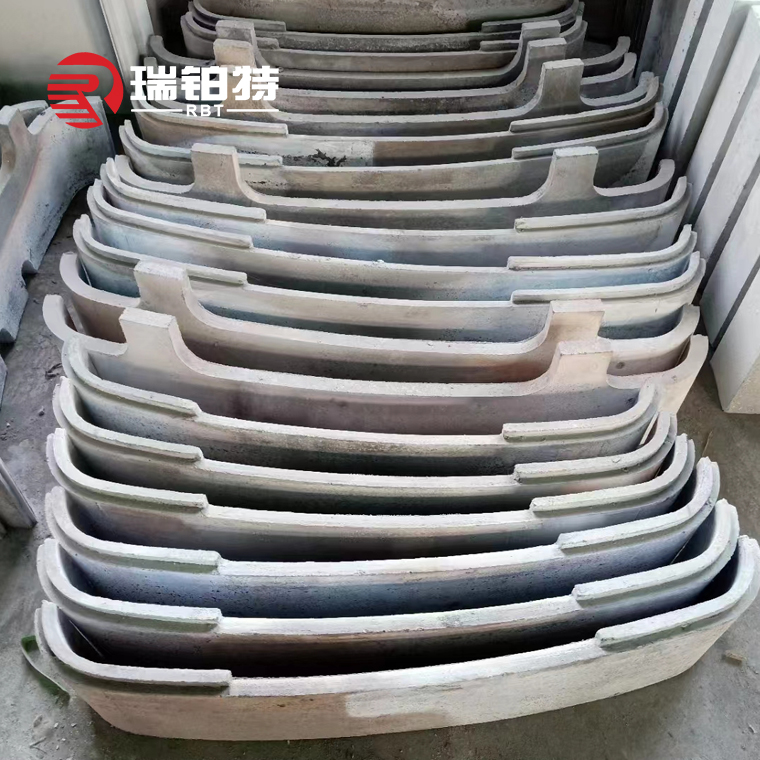

I-silicon carbide crucible kunye ne-sagger:isetyenziselwa ukunyibilikisa nokugcina izinto kubushushu obuphezulu.

Indandatho yetywina ye-silicon carbide:Isetyenziswa kakhulu kwiinkalo zeemoto, i-aerospace kunye neshishini leekhemikhali, kwaye ingagcina ukusebenza okuthembekileyo kokutywina kwiindawo ezinobushushu obuphezulu kunye noxinzelelo oluphezulu.

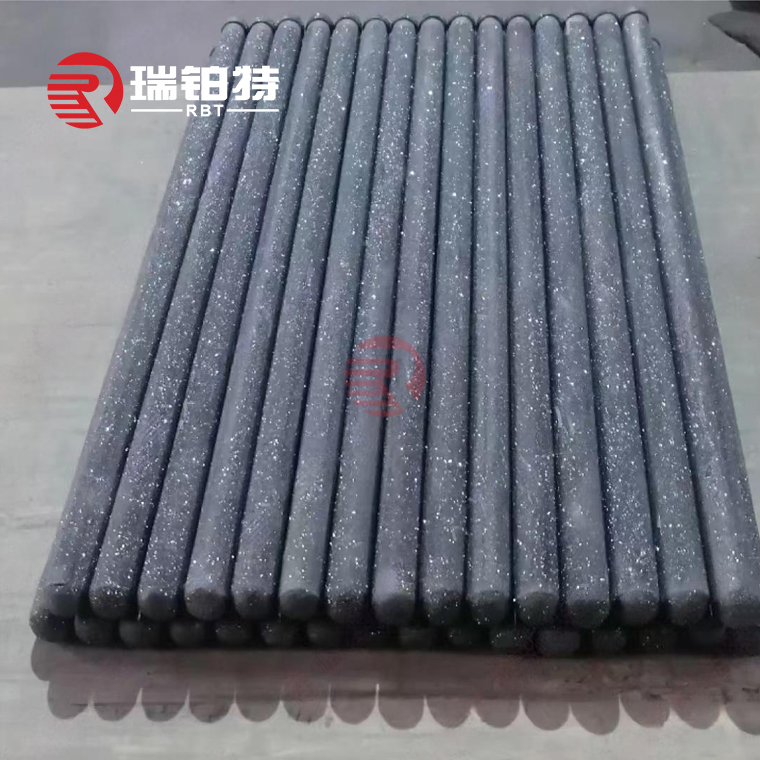

Irola ye-silicon carbide:isetyenziselwa ii-roller oils, eneempawu zokulwa ne-oxidation, amandla aphezulu okuguquguquka kunye nobomi obude benkonzo.

Imibhobho yokupholisa i-silicon carbide:isetyenziselwa indawo yokupholisa yee-roller kilns, enokumelana kakuhle nokugqithisileyo

ukubanda nobushushu.

Umbhobho weSilicon carbide bunner:isetyenziselwa ii-oyile ezahlukeneyo, igesi kunye nezinye ii-oyile zoshishino, ezineempawu zokubanda kakhulu kunye nokumelana nobushushu, ukumelana nokuguguleka, ukumelana nobushushu obuphezulu, njl.njl.

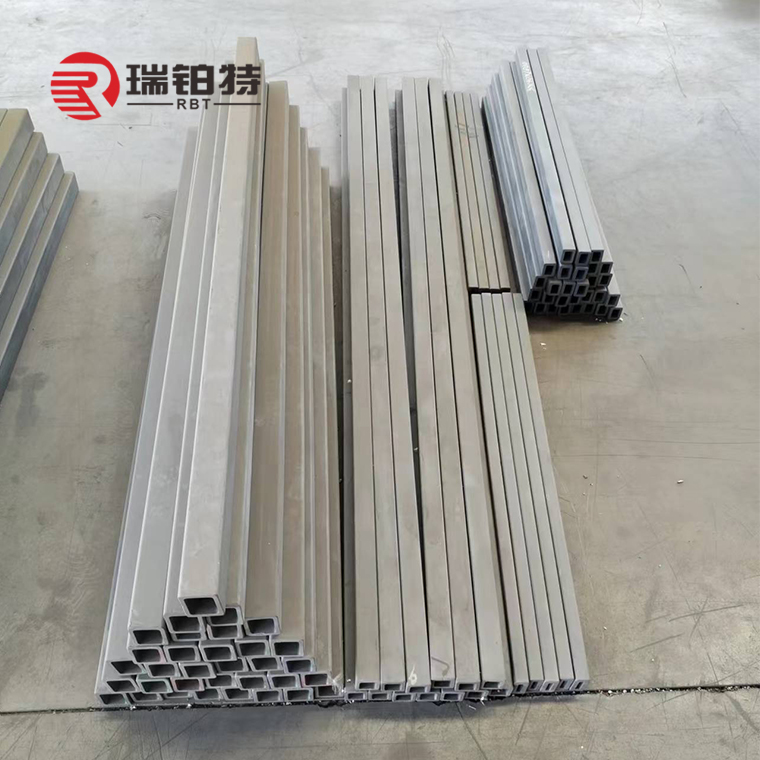

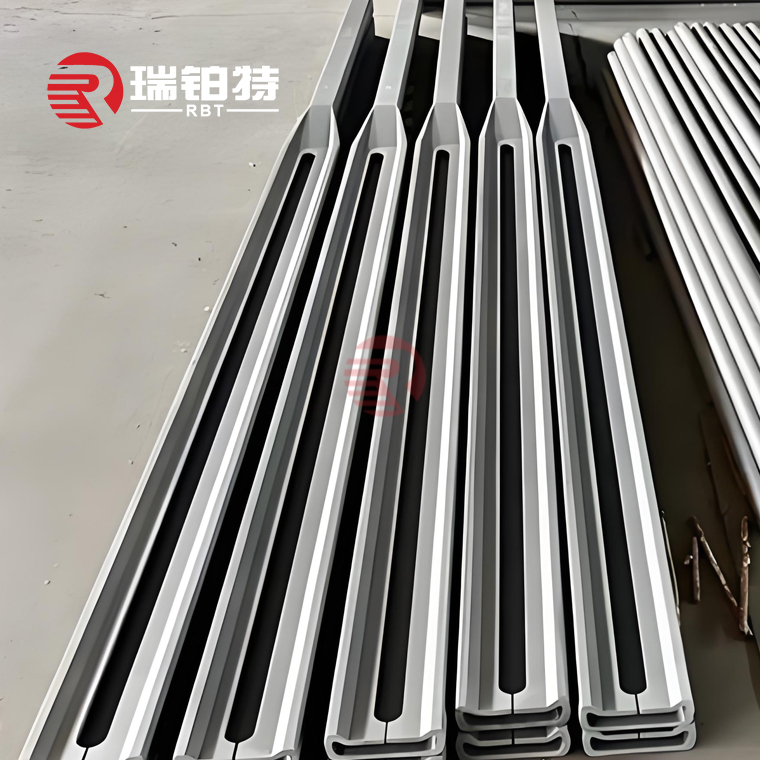

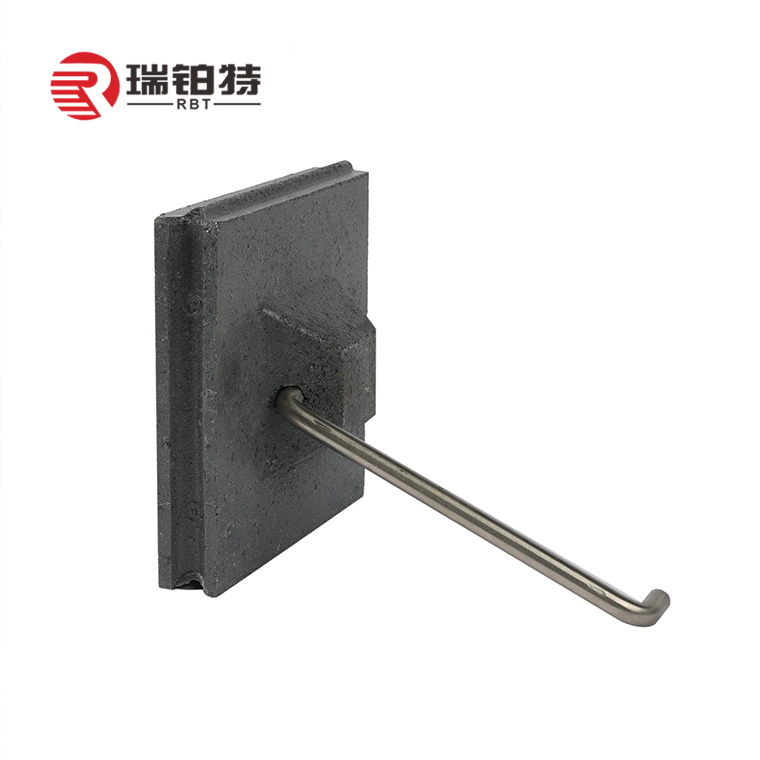

Iindawo ezimile okwenzelwe wena:Imveliso eyenzelwe wena yeendawo ezahlukeneyo ezineemilo ezikhethekileyo ngokweemfuno zabathengi, ezinje ngeepleyiti ezineemilo zentlanzi, iintonga zokuxhoma, iindawo zokuxhasa, njl.njl.

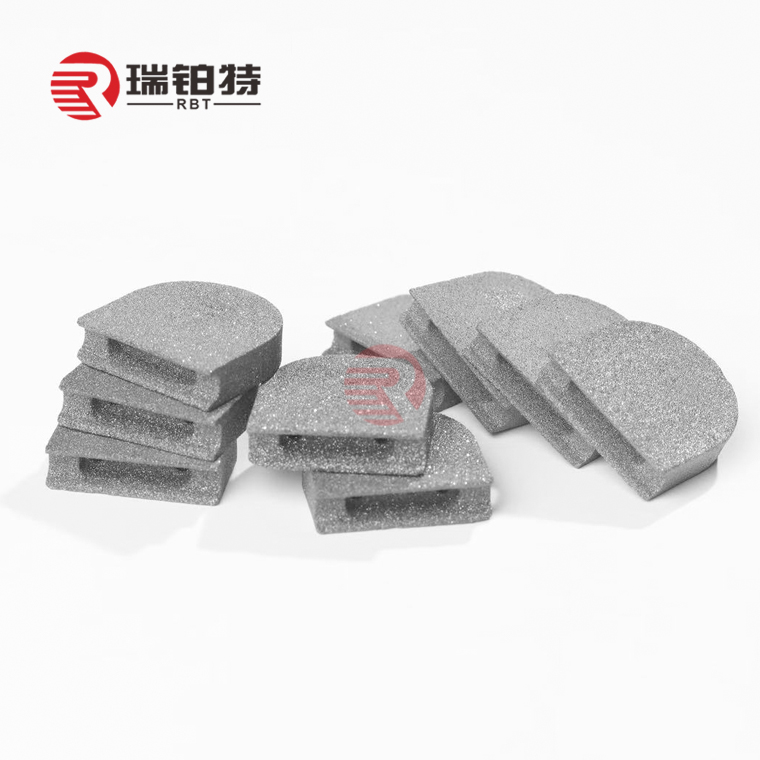

Iinkcukacha Imifanekiso

Umqadi weSilicon Carbide

Iphedi yeSilicon Carbide Cantilever

Impumlo yeSilicon Carbide

Ityhubhu yeSilicon Carbide yokutshisa

Imibhobho yokupholisa yeSilicon Carbide

Impumlo yeSilicon Carbide

Isibiyeli seSilicon Carbide Boat

Ilayini engagugiyo

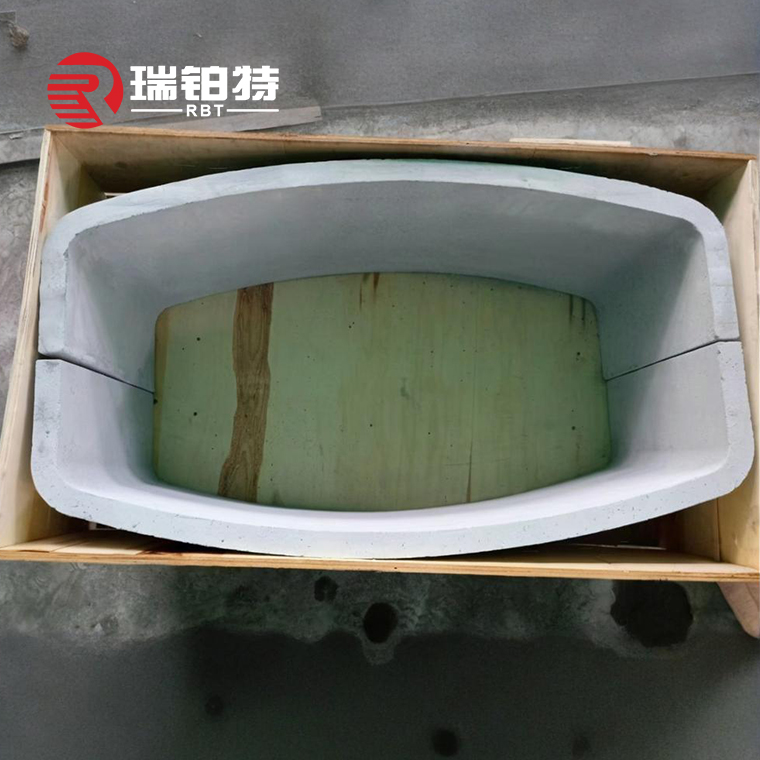

Inqanawa yeSilicon Carbide Wafer

Isalathiso seMveliso

| Iimveliso ze-RBSiC(SiSiC) | ||

| Into | Iyunithi | Idatha |

| Ubushushu obuphezulu besicelo | ℃ | ≤1350 |

| Uxinano | g/cm3 | ≥3.02 |

| I-Porosity evulekileyo | % | ≤0.1 |

| Amandla Okugoba | I-Mpa | 250(20℃); 280(1200℃) |

| Imodulus ye-Elasticity | I-Gpa | 330(20℃); 300(1200℃) |

| Ukuqhuba kweThermal | W/mk | 45 (1200℃) |

| I-Coefficient yoKwandiswa koBushushu | K-1*10-6 | 4.5 |

| Ubunzima bukaMoh | | 9.15 |

| I-Acid Alkaline-Ingenabungozi | | Igqwesile |

2. Iimveliso ze-silicon carbide ezicinezelweyo ezingenaxinzelelo (iimveliso ze-SSiC)

Iimveliso ze-silicon carbide ezisinki ezingenaxinzelelo luhlobo lwezinto zobugcisa obuphezulu ze-ceramic ezilungiselelwe ngenkqubo yokusinki engenaxinzelelo. Icandelo layo eliphambili yi-silicon carbide (SiC), kwaye inani elithile lezongezo zongezwa. Ngobuchwepheshe be-ceramic obuphambili, yenziwa ibe yi-ceramics engenamibhobho, engenamthungo, kwaye engenaxinzelelo.

(1) Iimpawu:

Ukumelana nobushushu obuphezulu:ukusetyenziswa okuqhelekileyo kwi-1800℃;

Ukuqhuba okuphezulu kobushushu:ilingana nokuqhuba kobushushu kwegraphiteizixhobo;

Ubulukhuni obuphezulu:ubulukhuni bulandela idayimani kunye ne-cubic boron nitride kuphela;

Ukumelana nokugqwala:i-asidi enamandla kunye ne-alkali enamandla azinawo umhlwa kuyo, kwaye ukumelana kwayo nomhlwa kungcono kune-tungsten carbide kunye ne-aluminium oxide;

Ubunzima obulula:uxinano 3.10g/cm3, kufutshane ne-aluminium;

Akukho tshintsho:i-coefficient yokwandisa ubushushu encinci kakhulu,

Ayimelani noxinzelelo lobushushu:Izinto ezisetyenzisiweyo zinokumelana notshintsho olukhawulezileyo lobushushu, ukutshayiswa kobushushu, ukupholisa nokufudumeza ngokukhawuleza, kwaye zisebenza kakuhle.

(2) Iimveliso eziphambili:

Amaringi okutywina:Iimveliso ze-silicon carbide ezifakwe i-sinterless sintered zidla ngokusetyenziswa ukuvelisa iiringi zokuvala kunye neebheringi ezityibilikayo ezingagugiyo nezimelana nokugqwala.

Izixhobo zoomatshini:Kubandakanya iibheringi zobushushu obuphezulu, izitywino zoomatshini, ii-nozzles, iivalvu zomoya, imizimba yepompo, izixhobo, njl.njl.

Izixhobo zekhemikhali:Isetyenziselwa ukuvelisa iipayipi ezingamelani nokugqwala, iitanki zokugcina, iireactor kunye nezitywini.

Izixhobo ze-elektroniki:Kwishishini lamandla, i-silicon carbide engenaxinzelelo isetyenziselwa ukuvelisa izithinteli zobushushu obuphezulu, izinto zokufudumeza ngombane kunye neeswitshi ze-voltage ephezulu.

Ifenitshala yekhitshi:Ezifana neefreyimu zesakhiwo ezithwala umthwalo, iirola, ii-nozzles zomlilo, iipayipi zokupholisa, njl.njl. kwii-ovens ze-tunnel, ii-ovens ze-shuttle kunye nezinye ii-ovens zoshishino.

Iinkcukacha Imifanekiso

Indandatho yeTywina leSilicon Carbide

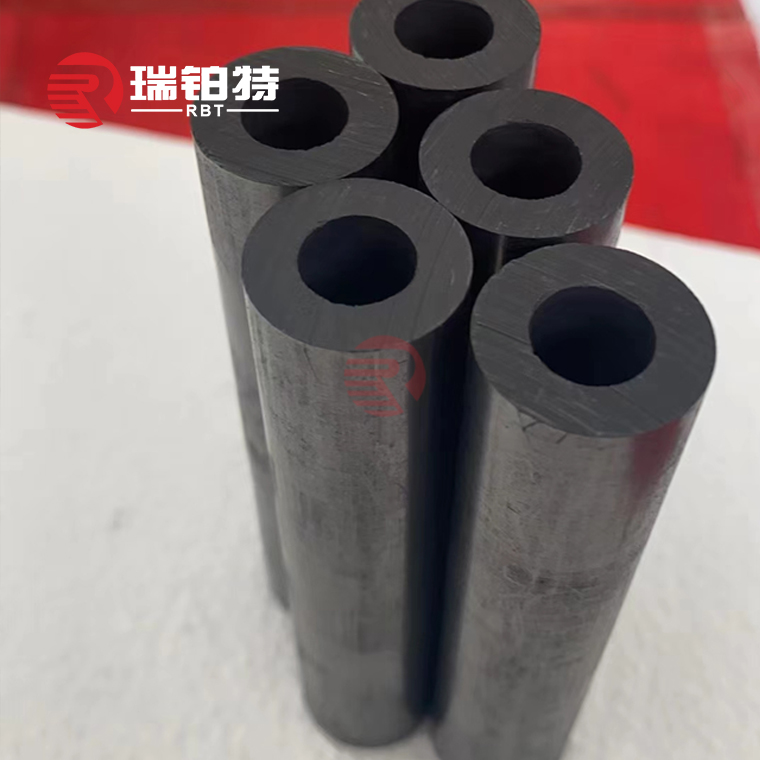

Umbhobho weSilicon Carbide

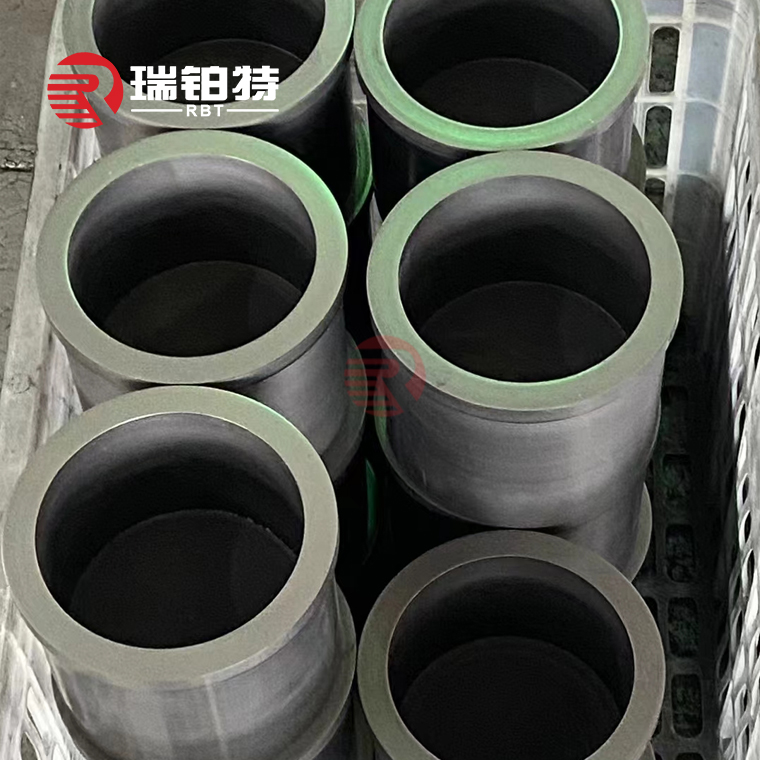

IiLiner zeSilicon Carbide

Umqadi weSilicon Carbide

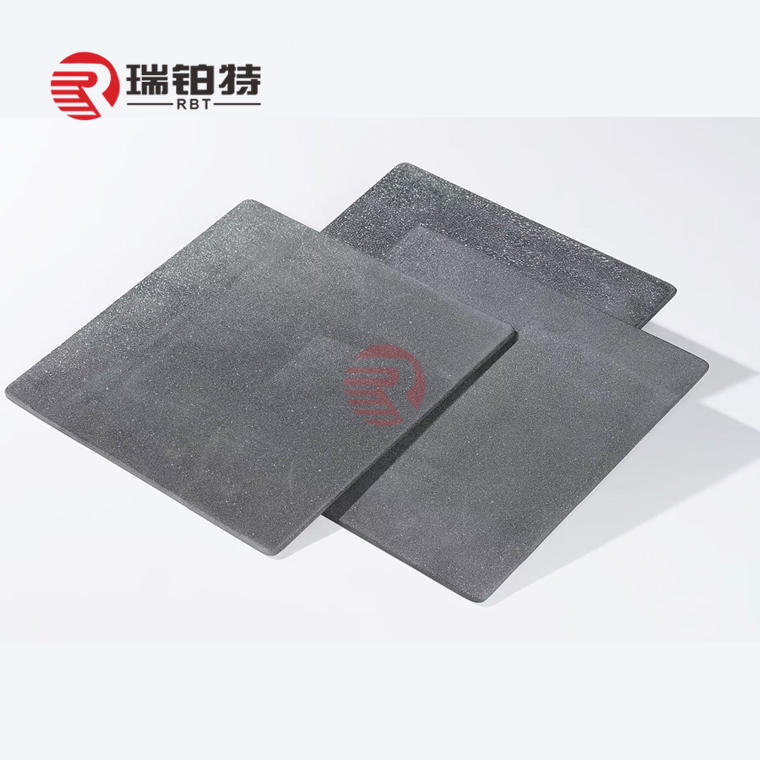

Ipleyiti yeCarbide yeSilicon

Ibhareli Yokugaya yeSilicon Carbide

Isalathiso seMveliso

| Iimveliso ze-SSiC | ||

| Into | Iyunithi | Isiphumo |

| Ukuqina | HS | ≥115 |

| Izinga lokubola | % | <0.2 |

| Uxinano | g/cm3 | ≥3.10 |

| Amandla oxinzelelo | I-Mpa | ≥2500 |

| Amandla Okugoba | I-Mpa | ≥380 |

| Umlinganiselo wokwandisa | 10-6/℃ | 4.2 |

| Umxholo weSiC | % | ≥98 |

| Si yasimahla | % | <1 |

| Imodulus ye-Elastic | I-Gpa | ≥410 |

| Ubushushu obuphezulu besicelo | ℃ | 1400 |

3. Imveliso ye-silicon carbide ephinde yasetyenziswa (iimveliso ze-RSiC)

Iimveliso zeSilicon Carbide eziphinde zasetyenziswa kwakhona yimveliso enganyangekiyo eyenziwe ngesilicon carbide ecocekileyo kakhulu njengezinto eziluhlaza. Uphawu lwayo oluphambili kukuba akukho sigaba sesibini kwaye yenziwe nge-100% α-SiC.

(1) Iimpawu:

Ubunzima obuphezulu:Ubulukhuni bayo bulandela idayimani kuphela, kwaye inamandla aphezulu oomatshini kunye nokuqina kwayo.

Ukumelana nobushushu obuphezulu:Ingagcina ukusebenza okuzinzileyo kwindawo enobushushu obuphezulu kwaye ifanelekile kuluhlu lobushushu oluyi-1350 ~ 1600℃.

Ukumelana nokugqwala okunamandla:Inokumelana nokugqwala okuphezulu kwiindidi ezahlukeneyo zeendaba kwaye iyakwazi ukugcinaiipropati zoomatshini ixesha elide kwiindawo ezahlukeneyo ezirhabaxa.

Ukumelana okuhle kwe-oxidation:Inokumelana okuhle kwe-oxidation kwaye ingasebenza ngokuzinzileyo kumaqondo obushushu aphezulu.

Ukumelana kakuhle nobushushu:Isebenza kakuhle kwindawo enotshintsho olukhawulezileyo lobushushu kwaye ifanelekile kwiindawo ezishushu kakhulu.

Akukho kuncipha ngexesha lokucoca:Ayinciphi ngexesha lenkqubo yokusila, kwaye akukho xinzelelo olushiyekileyo oluya kuvela oluya kubangela ukuguquka okanye ukuqhekeka kwemveliso. Ifanelekile ukulungiselela iindawo ezineemilo ezintsonkothileyo kunye nokuchaneka okuphezulu.

(2) Iimveliso eziphambili:

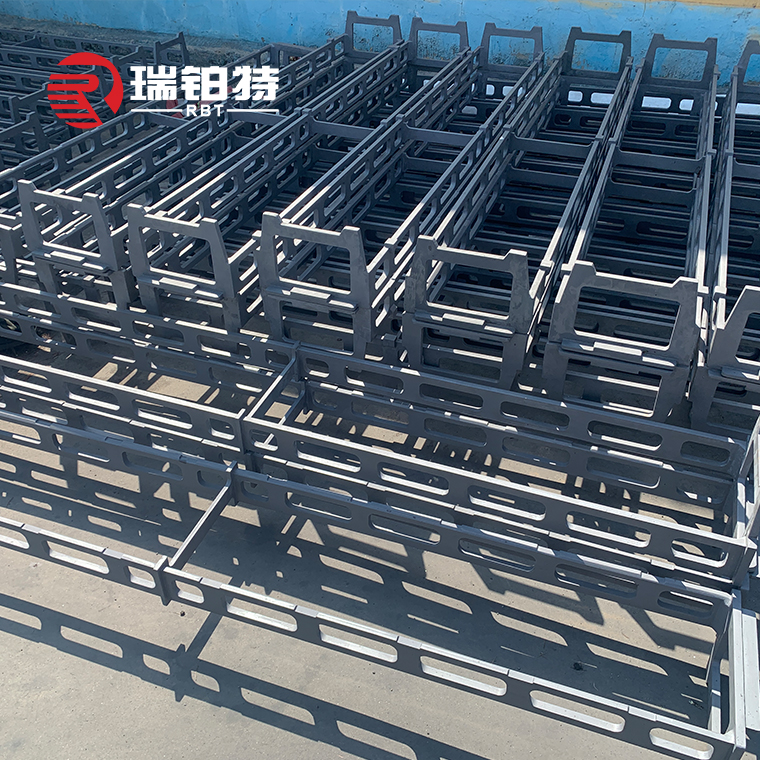

Izinto zefenitshala ye-kiln:Isetyenziswa kakhulu kwifenitshala ye-oven, ineengenelo zokonga amandla, inyusa umthamo osebenzayo we-oven, inciphisa umjikelo wokudubula, iphucula ukusebenza kakuhle kwemveliso ye-oven kunye neenzuzo eziphezulu zoqoqosho.

Ii-nozzles ze-bunner:Ingasetyenziswa njengeentloko zomlomo wokutshisa kwaye ifanelekile kwiindawo ezinobushushu obuphezulu.

Iityhubhu zokufudumeza ngemisebe yeseramikhi:Ezi tyhubhu zokufudumeza zisebenzisa ithuba lokuzinza kobushushu obuphezulu kunye nokumelana nokugqwala kwe-silicon carbide ephinde yasetyenziswa kwaye zifanelekile kwiindlela ezahlukeneyo zokusetyenziswa kwemizi-mveliso ezinobushushu obuphezulu.

Iityhubhu zokukhusela izinto:Ingakumbi kwiifeni zomoya, iimveliso ze-silicon carbide eziphinde zasetyenziswa zisetyenziswa njengeetyhubhu zokukhusela izinto ezinobushushu obuphezulu obuhle kunye nokumelana nokugqwala.

Imizimba yempompo enobushushu obuphezulu, ii-impellers zempompo, iibheringi, iindawo zenjini:Kwimimandla yeemoto, i-aerospace kunye nemizi-mveliso yomkhosi, izixhobo ze-silicon carbide eziphinde zasetyenziswa zenziwa zibe zii-pump bodies ezinobushushu obuphezulu, ii-pump impellers, ii-bearings kunye nee-injini housing, njl.njl., zisebenzisa ithuba lokumelana nobushushu obuphezulu, ukumelana nokugqwala kwe-asidi kunye ne-alkali kunye nokumelana nokuguguleka.

Iinkcukacha Imifanekiso

Iinxalenye eziMile ngeSilicon Carbide

Ipleyiti yeCarbide yeSilicon

Irola yeSilicon Carbide

Umqadi weSilicon Carbide

Iityhubhu zoKhuseleko lweSilicon Carbide

Ifenitshala yeKiln

I-Silicon Carbide Sagger

Isiqhoboshi seSilicon Carbide

Ipleyiti yeCarbide yeSilicon

I-Lgniter yeSilicon Carbide

Umbhobho weSilicon Carbide

Isitshisi seSilicon Carbide

4. Iimveliso ze-silicon carbide ezibotshelelweyo ze-silicon nitride (iiMveliso ze-NSiC)

Iimveliso ze-silicon carbide ezibotshelelweyo ze-silicon nitride ziyimpahla eyenziwe ngokongeza i-SiC aggregate kwi-industrial silicon powder, isabela ne-nitrogen kubushushu obuphezulu ukuvelisa i-Si3N4 kwaye idityaniswe ngokuqinileyo namasuntswana e-SiC.

(1) Iimpawu:

Ubunzima obuphezulu:Ubunzima beMohs beemveliso zesilicon carbide ezibotshelelweyo zesilicon nitride bumalunga ne-9, bulandela idayimani kuphela, kwaye buyinto enobunzima obuphezulu phakathi kwezinto ezingezizo ezesinyithi.

Amandla aphezulu obushushu:Kumaqondo obushushu aphezulu angama-1200-1400℃, amandla kunye nobunzima bezinto azitshintshi phantse, kwaye ubushushu obuphezulu bokusetyenziswa obukhuselekileyo bunokufikelela kwi-1650-1750℃.

Uzinzo lobushushu:Ine-coefficient encinci yokwandisa ubushushu kunye nokuqhuba okuphezulu kobushushu, akulula ukuvelisa uxinzelelo lobushushu, izinzile kakuhle kwi-thermal shock kunye nokumelana nokuqhekeka, kwaye ifanelekile kwiindawo ezibandayo kakhulu nezishushu kakhulu.

Uzinzo lweekhemikhali:Ayinakumelana nokugqwala kwaye ayitshisi ioksijini, kwaye inokuhlala izinzile kwiindawo ezahlukeneyo zeekhemikhali.

Ukumelana nokunxitywa:Inokumelana nokuguguleka okuhle kwaye ifanelekile kwiindlela ezahlukeneyo zokusebenza kwimizi-mveliso kunye nokuguguleka okukhulu.

(2) Iimveliso eziphambili:

Izitena ezirhabaxa:Isetyenziswa kakhulu kwi-aluminium ye-electrolytic, kwii-ironmaking blast furnitures, kwii-indened arc furnitures nakwamanye amashishini, kunye neempawu zokuxhathisa amaqondo obushushu aphezulu, ukuxhathisa ukugqwala, kunye nokuxhathisa ukukhukuliseka.

Ifenitshala yesitovu:isetyenziselwa amavili okugaya e-ceramic, i-porcelain yombane ene-voltage ephezulu, ii-oven zemizi-mveliso, njl.njl., ezinomthamo olungileyo wokuthwala umthwalo kunye nokumelana nobushushu obuphezulu.

Iimveliso ezimile ngendlela ekhethekileyo:isetyenziswa kwi-casting ye-metallurgical engena-ferrous, amandla obushushu, ii-arc furnace kunye nezinye iimboni, kunye neempawu zokumelana nokuguguleka kunye nokumelana nobushushu obuphezulu.

Iindawo ezirhabaxa:kuquka iityhubhu zokukhusela i-thermocouple, iityhubhu zokuphakamisa, ii-heating sleeves, njl.njl., ezisetyenziswa kwii-ovens ezinobushushu obuphezulu kunye nee-atmospheres ezahlukeneyo, ezinomoya ophezulu wokuqhuba ubushushu kunye nokumelana nokugqwala.

Iinkcukacha Imifanekiso

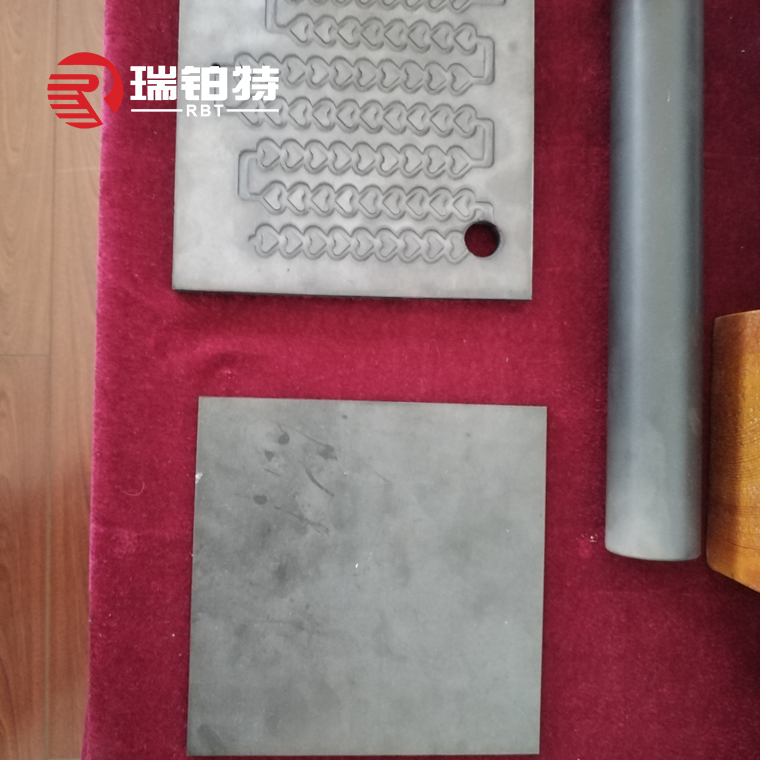

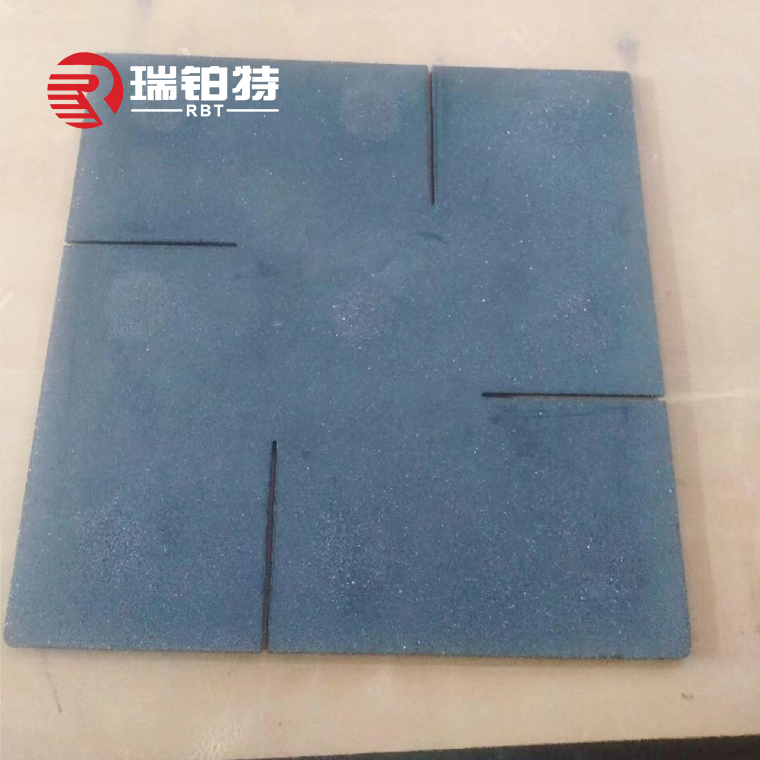

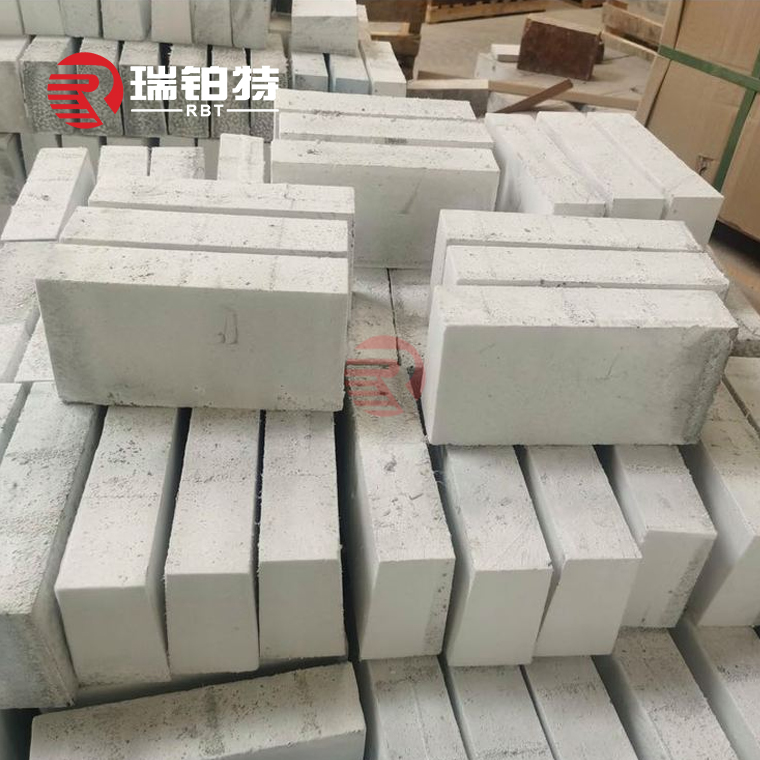

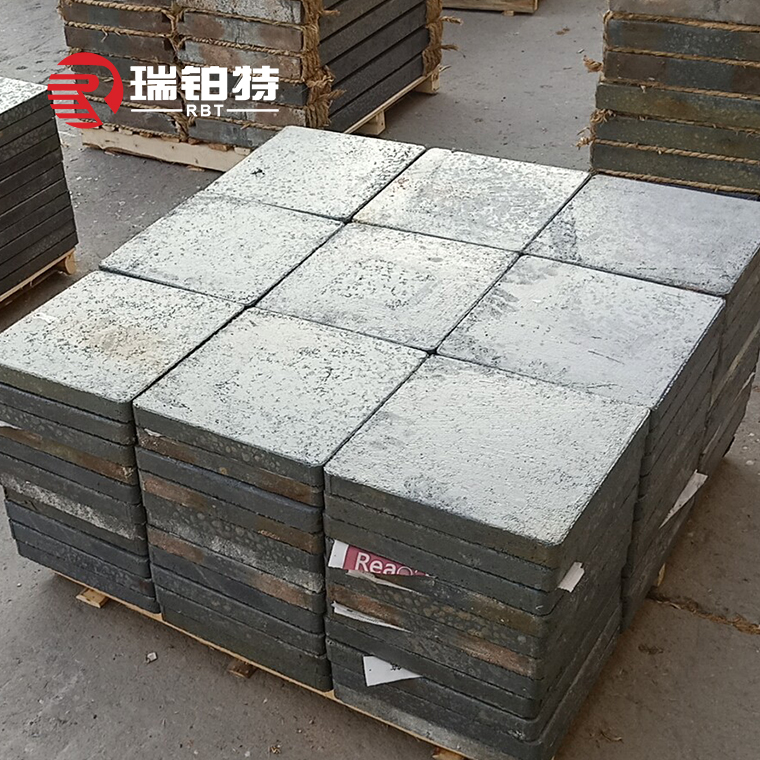

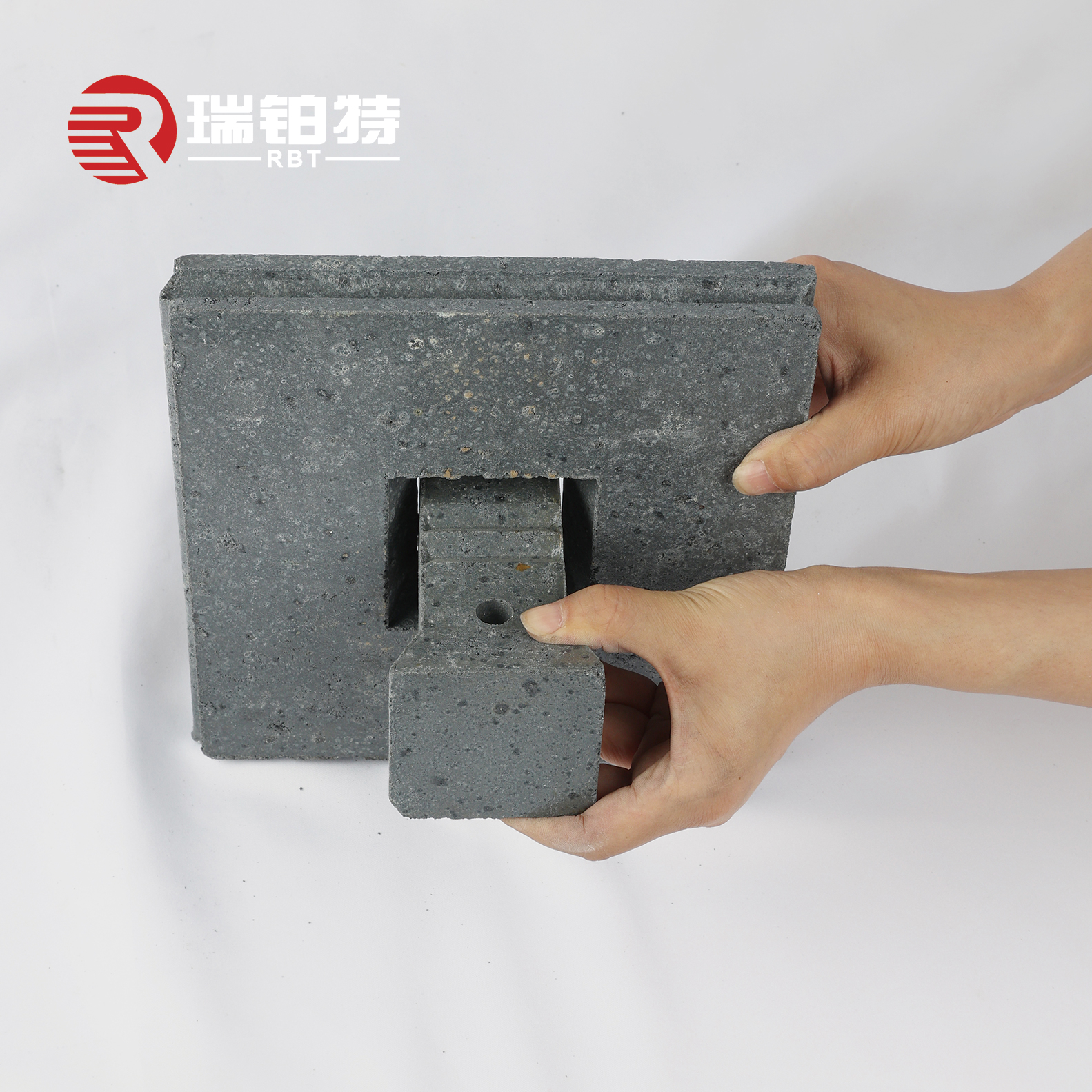

Ipleyiti Enemilo yeSilicon Carbide

Ipleyiti Enemilo yeSilicon Carbide

Ipleyiti Enemilo yeSilicon Carbide

Ipleyiti Enemilo yeSilicon Carbide

Ipleyiti Enemilo yeSilicon Carbide

Iityhubhu zemisebe yeSilicon Carbide

Umbhobho weSilicon Carbide

Ipleyiti Enemilo yeSilicon Carbide

Iinxalenye eziMile ngeSilicon Carbide

Iityhubhu zoKhuseleko lweSilicon Carbide

Ipleyiti yeCarbide yeSilicon

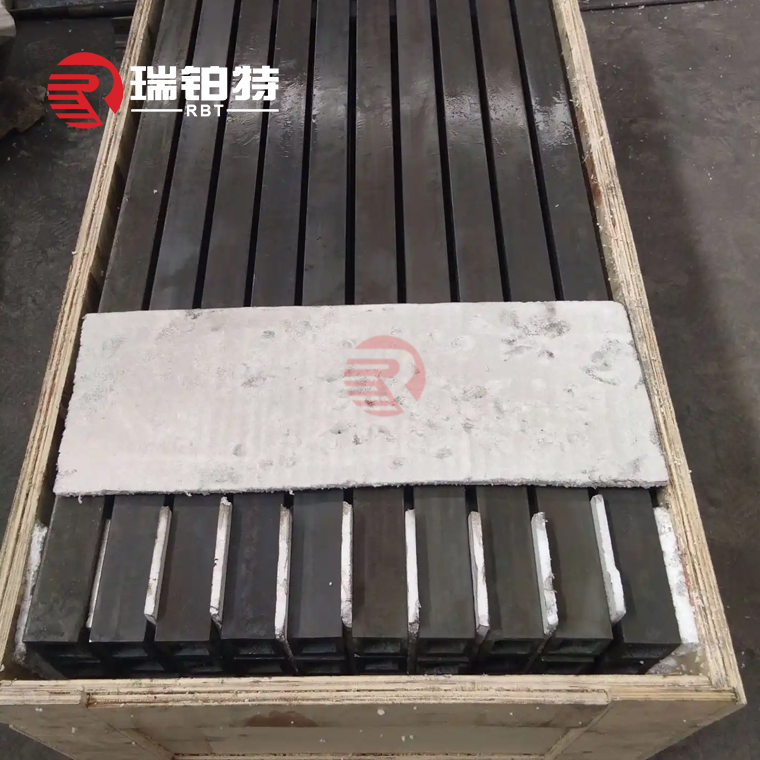

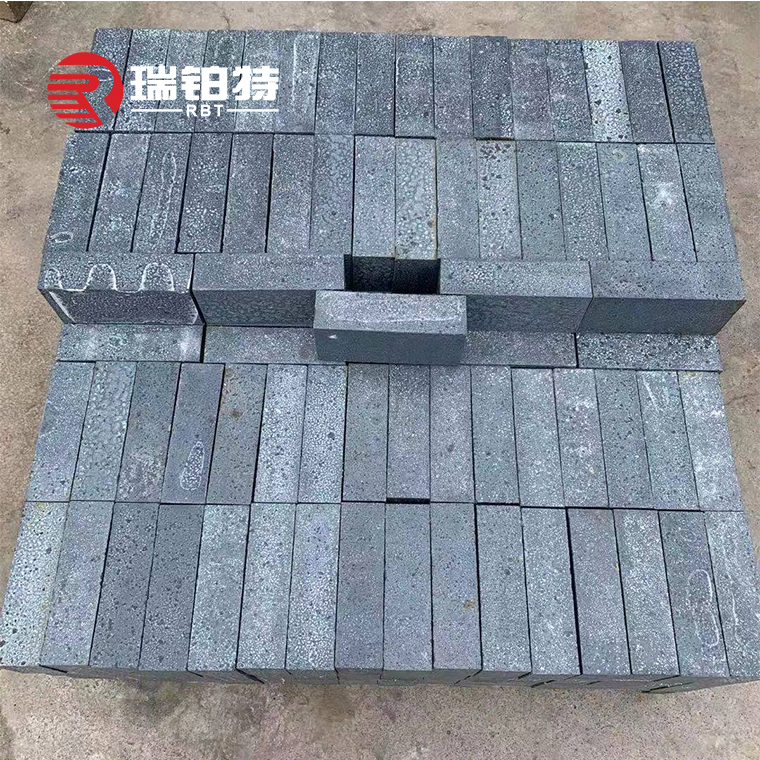

Izitena zeSilicon Carbide

5. Iimveliso ze-silicon carbide ezibotshelelwe kwi-oxide

Iimveliso ze-silicon carbide ezibotshelelwe kwi-oxide zenziwa ngokuxuba amasuntswana e-silicon carbide kunye nomgubo we-oxide (njenge-silicon dioxide okanye i-mullite), ukucinezela kunye nokusila kubushushu obuphezulu. Uphawu lwayo kukuba ngexesha lenkqubo yokusila nokusetyenziswa, ifilimu ye-oxide isongelwa kumasuntswana e-silicon carbide, nto leyo ephucula kakhulu ukumelana ne-oxidation kunye namandla obushushu aphezulu.

Ineempawu zokuba namandla aphezulu okugoba kwiqondo lobushushu eliphezulu, uzinzo oluhle lokutshona kobushushu, ukuqhuba kobushushu okuphezulu, ukumelana nokuguguleka kunye nokumelana okukhulu nokukhukuliseka komoya okwahlukeneyo, kwaye sisixhobo esifanelekileyo sokonga amandla kwiifeni zoshishino.

(2) Iimveliso eziphambili:

Iimveliso ze-silicon carbide ezibophelelwe yi-silicon dioxide:Le mveliso isebenzisa i-silicon dioxide (SiO2) njengesigaba sokubopha. Ngokwesiqhelo i-5% ~ 10% yomgubo we-silicon dioxide okanye umgubo we-quartz ixutywa namasuntswana e-silicon carbide (SiC). Ngamanye amaxesha kongezwa i-flux. Emva kokucinezela nokwenziwa, itshiswa kwi-oven eqhelekileyo. Uphawu lwayo kukuba ngexesha lokudubula nokusetyenziswa, ifilimu ye-silicon dioxide isongelwe kumasuntswana e-silicon carbide, nto leyo ephucula kakhulu ukumelana ne-oxidation kunye namandla obushushu aphezulu. Le mveliso isetyenziswa kakhulu kwiishelufu ze-oven zokutshisa i-porcelain (>1300℃), kwaye ubomi bayo benkonzo bungaphezulu

iphindwe kabini kuneemveliso ze-silicon carbide ezibotshelelwe ngodongwe.

Iimveliso ze-silicon carbide ezibophelelweyo ezininzi:Le mveliso yongeza umgubo we-α-Al2O3 kunye nomgubo we-silicon dioxide kwizithako ze-silicon carbide. Emva kokucinezela nokwenziwa, i-Al2O3 kunye ne-SiO2 zidityaniswe ukwenza i-mullite ngexesha lenkqubo yokusila. Ngexesha lokusetyenziswa, i-silicon dioxide eyenziwe yi-oxidation ye-silicon carbide yenza i-mullite ngenxalenye ye-Al2O3. Le nto inozinzo oluhle lobushushu kwaye isetyenziswa kakhulu ekwenzeni ii-porcelain saggers kunye neeshelufu.

Iinkcukacha Imifanekiso

Ipleyiti yeCarbide yeSilicon

Izitena zeSilicon Carbide

Ipleyiti yeCarbide yeSilicon

Umbhobho we-SiC Microcrystalline

Ibhodi ye-SiC Microcrystalline

Ibhodi ye-SiC Microcrystalline

Iprofayile yekhampani

I-Shandong Robert New Material Co., Ltd.ikwiSixeko saseZibo, kwiPhondo laseShandong, eTshayina, elisisiseko semveliso yezinto ezinganyangekiyo. Silishishini lanamhlanje elidibanisa uphando nophuhliso, imveliso, ukuthengisa, uyilo lwe-oven kunye nolwakhiwo, iteknoloji, kunye nezixhobo ezinganyangekiyo ezithunyelwa kwamanye amazwe. Sinezixhobo ezipheleleyo, iteknoloji ephucukileyo, amandla obuchwephesha aqinileyo, umgangatho wemveliso ogqwesileyo, kunye nodumo oluhle. Umzi-mveliso wethu ugubungela iihektare ezingaphezu kwama-200 kwaye imveliso yonyaka yezixhobo ezinganyangekiyo ezimile imalunga neetoni ezingama-30000 kwaye izinto ezinganyangekiyo ezimile ziitoni ezili-12000.

Iimveliso zethu eziphambili zezinto ezichasene ne-refractory ziquka:izixhobo zokuchasana ne-alkaline; izixhobo zokuchasana ne-silicon ye-aluminium; izixhobo zokuchasana ezingamiliyo; izixhobo zokuchasana ne-thermal insulation; izixhobo ezikhethekileyo zokuchasana ne-refractory; izixhobo zokuchasana ezisebenzayo kwiinkqubo zokuphosa eziqhubekayo.

Imibuzo ebuzwa qho

Ngaba ufuna uncedo? Qiniseka ukuba undwendwela iiforam zethu zenkxaso ukuze ufumane iimpendulo kwimibuzo yakho!

Singumvelisi wokwenyani, umzi-mveliso wethu ugxile ekuveliseni izinto ezichasene nendalo kangangeminyaka engaphezu kwama-30. Sithembisa ukubonelela ngexabiso elifanelekileyo, eyona nkonzo ingcono ngaphambi kokuthengisa nasemva kokuthengisa.

Kwinkqubo nganye yemveliso, i-RBT inenkqubo epheleleyo ye-QC yokwakheka kweekhemikhali kunye neempawu zomzimba. Kwaye siza kuvavanya iimpahla, kwaye isiqinisekiso somgangatho siya kuthunyelwa kunye neempahla. Ukuba uneemfuno ezizodwa, siza kuzama konke okusemandleni ethu ukuzilungiselela.

Ngokuxhomekeke kubungakanani, ixesha lethu lokuhambisa lahlukile. Kodwa sithembisa ukuthumela ngokukhawuleza kangangoko kunokwenzeka ngomgangatho oqinisekisiweyo.

Kakade ke, sinikezela ngeesampuli zasimahla.

Ewe, ewe, wamkelekile ukutyelela inkampani ye-RBT kunye neemveliso zethu.

Akukho mda, singakunika ingcebiso nesisombululo esifanelekileyo ngokwemeko yakho.

Besisenza izinto ezirhabaxa kangangeminyaka engaphezu kwama-30, sinenkxaso yobugcisa enamandla kunye namava amaninzi, singanceda abathengi ukuba bayile ii-kiln ezahlukeneyo kwaye banikezele ngenkonzo enye.