Izitena zeCorundum/izitena zeCorundum Mullite

Ulwazi lweMveliso

Isitena seCorundumIimveliso ezichasene ne-corundum njengesigaba esiphambili sekristale, kunye nomxholo we-alumina odlula i-90%.

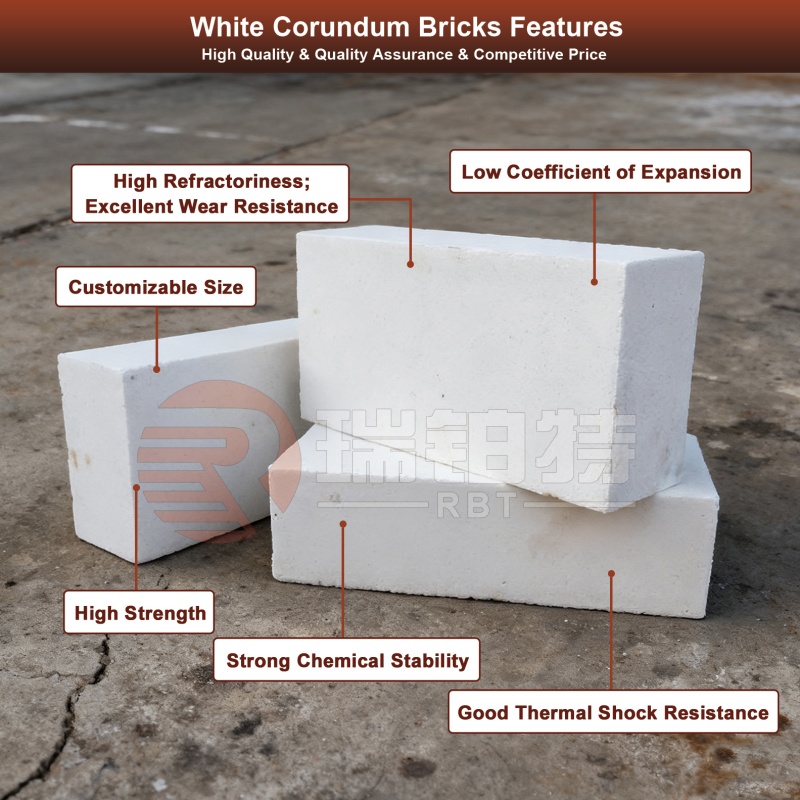

Udidi:Izitena zeCorundum zahlulwe ngokubanzi zibe zizitena zecorundum ezisinteziweyo kunye nezitena zecorundum ezisinteziweyo. Eyokuqala yenziwe nge-sintered alumina, ngelixa eyesibini yenziwe nge-fused corundum. Izitena zecorundum ezingatshayelwanga zinokwenziwa kusetyenziswa i-phosphoric acid okanye ezinye izibopheleli.

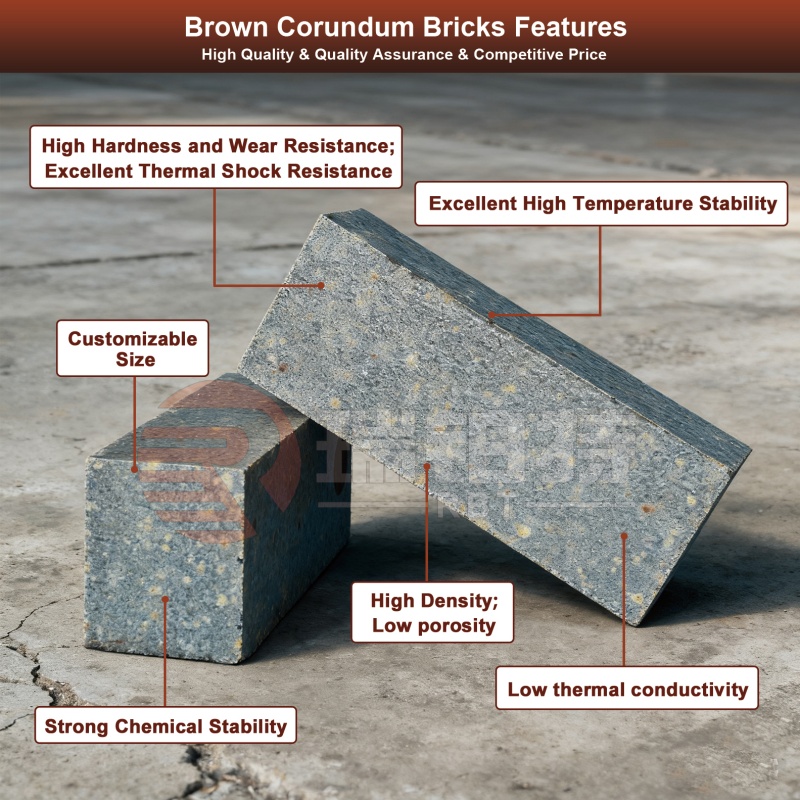

Iimpawu Zokusebenza:

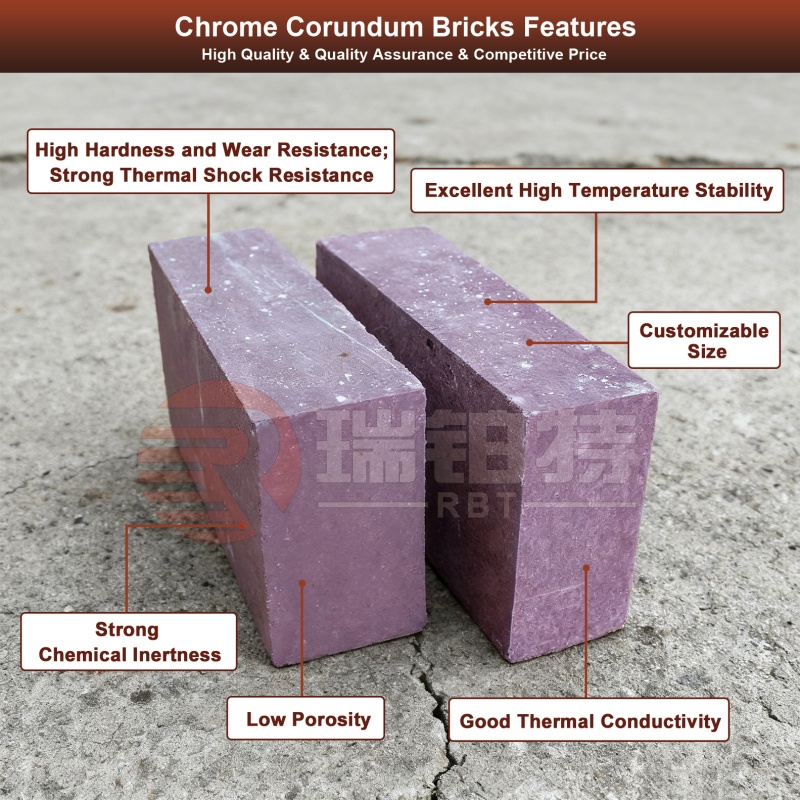

Iimpawu Ezintle Zokurhawuzelela:Ubushushu obuthambileyo obungaphantsi komthwalo wezitena ze-corundum budlula i-1700°C, kwaye ezinye izitena ze-chrome corundum zinokufikelela kubushushu obudlula i-1790°C. Zihlala zizinzile kwiindawo ezinobushushu obuphezulu kwaye azichaphazeleki kukuguquka okanye kukonakala.

Amandla aphezulu:Amandla okucinezela ezitena ze-corundum ezicocekileyo kakhulu kubushushu begumbi ngokubanzi yi-70MPa-100MPa, ngelixa ezo zezitena ze-chrome corundum ezisebenza kakuhle zidlula i-150MPa kwaye zinokufikelela kwi-340MPa.

Uzinzo Olulungileyo Lweekhemikhali:Izitena zeCorundum ziyakwazi ukumelana kakhulu ne-asidi okanye i-alkaline slags, iintsimbi, kunye neglasi enyibilikisiweyo, kwaye azichaphazeleki ziikhemikhali.

Ukumelana okunamandla nokukhukuliseka kwenkunkuma:Umzekelo, umxholo weCr₂O₃ kwizitena ze-chrome corundum uthintela ngempumelelo i-slag enyibilikisiweyo ukuba ingangeni emzimbeni wezitena ngemingxunya ye-capillary, nto leyo ebangela ukuba ukukhukuliseka kwe-slag kube ngcono kwizitena ze-corundum eziqhelekileyo.

Izithako eziphambili kunye nezixhobo eziluhlaza:

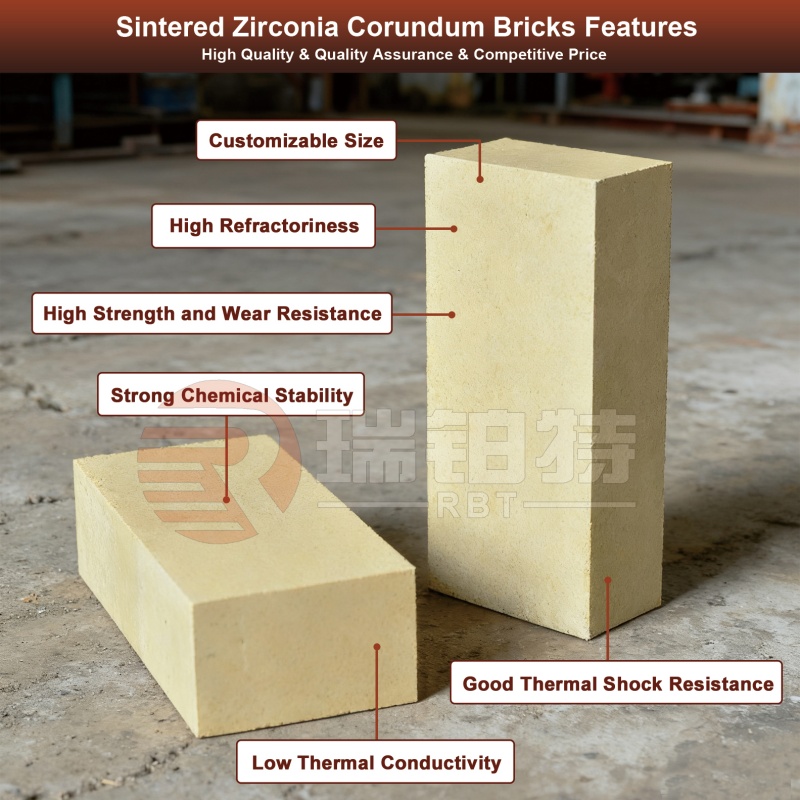

Eyona nto iphambili kwizitena ze-corundum yi-alumina (Al₂O₃), edla ngokudlula i-90%, ezinye ziqulathe ukuya kuthi ga kwi-99%. Izinto ezisetyenzisiweyo ziquka i-sintered alumina kunye ne-fused corundum. Ezinye izinto zeminerali zingongezwa ukwenza izinto ezidityanisiweyo, ezifana ne-Cr₂O₃ kwizitena ze-chrome corundum kunye ne-ZrO₂ kwizitena ze-zirconium corundum.

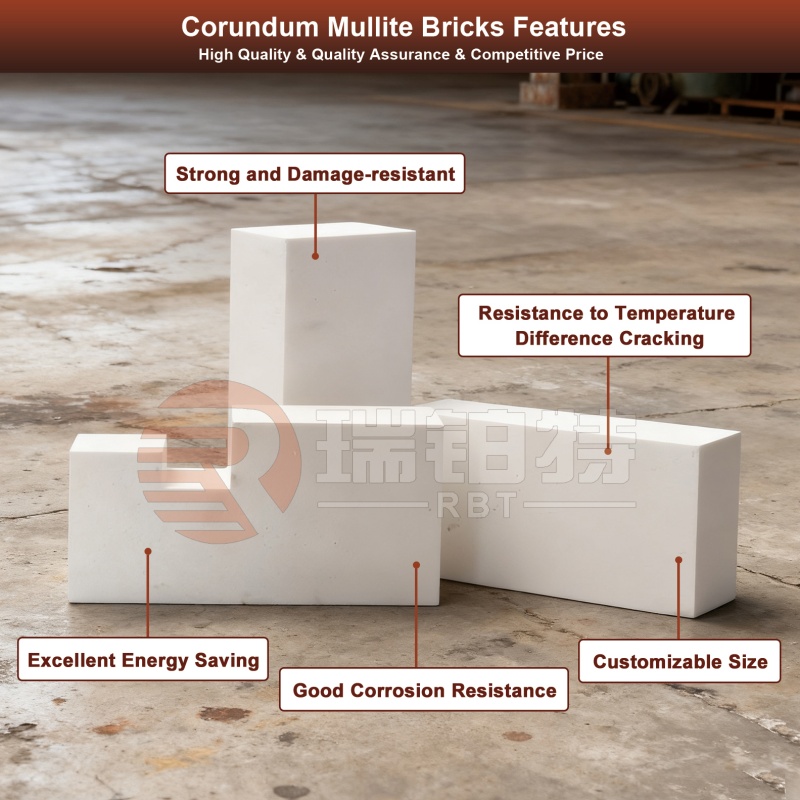

Izitena zeCorundum-mulliteziitena ezidityanisiweyo ezichaseneyo ezakhiwe ngamanqanaba amabini azinzileyo obushushu obuphezulu: i-corundum (Al₂O₃) kunye ne-mullite (3Al₂O₃・2SiO₂). Zidibanisa amandla aphezulu e-corundum kunye nokumelana okuhle kakhulu nobushushu be-mullite, nto leyo ezenza zibe zizinto ezishushu kakhulu ezilinganisela ukusebenza kunye nokusebenza kakuhle kweendleko.

Izinto eziPhambili kunye neempawu zoLwakhiwo

Ulwakhiwo lweSigaba esiPhambili seCrystalline:I-Corundum kunye ne-mullite zii-crystal phases ezimbini eziphambili, apho umxholo we-alumina uqhele ukusuka kwi-70% ukuya kwi-90%, kwaye intsalela ikakhulu yi-silicon dioxide (SiO₂). Isiphumo sokusebenzisana kwezi zigaba zimbini silinganisa ukusebenza.

Ulwakhiwo oluncinci:Ii-Mullite phases zisasazwa phakathi kweenkozo ze-corundum ngendlela yeekristale ezimile okwenaliti okanye ezikwi-columnar, zenza isakhiwo "se-corundum skeleton + mullite connection". Oku akupheleli nje ekukhuliseni amandla ezitena kodwa kukwathintela uxinzelelo lobushushu ngokusebenzisa izikhewu ze-micro-crystal.

Iingenelo eziphambili zokusebenza

Ukumelana okugqwesileyo koxinzelelo lobushushu:Le yeyona nzuzo yayo iphambili. I-Mullite inomlinganiselo ophantsi wokwanda kobushushu, kwaye isakhiwo sayo sekristale esimile okwenaliti sitsala uxinzelelo olubangelwa kukuguquguquka kobushushu, kunciphisa kakhulu ukuqhekeka okubangelwa kukupholisa ngokukhawuleza kunye nokufudumeza kumaqondo obushushu aphezulu. Ukusebenza kwayo kudlula ukusebenza kwezitena ze-corundum ezicocekileyo.

Amandla alinganayo kunye nokumelana nokugqwala:Ubukho besigaba se-corundum buqinisekisa amandla aphezulu kwigumbi kunye namaqondo obushushu aphezulu, ngelixa bukwabonelela ngokumelana okuhle ne-asidi ye-slag, iglasi enyibilikisiweyo, kunye nezinye izinto. Nangona ukumelana kwayo ne-alkali kungaphantsi kancinci kunokwezitena ze-chrome corundum, inika uluhlu olubanzi lwezicelo.

Ukuqhuba kobushushu okuphakathi:Xa ithelekiswa nezitena ze-corundum ezinoxinano oluphezulu, inika ukuhanjiswa kobushushu obuphantsi ngelixa igcina inqanaba elithile lokufakelwa kobushushu, inciphisa ukulahleka kobushushu kwizixhobo zobushushu obuphezulu kwaye iyenza ifaneleke kwizicelo ezifuna ukufakwa kobushushu obuphezulu.

Isalathiso seMveliso

| Izitena zeCorundum | ||||

| ISALATHISO | I-GYZ-99A | I-GYZ-99B | I-GYZ-98 | I-GYZ-95 |

| I-Al2O3 (%)≥ | 99 | 99 | 98 | 95 |

| I-SiO2 (%)≤ | 0.15 | 0.2 | 0.5 | --- |

| I-Fe2O3 (%)≤ | 0.10 | 0.15 | 0.2 | 0.3 |

| Ukuqhekeka Okubonakalayo (%)≤ | 19 | 19 | 19 | 20 |

| Ubuninzi bobuninzi (g/cm3) ≥ | 3.20 | 3.15 | 3.15 | 3.1 |

| Amandla okutyumza abandayo (MPa) ≥ | 80 | 80 | 80 | 100 |

| Utshintsho olusisigxina lwe-Linear (1600°×3h) /% | -0.2~+0.2 | -0.2~+0.2 | -0.2~+0.2 | -0.3~+0.3 |

| Ukungaguquguquki koMthwalo (0.2MPa, 0.6%)/℃ ≤ | 1700 | 1700 | 1700 | 1700 |

| Izitena zeCorundum-mullite | ||||

| ISALATHISO | I-GMZ-88 | I-GMZ-85 | GMZ-80 | I-GYZ-75 |

| I-Al2O3 (%)≥ | 88 | 85 | 80 | 75 |

| I-Fe2O3 (%)≤ | 0.8 | 1.0 | 1.0 | 1.2 |

| Ukuqhekeka Okubonakalayo (%)≤ | 15(17) | 16(18) | 18(20) | 18(20) |

| Ubuninzi bobuninzi (g/cm3) ≥ | 3.00 | 2.85 | 2.75 | 2.60 |

| Amandla okutyumza okubandayo (MPa) | 100-120 | 80-100 | 80-100 | 60-80 |

| Utshintsho olusisigxina lwe-Linear (1600°×3h) /% | -0.1~+0.1 | -0.1~+0.1 | -0.2~+0.2 | -0.2~+0.2 |

| Ukungaguquguquki koMthwalo (0.2MPa, 0.6%)/℃ ≤ | 1700 | 1680 | 1650 | 1650 |

Isicelo

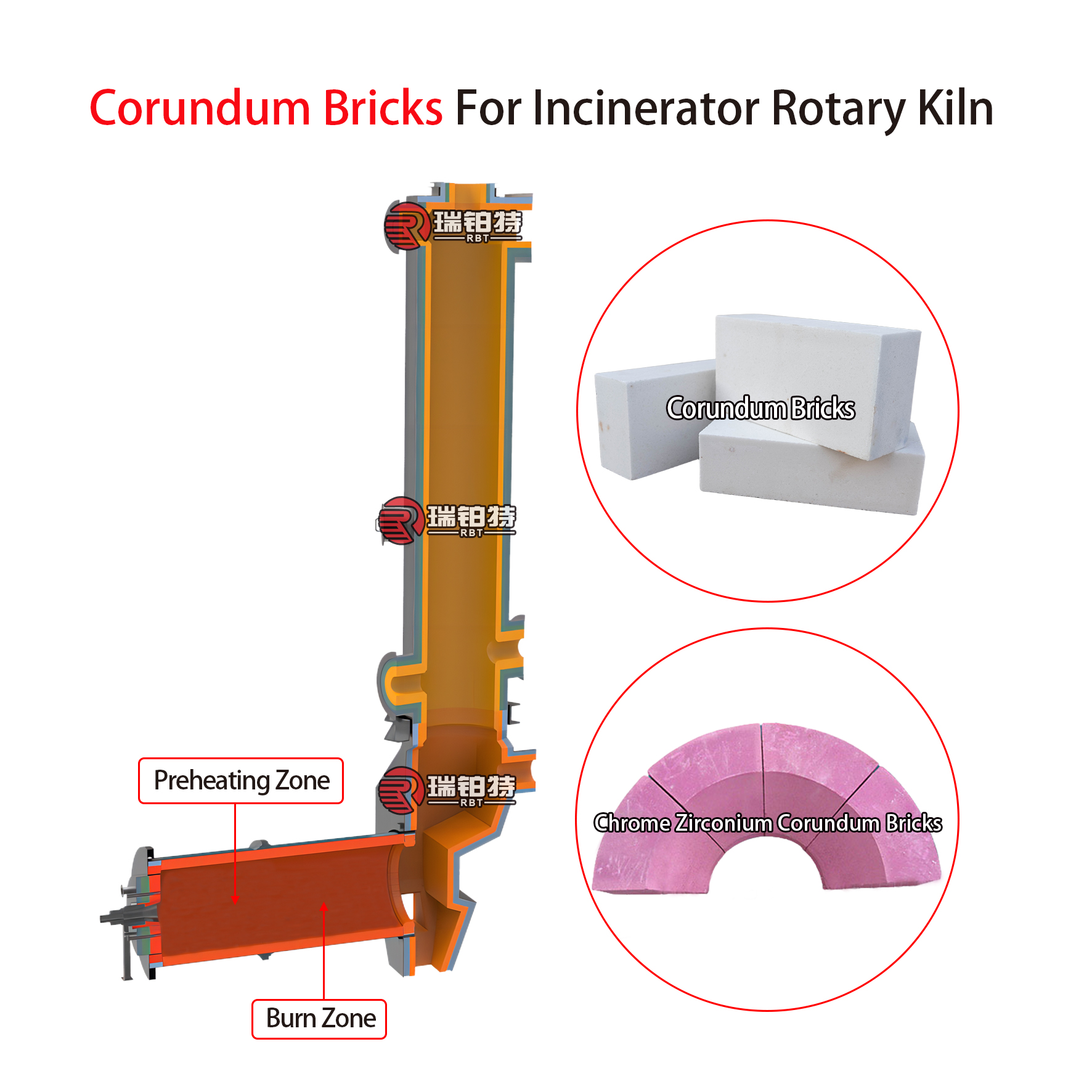

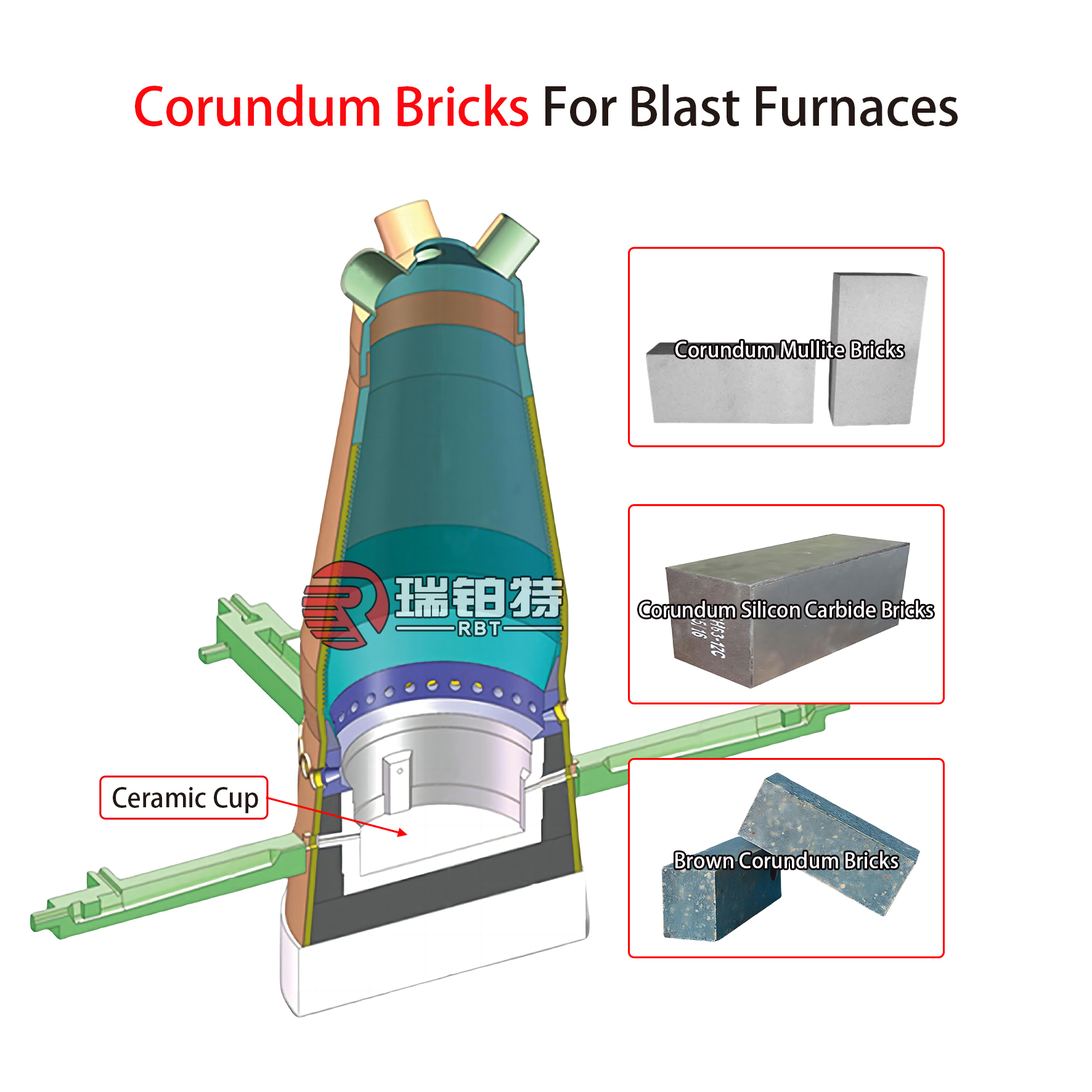

Ukusetyenziswa kwezitena zeCorundum:

Ishishini leNsimbi:Isetyenziselwa ukubiyela izixhobo zokunyibilikisa ezishushu kakhulu ezifana nee-converters, ii-electrical furniture, kunye nee-refined furniture, kunye nezixhobo ezifana nee-slides, ii-stoppers, kunye neenkqubo zokuthulula ukuze kuqhutyekwe kuphoswa.

Ukunyibilikisa isinyithi okungeyo-ferrous:Zifakwe kwii-oven zokunyibilikisa nezokucoca iintsimbi ezingeyo-ferrous ezifana ne-aluminium, i-copper, kunye ne-nickel.

Ishishini leglasi:Isetyenziswa kakhulu kwizitena zokukhangela kwiindawo zokuhlaziya kunye neendawo zokutshaja zee-ovens zeglasi ezinyibilikisayo.

Ishishini leSamente:Ifakwe kwindawo yokutshisa enobushushu obuphezulu yee-oven zesamente ezijikelezayo.

Ushishino lweeKhemikhali:Ifakwe kwiireactors ezishushu kakhulu kunye nee-ovens eziqhekekayo.

Ishishini laMandla:Ifakwe izixhobo zonyango lwegesi yokukhupha umoya eshushu kakhulu kunye nezixhobo zokufaka igesi.

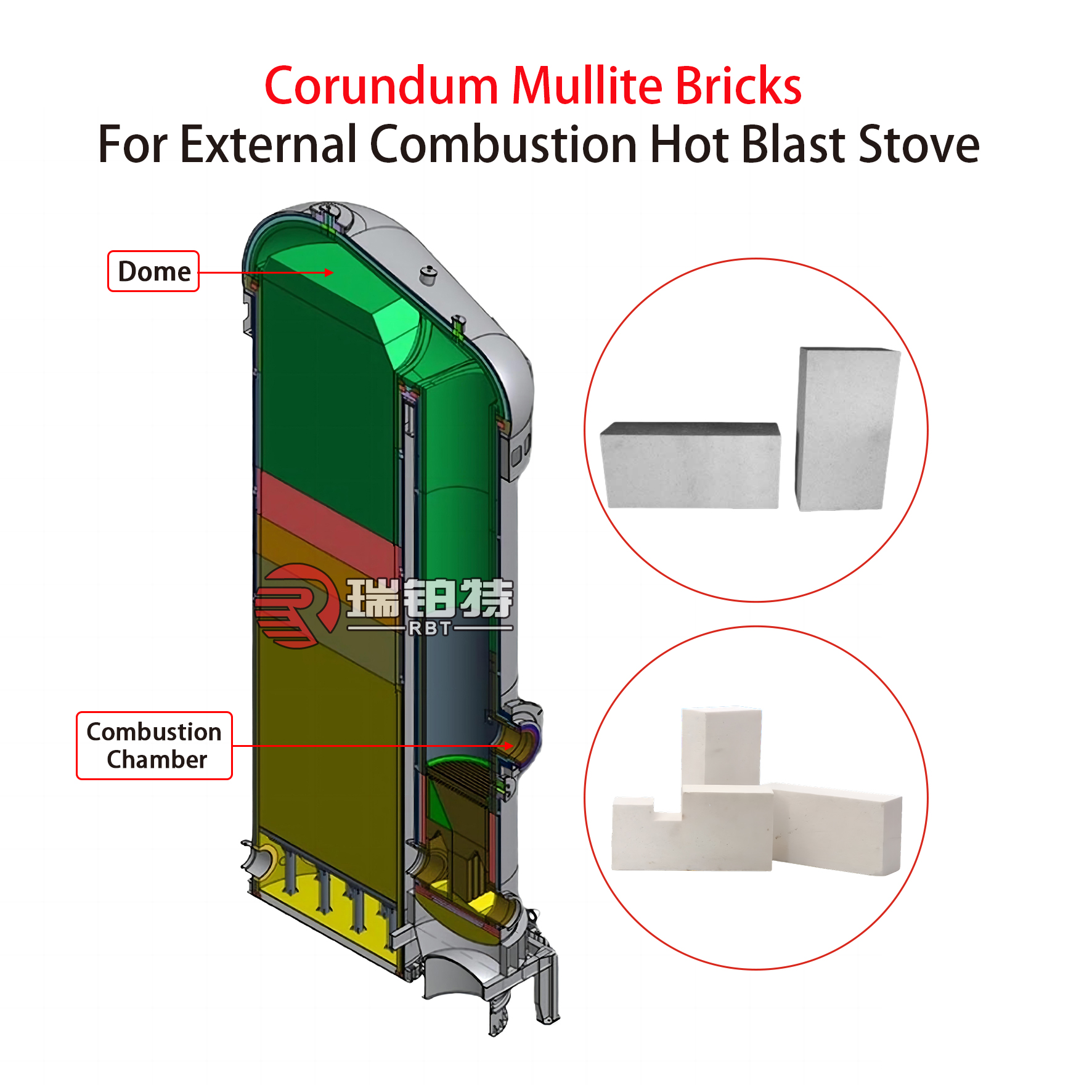

Izicelo eziphambili zeCorundum Mullite Bricks

Ishishini leSamente:Zifakwe kwindawo yokutshintsha kwaye zilungelelaniswe nee-kiln ezijikelezayo zesamente. Ziyakwazi ukumelana nokuguquguquka okukhulu kobushushu ngaphakathi kwi-kiln ejikelezayo ngelixa zixhathisa iigesi ezirhabaxa eziveliswa kukubola kwezinto eziluhlaza zesamente.

Ishishini leglasi:Zisetyenziswa kwizitena zeglasi ezijonga i-regenerator furnace kunye neendonga ze-oven, ziyamelana nokuguquguquka rhoqo kobushushu kwaye azigugi lula yiglasi enyibilikisiweyo.

Ushishino lweMetallurgy kunye neeKhemikhali:Ifanelekile ukusetyenziswa kwiindawo ezinobushushu obuphakathi nobuphantsi zee-oven zesinyithi ezingenayo i-ferrous, ii-linings ze-oven zokosa ezishushu kakhulu, kunye nezixhobo zokosa ezithwala i-catalyst kwishishini leekhemikhali, amandla okulinganisela kunye neemfuno zokumelana nobushushu.

Iprofayile yekhampani

I-Shandong Robert New Material Co., Ltd.ikwiSixeko saseZibo, kwiPhondo laseShandong, eTshayina, elisisiseko semveliso yezinto ezinganyangekiyo. Silishishini lanamhlanje elidibanisa uphando nophuhliso, imveliso, ukuthengisa, uyilo lwe-oven kunye nolwakhiwo, iteknoloji, kunye nezixhobo ezinganyangekiyo ezithunyelwa kwamanye amazwe. Sinezixhobo ezipheleleyo, iteknoloji ephucukileyo, amandla obuchwephesha aqinileyo, umgangatho wemveliso ogqwesileyo, kunye nodumo oluhle. Umzi-mveliso wethu ugubungela iihektare ezingaphezu kwama-200 kwaye imveliso yonyaka yezixhobo ezinganyangekiyo ezimile imalunga neetoni ezingama-30000 kwaye izinto ezinganyangekiyo ezimile ziitoni ezili-12000.

Iimveliso zethu eziphambili zezinto ezichasayo ziquka: izinto ezichasayo ze-alkaline; izinto ezichasayo ze-aluminium silicon; izinto ezichasayo ezingabunjwanga; izinto ezichasayo ze-thermal insulation; izixhobo ezikhethekileyo ezichasayo; izixhobo ezichasayo ezisebenzayo kwiinkqubo zokuphosa eziqhubekayo.

Imibuzo ebuzwa qho

Ngaba ufuna uncedo? Qiniseka ukuba undwendwela iiforam zethu zenkxaso ukuze ufumane iimpendulo kwimibuzo yakho!

Singumvelisi wokwenyani, umzi-mveliso wethu ugxile ekuveliseni izinto ezichasene nendalo kangangeminyaka engaphezu kwama-30. Sithembisa ukubonelela ngexabiso elifanelekileyo, eyona nkonzo ingcono ngaphambi kokuthengisa nasemva kokuthengisa.

Kwinkqubo nganye yemveliso, i-RBT inenkqubo epheleleyo ye-QC yokwakheka kweekhemikhali kunye neempawu zomzimba. Kwaye siza kuvavanya iimpahla, kwaye isatifikethi somgangatho siya kuthunyelwa kunye neempahla. Ukuba uneemfuno ezizodwa, siza kuzama konke okusemandleni ethu ukuzilungiselela.

Ngokuxhomekeke kubungakanani, ixesha lethu lokuhambisa lahlukile. Kodwa sithembisa ukuthumela ngokukhawuleza kangangoko kunokwenzeka ngomgangatho oqinisekisiweyo.

Kakade ke, sinikezela ngeesampuli zasimahla.

Ewe, ewe, wamkelekile ukutyelela inkampani ye-RBT kunye neemveliso zethu.

Akukho mda, singakunika ingcebiso nesisombululo esifanelekileyo ngokwemeko yakho.

Besisenza izinto ezirhabaxa kangangeminyaka engaphezu kwama-30, sinenkxaso yobugcisa enamandla kunye namava amaninzi, singanceda abathengi ukuba bayile ii-kiln ezahlukeneyo kwaye banikezele ngenkonzo enye.