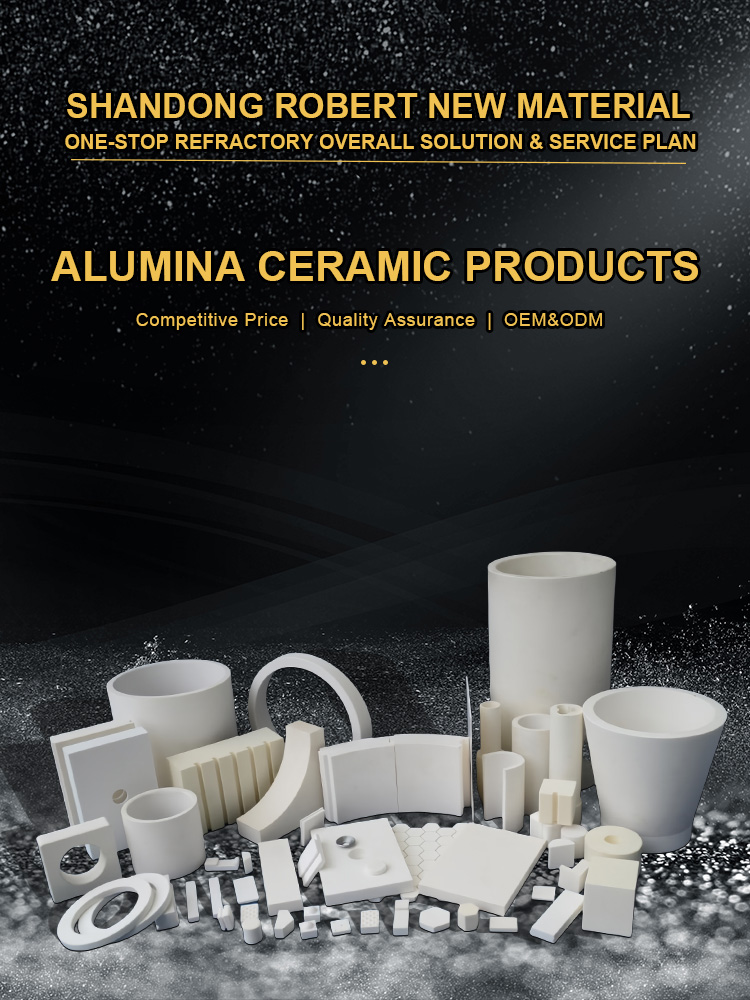

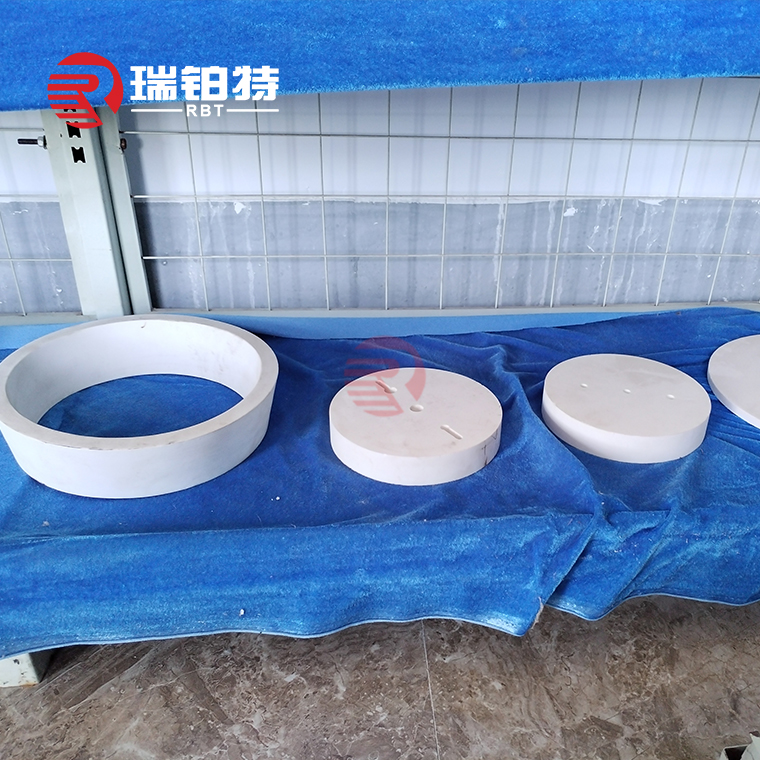

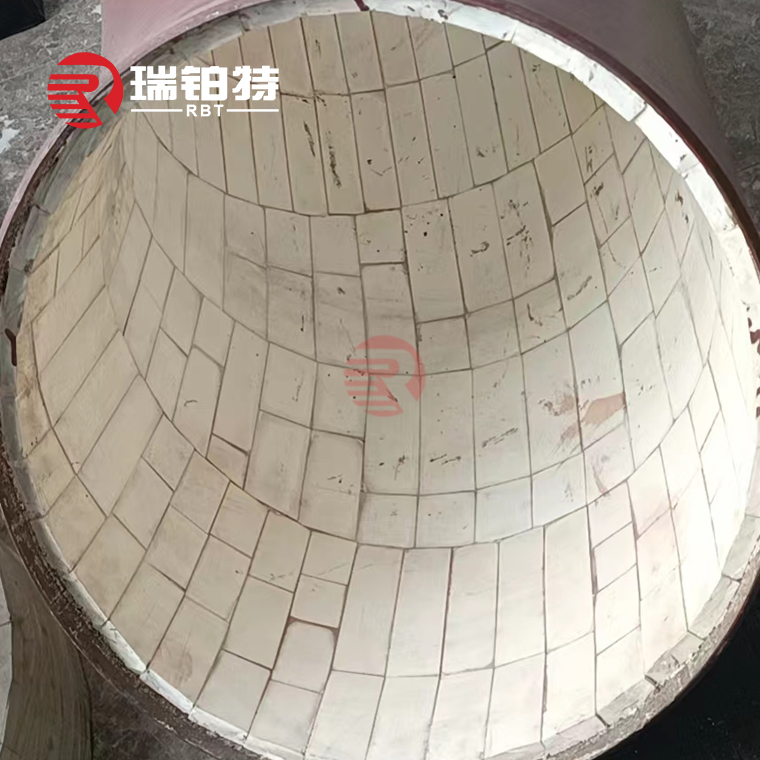

Iipleyiti zeAlumina zeLining

Ikhathalogu yeMveliso

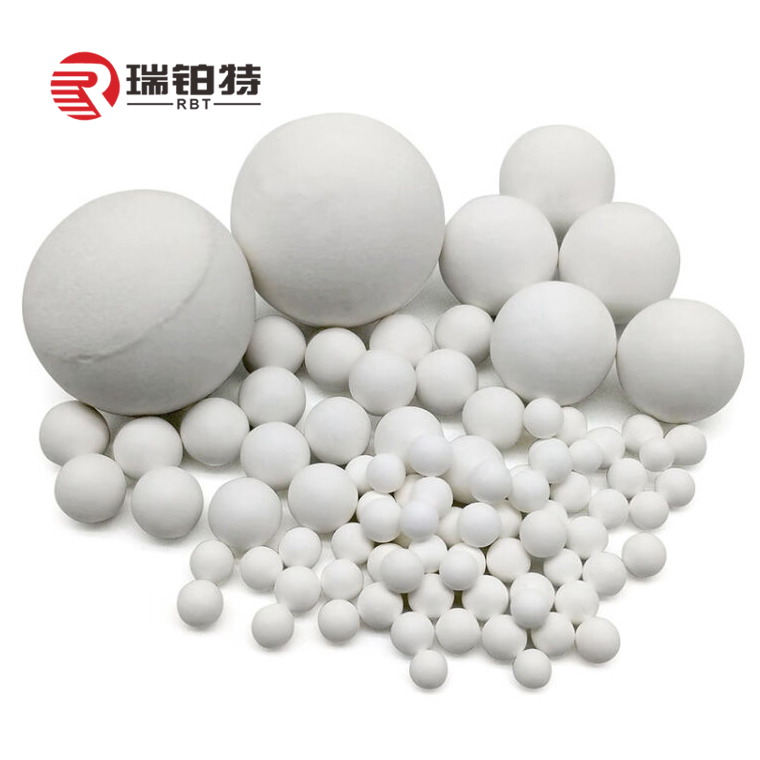

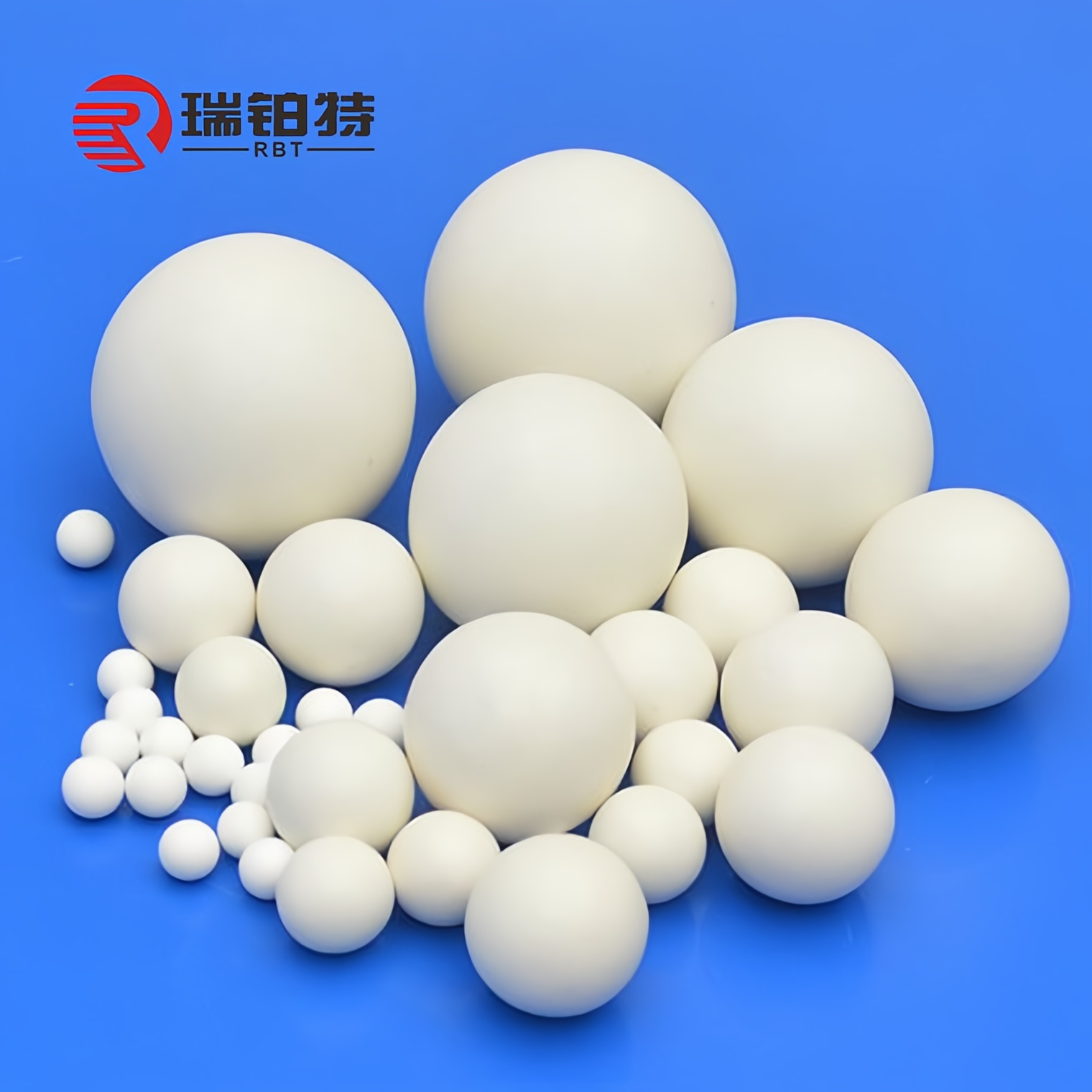

1. Ibhola yeAlumina

(1) Iibhola ze-alumina ceramiczizinto eziphathekayo eziphezulu ze-inorganic non-metallic kunye ne-aluminium oxide (Al2O3) njengeyona nto iphambili.

Iimbonakalo:

Ukumelana nokunxiba okuphezulu; Ukumelana nobushushu obuphezulu; Ukumelana nokubola; Ubunzima obukhulu; Amandla aphezulu oxinzelelo; Uzinzo oluhle lwe-thermal

Isicelo:

Inkxaso ye-Catalyst kunye ne-tower filler:Kwi-reactor, iibhola ze-alumina ceramic zisetyenziswa njenge-catalyst yokugquma izixhobo zenkxaso kunye nezihluzi zenqaba ukunyusa iindawo zokuhambisa igesi okanye ulwelo ukuphucula ukusebenza kakuhle kokusabela kunye nokukhusela i-catalyst esebenzayo ngamandla aphantsi. ...

Imidiya yokucola:Isetyenziswa kakhulu kwisixhobo sokusila esicolekileyo njengeebhola zokusila kunye ne-vibration Mills ukucola intsimbi ekrwada, i-slurries, imathiriyeli engagugiyo, kunye nomgubo onje ngeecoat kunye neepeyinti. Ukumelana nokunxiba kwayo okugqwesileyo kunye nokujikeleza kwayo kunokunqanda imikrwelo ngexesha lokupolishwa kunye nokunxibelelana ngokupheleleyo nento yokupolisha. ...

Ezinye izicelo:Ikwasetyenziswa ngokubanzi kumashishini amaninzi anje ngepetrochemicals, ukwakha iiseramikhi zococeko, iiminerali ezingezizo ezentsimbi, intsimbi kunye ne-elektroniki.

...(2) I-alumina yokusila ibholaluhlobo lwesixhobo sokusila esenziwe nge-bauxite, umgubo we-roller, umgubo we-alumina kwishishini, njl. Icandelo layo eliphambili yi-α-Al2O3, eneempawu zobunzima obuphezulu, ukuxhatshazwa okuphezulu kokugqoka kunye nokuzinza kweekhemikhali, kwaye isetyenziswa ngokubanzi kwiinkqubo ezahlukeneyo zokusila kunye nokupholisha.

Isicelo:

Umzi-mveliso weCeramic kunye neglasi:esetyenziselwa ukugaya i-glaze kunye ne-ceramic powder ukuphucula ukufana kunye nokugqiba kwemveliso. ...

Ishishini lokugquma:isetyenziselwa ukugaya kunye nokusabalalisa iingubo ezisekelwe kumanzi kunye ne-oyile ukuze kuphuculwe ubumanzi kunye nokubambelela kweengubo. ...

Ishishini le-elektroniki:isetyenziselwa ukugaya iindawo ezichanekileyo zoomatshini kunye nezinto ezibonakalayo zokuqinisekisa ukuchaneka okuphezulu kunye nomgangatho olungileyo womphezulu. ...

Imathiriyeli yamandla amatsha:esetyenziselwa ukugaya izinto zebhetri ye-lithium ukukhuthaza ukuhanjiswa okufanayo kunye nokuphucula ukusebenza kwezinto. Ukhuseleko lokusingqongileyo: isetyenziselwa ukucocwa kwamanzi amdaka kunye nokuphelelwa ngamanzi kwe-sludge ukususa ukungcola kunye nongcoliseko emanzini.

Uluhlu lobungakanani besuntswana:0.3-0.4, 0.4-0.6, 0.6-0.8, 0.8-1.0, 1.0-1.2, 1.2-1.4, 1.4-1.6, 1.8-2.0, 2.0-2.2, 2.2-2.4, 2.8-3, 3.5. 4.5-5.0, 5.0-5.5, 6.0-6.5, 6.5-7.0, 8, 10, 12, 15, 20

Iibhola zokuSila zeAlumina

Iibhola zeCeramic zeAlumina

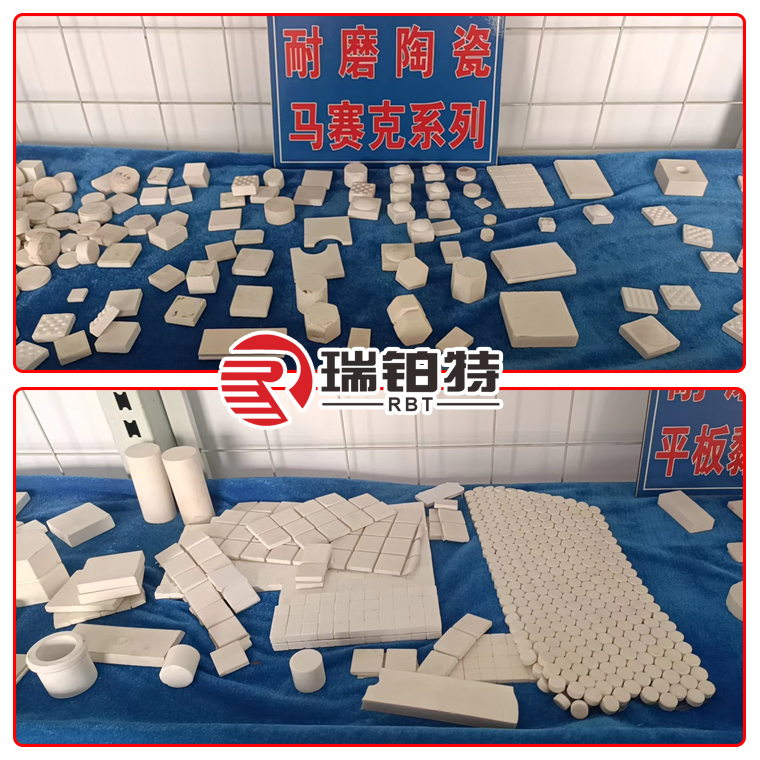

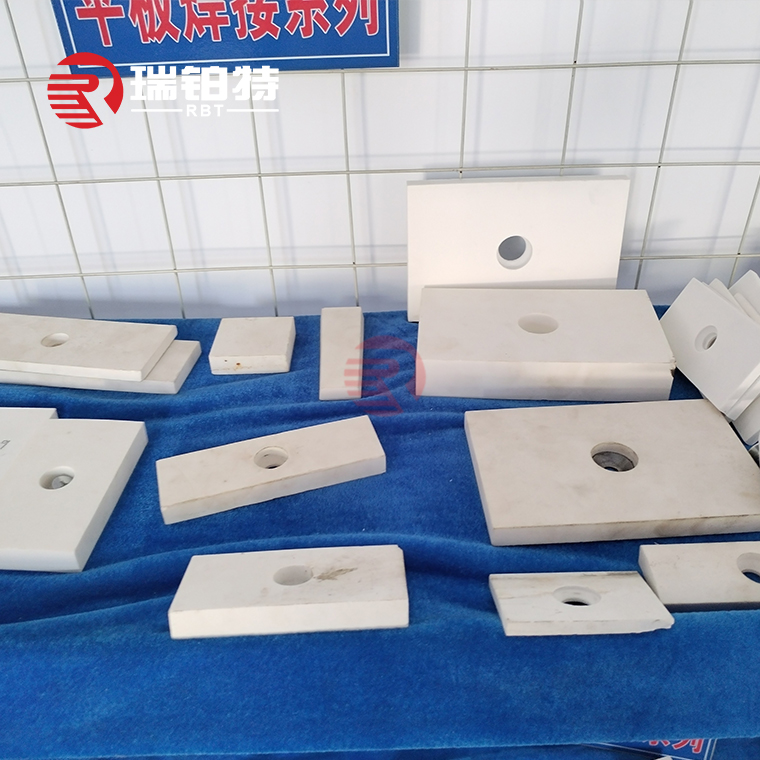

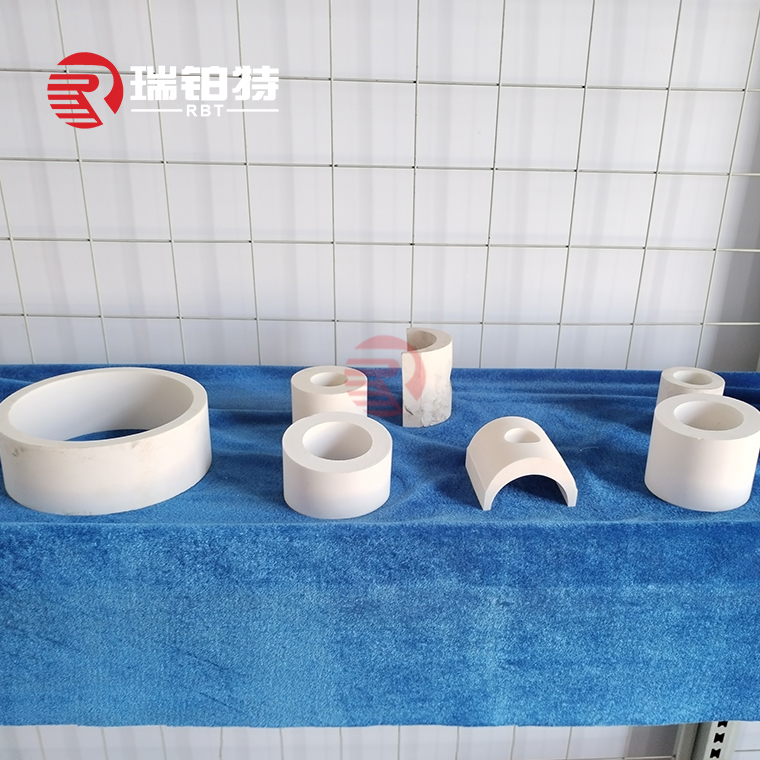

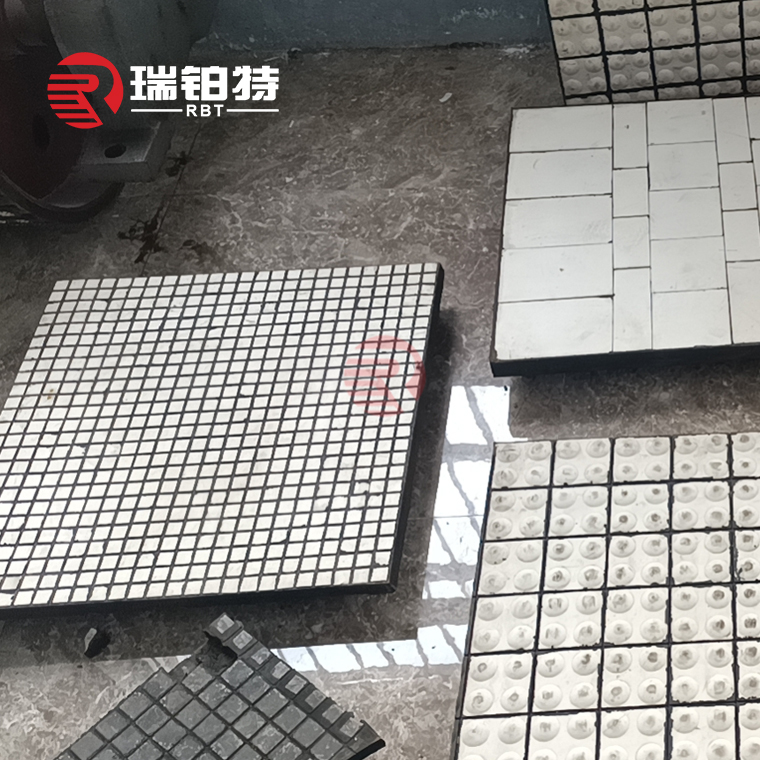

2. 92%, 95% Alumina-resistant iiCeramics(imveliso eqhelekileyo, imilo ekhethekileyo, eyenzelwe wena)

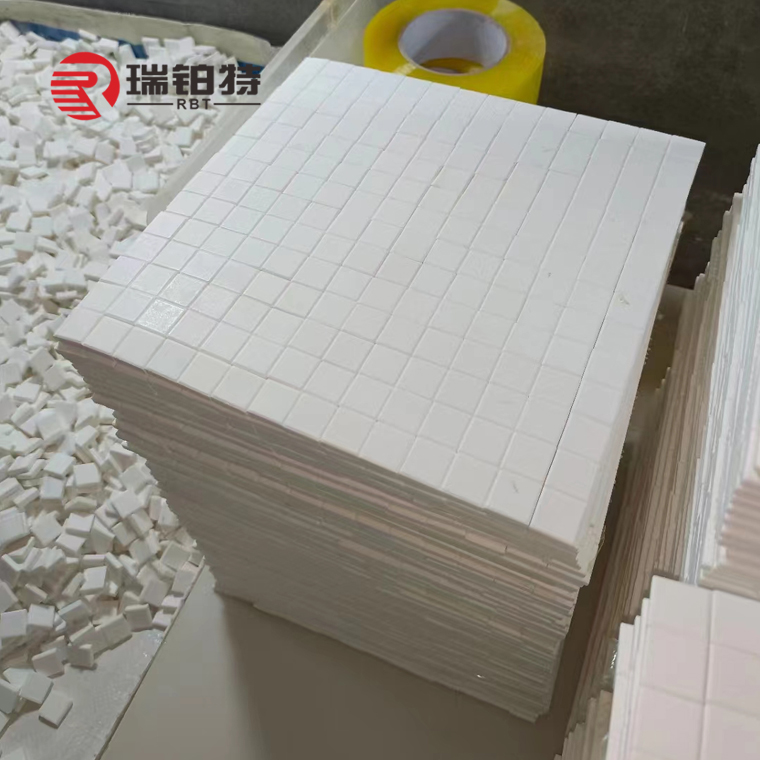

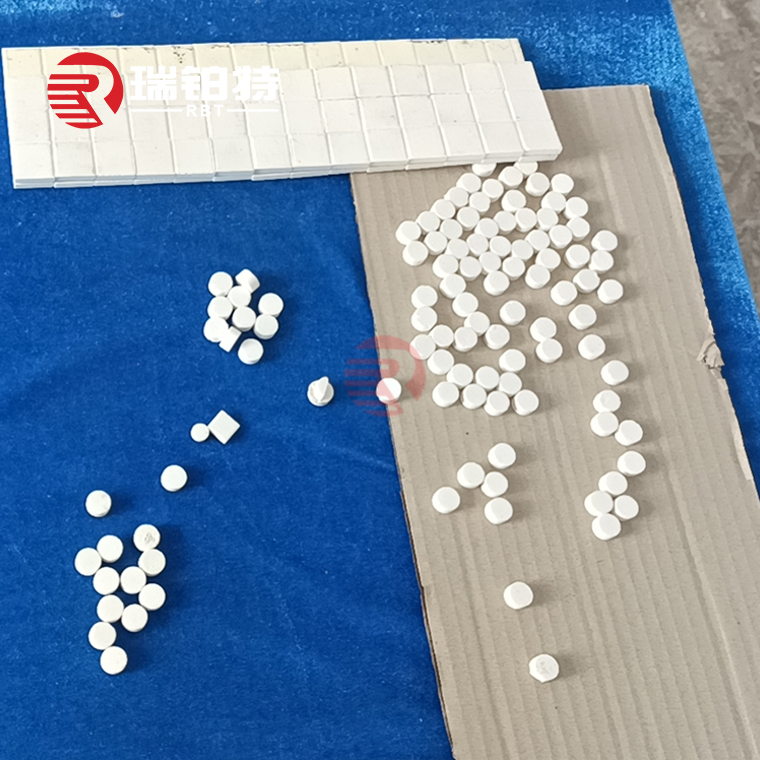

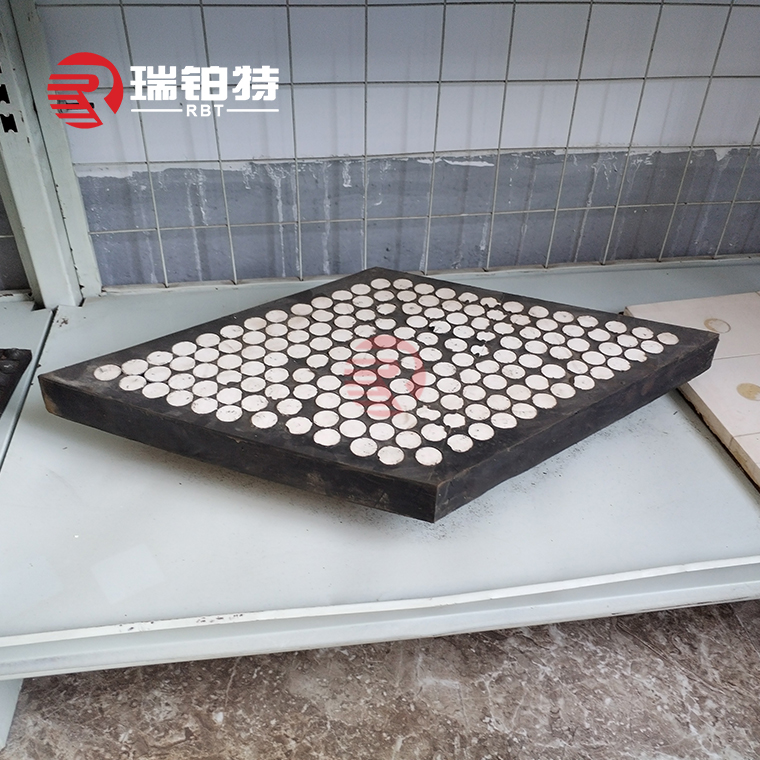

(1) I-ceramic mosaic ekwaziyo ukunxitywa iithayileyimathiriyeli yeceramic esebenza kakhulu, eyenziwe ikakhulu ngezinto zokuqina eziphezulu ze-ceramic ezifana ne-alumina kunye ne-silicon nitride. Umphezulu uphathwa ngeenkqubo ezikhethekileyo kwaye unobunzima obuphezulu kakhulu kunye nokumelana nokugqoka. Inkqubo yokwenziwa kwayo ibandakanya itekhnoloji ephezulu efana nokucinezela okomileyo kunye ne-grouting, kwaye iinkcukacha zahlukile

ukuhlangabezana neemfuno zezicelo zamashishini ezahlukeneyo.

Iimbonakalo:

1. Ukuqina okuphezulu:Ukuqina kwe-Rockwell ye-ceramic mosaic engagungqiyo kufikelela kwi-HRA80-90, okwesibini kuphela kwidayimane, kwaye inobunzima obuphezulu kakhulu kunye nokunganyangeki kokunxiba.

2. Ukumelana nokunxiba:Ukumelana kwayo nokunxiba kufana namaxesha angama-266 ensimbi ye-manganese kunye namaxesha angama-171.5 entsimbi ephezulu ye-chromium, ebonisa ukumelana nokunxiba.

3. Ubunzima obulula:Uxinzelelo yi-3.6g/cm³, esisiqingatha kuphela sentsimbi, enokunciphisa kakhulu umthwalo wesixhobo kunye nokuphucula ukusebenza kakuhle kwesixhobo.

4. Ulwakhiwo olufanelekileyo:I-mosaic ye-ceramic engagungqiyo kulula ukuyifaka kunye nokugcina, ukunciphisa ubunzima kunye neendleko zokwakha.

Isicelo:

Ishishini lePetrochemical:isetyenziswe njengeenxalenye ze-lining kunye ne-resistant-resistant kwi-reactors, imibhobho, imizimba yepompo kunye nezinye izixhobo, ukwandisa kakhulu ubomi bezixhobo kunye nokuphucula ukhuseleko.

Imigodi kunye nesinyithi:iphucula kakhulu ukumelana nokunxiba kunye nokusebenza kakuhle kwemveliso kwiindawo zokunxiba zeizixhobo ezifana neebhola zebhola, izixhobo zamalahle, kunye noomatshini bokutsala. ...

Ishishini lamandla ombane:isetyenziswe kwiindawo ezikwazi ukumelana nombane owenziwe ngamalahle, ukuveliswa kwamandla egesi kunye nezinye izixhobo, ezifana nezitshisi, amalahle, kunye nabaqokeleli bothuli, ukuphucula ngokufanelekileyo ubomi benkonzo kunye nokusebenza kakuhle kwezixhobo. ...

Ukwenziwa koomatshini:esetyenziselwa ukuvelisa iindawo ezichanekileyo, eziphezulu zokunxiba, ezifana neebheringi, iigiya, kunye neentsimbi zesikhokelo, ukuphucula kakhulu ukusebenza kunye nokuthembeka kweemveliso zoomatshini.

(2) Izitena ze-ceramic ezingagugiyongokuqhelekileyo zenziwe ngezinto ezidibeneyo ze-ceramic kunye nezixhobo ze-matrix. Izinto ze-ceramic ngokubanzi zisebenzisa i-alumina ceramics ephezulu okanye i-zirconia ceramics, enokumelana okugqwesileyo kokunxiba kunye namandla oxinzelelo. Izinto ze-matrix ngokuqhelekileyo ziyintsimbi okanye ezinye izinto zetsimbi, ezibonelela ngenkxaso efunekayo kunye nokuqina. Ngokudibanisa i-ceramic layer kunye ne-metal matrix, i-composite material enganyangekiyo kwaye inzima ngokwaneleyo yenziwe.

Isicelo:

Oomatshini basemigodini:Khusela izixhobo zokutyumza kunye nokuhlola kwimpembelelo yentsimbi. ...

Ishishini leMetallurgical:Isetyenziswa kwiziko lobushushu obuphezulu kunye nezixhobo zokuphosa ngenxa yokumelana nobushushu obuphezulu kunye nokumelana nokugqwala. ...

Ishishini lamandla:Isetyenziselwa ukukhusela iinkqubo zokuhambisa umgubo wamalahle kunye neziko kwibhoyila. ...

Ukuveliswa kwesamente:Nciphisa uqhagamshelwano oluthe ngqo phakathi kwamabhanti okuhambisa kunye nezixhobo kunye nokwandisa ubomi bezixhobo. ...

Ishishini lemichiza:Isetyenziswe kwizixhobo ezifana neebhola zebhola ukunyusa imveliso yokugaya kunye nokunciphisa, ukunciphisa ukusetyenziswa kwamandla kunye neendleko zokugcina.

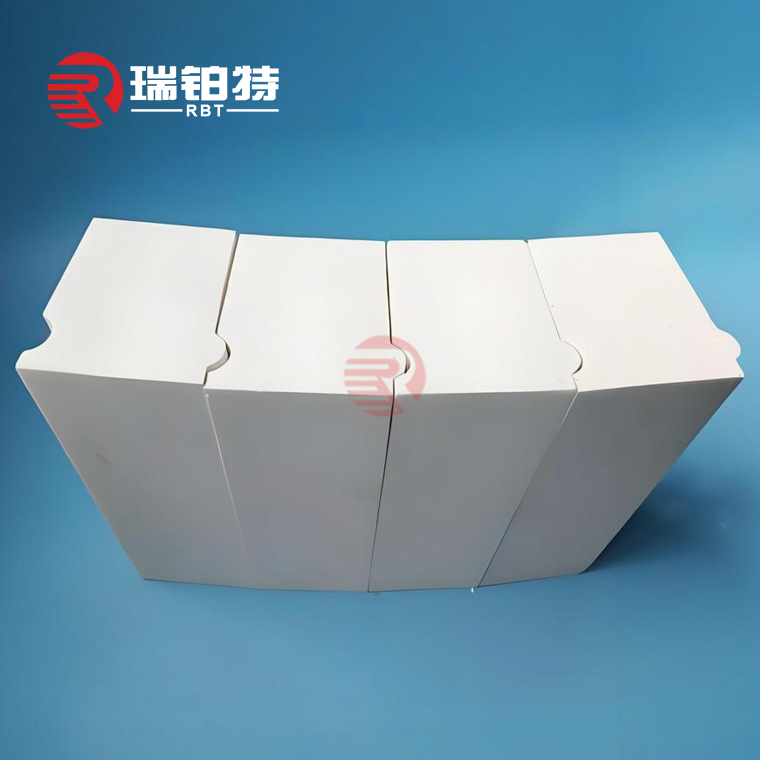

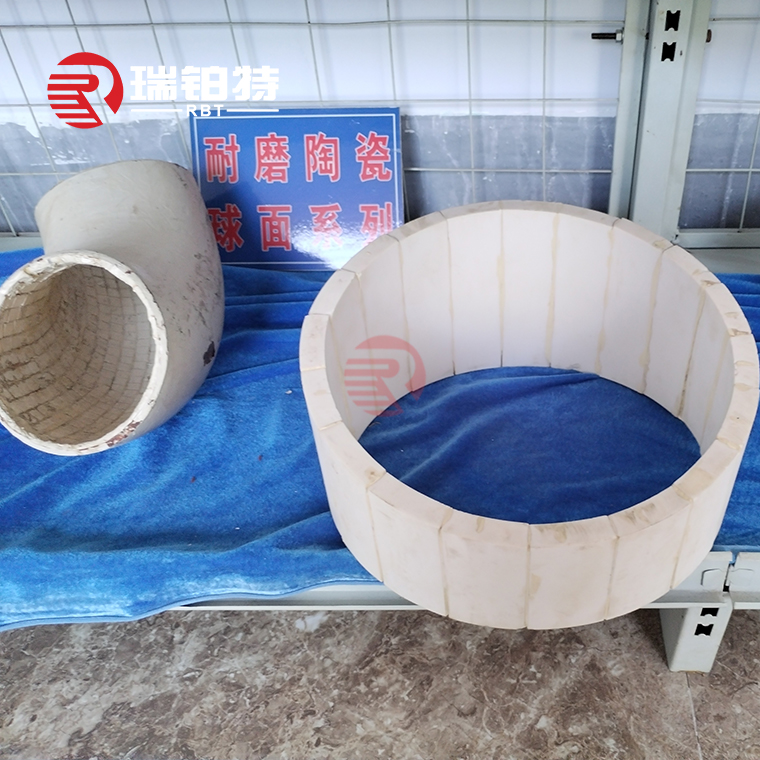

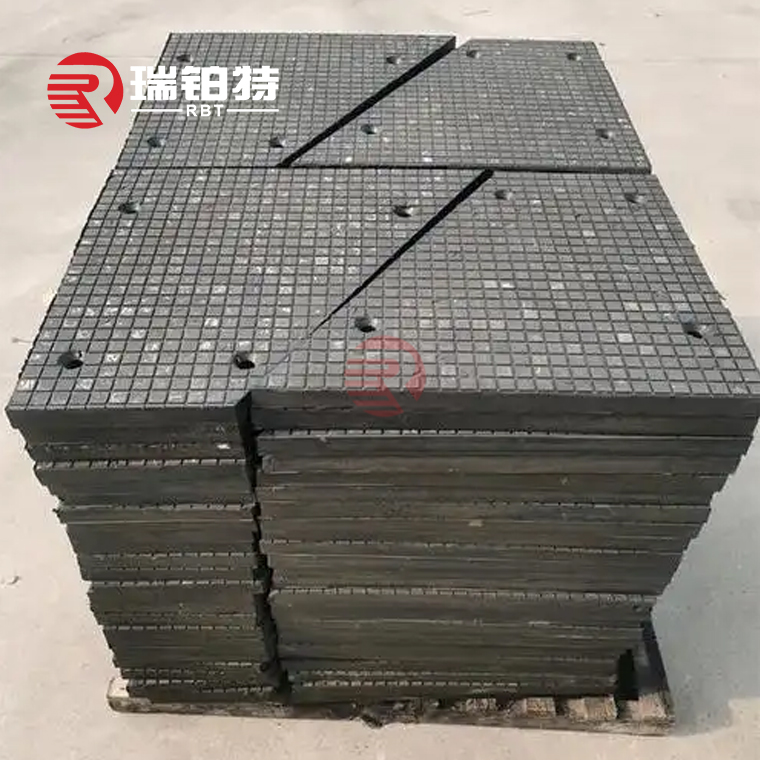

(3) Umbane we-ceramic ongagugiyo iipleyitiyimathiriyeli ene-alumina (AL2O3) njengomzimba oyintloko, eyongezwa kunye nezinye izithako, kwaye i-sintered kwiqondo lokushisa eliphezulu le-1700 ° C. Inokumelana nokugqwesa okugqwesileyo, ukuxhathisa umhlwa kunye nokuzinza kobushushu obuphezulu, kwaye isetyenziswa ngokubanzi ekugqithiseni amalahle, iinkqubo zokuhambisa izinto, iinkqubo zokwenza umgubo, ukukhutshwa kothuthu, iinkqubo zokususa uthuli kunye nezinye izixhobo zoomatshini ezinokunxiba okuphezulu kumandla obushushu, intsimbi, isinyithi, oomatshini, amalahle, imigodi, imichiza, isamente, iitheminali zezibuko kunye namanye amashishini.

Usetyenziso:

Ishishini lezemigodi:Ngethuba lokumbiwa kwemigodi, izixhobo zihlala zichatshazelwa ngama-abrasives kunye neempembelelo. Ukusetyenziswa kwe-ceramic-resistant lining ye-ceramic inokwandisa ngokufanelekileyo ubomi benkonzo yezixhobo kunye nokunciphisa iindleko zokugcina.

Ishishini leMetallological:Kwizixhobo ze-metallurgical, i-ceramic-resistant lining ye-ceramic inokumelana nokukhukuliseka kwesinyithi esityhidiweyo kunye ne-ore ukuqinisekisa ukusebenza okuzinzileyo kwezixhobo.

Ishishini lemichiza:Kwimveliso yeekhemikhali, izixhobo zihlala zibonakaliswe kumajelo atshabalalisayo. Ukusetyenziswa kwe-ceramic-resistant lining ye-ceramic kunokuphucula ukuqina kwezixhobo kunye nokunciphisa ukungaphumeleli okubangelwa ukubola. ...

Ishishini lamandla:Kwizixhobo zamandla, iileyile ze-ceramic ezingagungqiyo zinokunciphisa ngokufanelekileyo ukunxiba kothuli kunye namanye amasuntswana aqinileyo kwisixhobo, ukuqinisekisa ukusebenza okuzinzileyo kwexesha elide kwesixhobo.

4

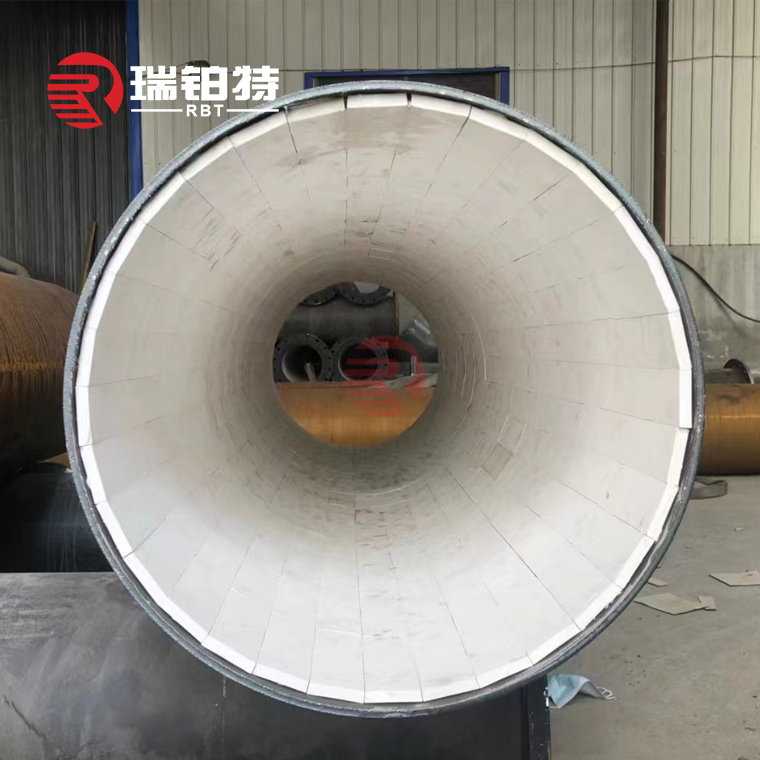

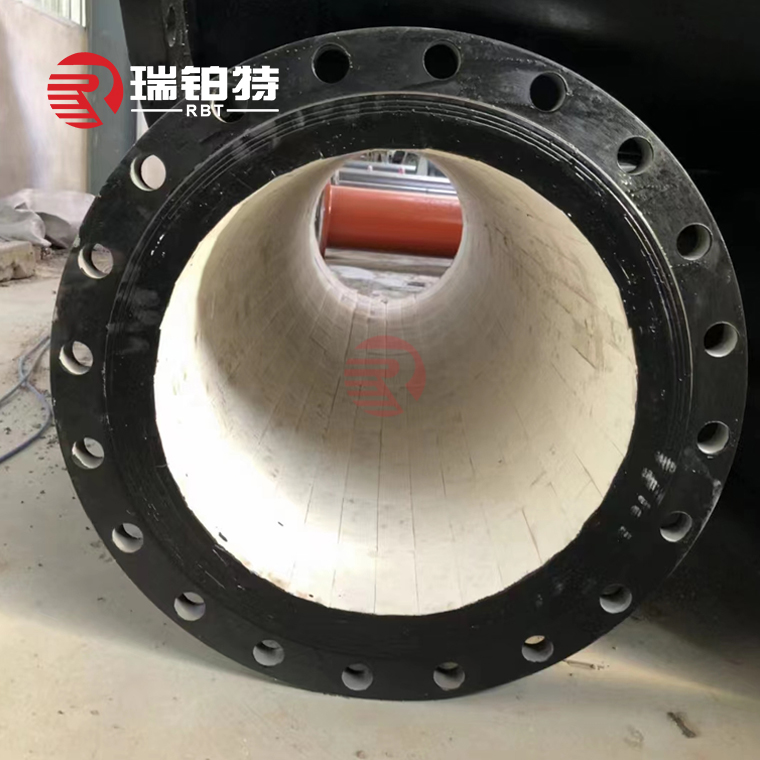

3. Umbhobho we-ceramic odityanisiweyo onganxibiyo, Igama elipheleleyo le-ceramic lined composite steel pipe, ngumbhobho owenziwe ngokusebenzisa inkqubo yokuvelisa i-high-tech-self-propagating high-temperature clutch synthesis method.

Iimbonakalo:

Ukumelana nokunxiba okuphezulu:Ukuqina kwe-Mohs ye-corundum ceramic lining inokufikelela kwi-9.0, enokumelana nokunxiba okuphezulu kakhulu kwaye ifanelekile ukuhambisa imidiya e-abrasive. ...

Ukuxhathisa umhlwa:Izixhobo zeCeramic zinokumelana kakuhle nemithombo yeendaba ezonakalisayo njengeeasidi, iialkali, kunye neetyuwa. ...

Uzinzo lobushushu obuphezulu:Uluhlu lwe-ceramic lunozinzo oluphezulu lwe-thermal kunye nokumelana ne-oxidation, kwaye ifanelekile kwiindawo eziphezulu zokushisa. ...

Ukukhanya kunye namandla aphezulu:Phakathi kwemibhobho yeenkcukacha ezifanayo kunye nobude beyunithi, umbhobho odibeneyo we-ceramic ongaguqukiyo ukhaphukhaphu ngobunzima, kodwa unokumelana okuqinileyo nokunxitywa kunye nokukhukuliseka kwamanzi.

Isicelo:

Imibhobho edityanisiweyo ye-ceramic engagugiyo isetyenziswa kakhulu kumandla, isinyithi, imigodi, amalahle, imichiza kunye namanye amashishini okuhambisa izinto zegranular ezirhabaxa kunye nemithombo yeendaba ezonakalisayo njengesanti, ilitye, umgubo wamalahle, uthuthu, ulwelo lwe-aluminiyam, njl.

Inkqubo yokuvelisa

Umbhobho we-ceramic odityanisiweyo we-centrifugal:Iveliswa kusetyenziswa "i-self-propagating high temperatures synthesis-high-speed centrifugal technology". Inkqubo ilula kwaye ixabiso liphantsi. Ifanelekile ukuthuthwa komgubo omde. ...

Umbhobho we-ceramic okwaziyo ukunxiba:Iphepha le-alumina ceramic lincanyathiselwe eludongeni lwangaphakathi lombhobho ngokuncamathelisa okuqinileyo kobushushu obuphezulu. Inkqubo yokuvelisa ilula kwaye ixabiso liphantsi. ...

Umbhobho oyintlanganisela ozazisayo:Ngokuxuba i-ceramic powder kunye ne-metal powder, i-sintered eludongeni lwangaphakathi lombhobho usebenzisa i-high-temperature synthesis kunye neendlela ze-centrifugal. Umbhobho we-ceramic odibeneyo odibeneyo: I-powder ye-ceramic ifakwe kumbhobho we-ceramic ngokokubumba kwaye idityaniswe nombhobho wentsimbi.

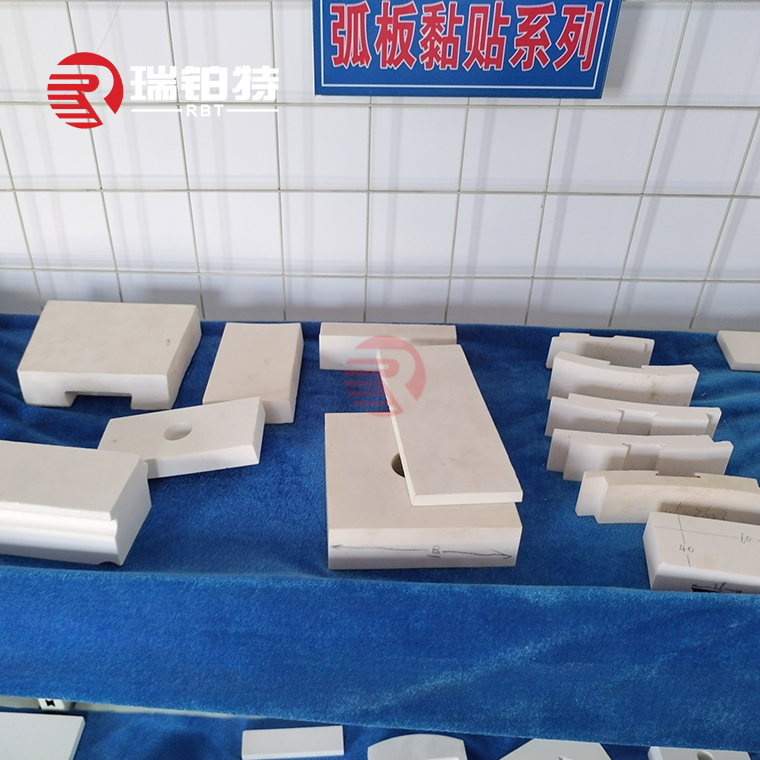

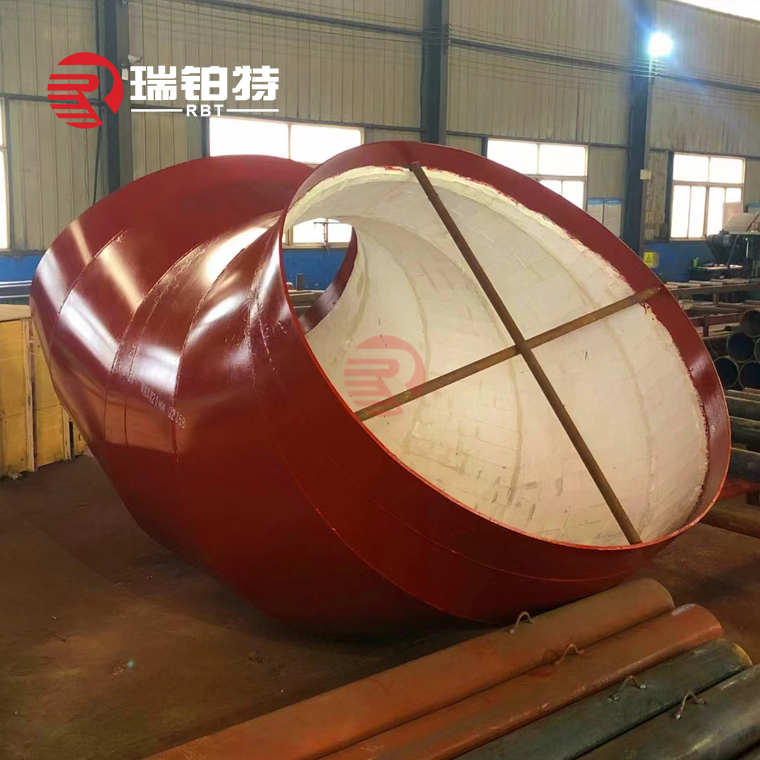

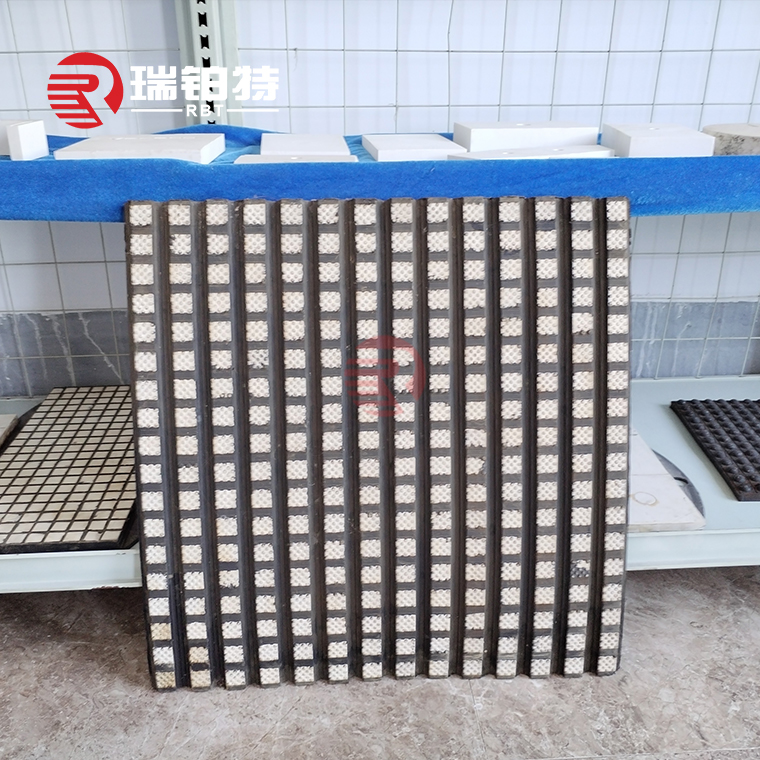

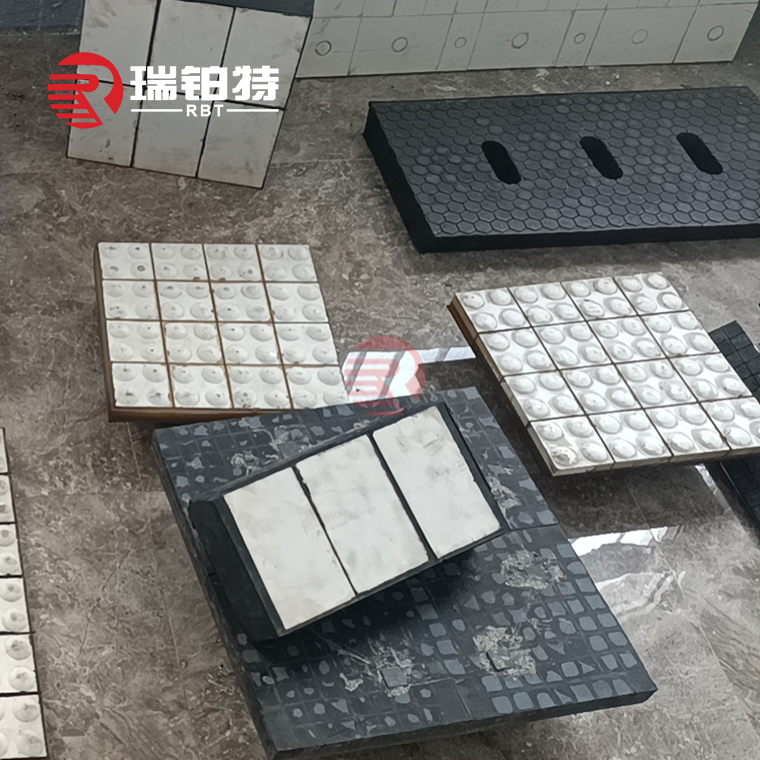

4. I-ceramic ezimbini-nye kunye nezintathu-kwinyeiipleyiti ezidibeneyozizinto ezidibeneyo ezidibanisa i-ceramic kunye ne-rubber materials, kunye nokumelana nokugqwesa okugqwesileyo, ukuxhathisa i-corrosion kunye nokumelana nempembelelo.

Inkqubo yokuvelisa

I-composite yerabha ye-ceramic ezimbini-kwinyeiipleyiti:Ngokusebenzisa itekhnoloji yerabha evulcanization, iiseramikhi ezinobunzima obuphezulu ze-alumina ziyavuzwa kwaye zifakwe kwirabha ekhethekileyo ukuze zenze umxube werabha yeceramic. Olu luhlu lusebenza kakuhle kwaye lunokuthintela ngokufanelekileyo impembelelo yentsimbi kunye nezinye izinto eziwa ukusuka kwindawo ephezulu. ...

Ithath-in-enye ekwazi ukumelana ne-ceramic compositeiipleyiti:Ngesiseko sesibini-enye, i-steel plate layer yongezwa. Ngokusebenzisa itekhnoloji yerabha yevulcanization, i-ceramic composite yerabha yenziwe ivulcanized kunye nepleyiti yentsimbi eneebholiti ezizinkiweyo ukuze zenze umdibaniso odityanisiweyo onesakhiwo sesithathu-kwisinye. Esi sakhiwo siqinisekisa ubudlelwane obusondeleyo phakathi kwee-ceramics, i-rubber kunye neeplate zetsimbi, ngelixa zibonelela ngemiphumo eyongezelelweyo yokulungisa.

Iimpawu zokusebenza

Ukumelana nokunxiba:Umaleko we-ceramic unobunzima obuphezulu kakhulu, obunokuthi buxhathise ngokufanelekileyo ukunxiba kunye nokwandisa ubomi benkonzo yesixhobo.

...Ukuchasa impembelelo:Uluhlu lwerabha lune-elasticity elungileyo kunye nokuchasana kwempembelelo, inokuthatha impembelelo kunye nokunyakaza okwenziwa ngexesha lokusebenza kwezixhobo, kunye nokukhusela i-ceramic layer kumonakalo. ...

Ukuxhathisa umhlwa:Zombini ii-ceramics kunye nerabha zinokuxhathisa okulungileyo kokutya kwaye zinokusebenza ngokuzinzileyo ixesha elide kwiindawo ezirhabaxa. ...

Khaphukhaphu:I-plate ye-lining kwi-three-in-one structure ingaphezulu kwe-60% ilula kune-plate yensimbi engagugiyo, kwaye ikulungele kakhulu ukuyifaka kunye nokutshintsha.

Isicelo:

Ukwembiwa kwemigodi:Isetyenziselwa izixhobo ezinganxibiyo njengeebhola zebhola, ii-mill zamalahle, izinyusi zamabhakethi,i-scraper conveyors, njl.njl ukuphucula ukusebenza kakuhle kunye nokuzinza kwezixhobo. ...

IMetallurgy:Kwizixhobo ezahlukeneyo kwishishini le-metallurgical, iipleyiti ze-ceramic ezidityanisiweyo ezinokunxitywa zinokuxhathisa ngokufanelekileyo ukunxiba kobushushu obuphezulu, uxinzelelo oluphezulu kunye nezixhobo ezitshisayo. ...

Umbane:Kwinkqubo yokuthutha amalahle, izixhobo zokususa uthuli kunye nezinye iindawo zoshishino lwamandla, ukunciphisa ukunxiba izixhobo kunye nokunciphisa iindleko zokugcina. ...

Ishishini lemichiza:Kwii-reactors, iitanki zokugcina kunye nezinye izixhobo kwishishini lemichiza, zixhathise ukukhukuliseka kweendaba ezahlukeneyo zeekhemikhali kunye nokwandisa ubomi benkonzo yezixhobo.

Isalathiso seMveliso

| Into | Al2O3 >92% | >95% | >99% | >99.5% | >99.7% |

| Umbala | Mhlophe | Mhlophe | Mhlophe | Umbala weCream | Umbala weCream |

| Uxinaniso lwethiyori(g/cm3) | 3.45 | 3.50 | 3.75 | 3.90 | 3.92 |

| Ukugoba Amandla(Mpa) | 340 | 300 | 330 | 390 | 390 |

| Amandla acinezelayo(Mpa) | 3600 | 3400 | 2800 | 3900 | 3900 |

| Elastic Modulus(Gpa) | 350 | 350 | 370 | 390 | 390 |

| Ukumelana neMpembelelo(Mpam1/2) | 4.2 | 4 | 4.4 | 5.2 | 5.5 |

| I-Weibull Coefficient(m) | 11 | 10 | 10 | 12 | 12 |

| Vickers Hardness(HV 0.5) | 1700 | 1800 | 1800 | 2000 | 2000 |

| I-Coefficient yoKwandiswa kweThermal | 5.0-8.3 | 5.0-8.3 | 5.1-8.3 | 5.5-8.4 | 5.5-8.5 |

| I-Thermal Conductivity(W/mk) | 18 | 24 | 25 | 28 | 30 |

| Thermal Shock Uzinzo | 220 | 250 | 250 | 280 | 280 |

| Obona bushushu bokusebenza℃ | 1500 | 1600 | 1600 | 1700 | 1700 |

| 20℃ Ukuchasa uMqulu | >10^14 | >10^14 | >10^14 | >10^15 | >10^15 |

| Amandla eDielectric (kv/mm) | 20 | 20 | 20 | 30 | 30 |

| Dielectric Constant | 10 | 10 | 10 | 10 | 10 |

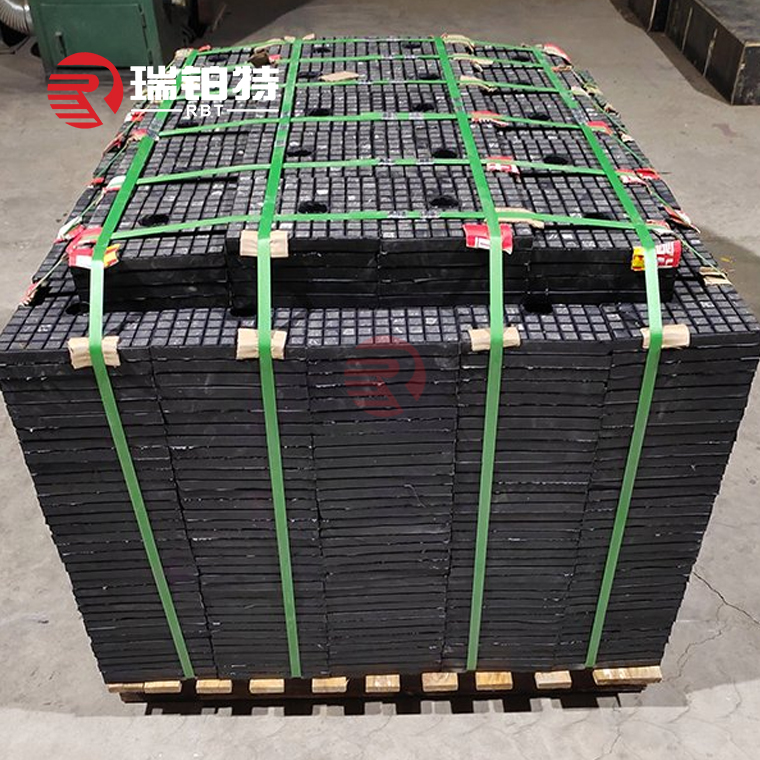

Umboniso womzi-mveliso

Iprofayile yekhampani

Shandong Robert New Material Co., Ltd.ibekwe kwisiXeko saseZibo, kwiPhondo laseShandong, eTshayina, esisiseko sokuvelisa izinto ezichasayo. Siyishishini lanamhlanje elidibanisa uphando kunye nophuhliso, imveliso, intengiso, uyilo lwe-kiln kunye nolwakhiwo, itekhnoloji, kunye nezinto zokuthumela ngaphandle. Sinezixhobo ezipheleleyo, itekhnoloji ephucukileyo, amandla obuchule obuqinileyo, umgangatho wemveliso ogqwesileyo, kunye nodumo oluhle. Umzi-mveliso wethu ugubungela iihektare ezingaphezulu kwama-200 kwaye imveliso yonyaka yezinto ezimilise okwemilo imalunga neetoni ezingama-30000 kunye nemathiriyeli engamiliselwanga yerefractory ziitoni eziyi-12000.

Iimveliso zethu eziphambili zemathiriyeli ye-refractory ziquka:izinto zokunqanda i-alkaline; i-aluminiyam i-silicon refractory izinto; izinto zokuchasa ezingamiliselwanga; izinto zokunqanda ukushisa kwe-thermal; izixhobo ezikhethekileyo zokuchasa; izinto ezisebenzayo zokunqanda iinkqubo zokuphosa eziqhubekayo.

Imibuzo ebuzwa qho

Dinga uncedo? Qiniseka ukuba undwendwela iiforam zethu zenkxaso ukuze ufumane iimpendulo kwimibuzo yakho!

Singumvelisi wokwenyani, umzi-mveliso wethu ukhethekileyo ekuveliseni izinto eziphikisayo iminyaka engaphezu kwama-30. Sithembisa ukubonelela ngexabiso elingcono, elona xabiso lilungileyo lokuthengisa kwangaphambili kunye nenkonzo emva kokuthengisa.

Kwinkqubo nganye yokuvelisa, i-RBT inenkqubo epheleleyo ye-QC yokwakheka kweekhemikhali kunye neempawu ezibonakalayo. Kwaye siya kuvavanya iimpahla, kwaye isatifikethi somgangatho siya kuthunyelwa kunye neempahla. Ukuba uneemfuno ezizodwa, siya kuzama konke okusemandleni ethu ukuze sizilungiselele.

Ngokuxhomekeke kubungakanani, ixesha lethu lokuhambisa lihlukile. Kodwa sithembisa ukuthumela ngokukhawuleza kunye nomgangatho oqinisekisiweyo.

Ngokuqinisekileyo, sinikezela ngeesampuli zamahhala.

Ewe, kunjalo, wamkelekile ukuba undwendwele inkampani ye-RBT kunye neemveliso zethu.

Akukho mda, sinokubonelela ngengcebiso kunye nesisombululo esilungileyo ngokwemeko yakho.

Senze izinto eziphikisayo iminyaka engaphezu kwe-30, sinenkxaso eqinile yobugcisa kunye namava atyebileyo, sinokunceda abathengi bayile ii-kilns ezahlukeneyo kunye nokubonelela ngenkonzo yokumisa enye.