Kwintsimi enkulu yemveliso yemizi-mveliso eshushu kakhulu, iishelufu ze-oven, njengezinto eziphambili ezithwala izinto zokucubungula ubushushu obuphezulu, ukusebenza kwazo kuchaphazela ngokuthe ngqo ukusebenza kakuhle kwemveliso, umgangatho wemveliso, kunye neendleko zemveliso. Nangona kunjalo, xa iishelufu ze-oven zemveli zijongene neendawo ezinzima ezifana nobushushu obuqhubekayo, ukutshayiswa rhoqo kobushushu, ukuguguleka kwezinto, kunye nokubola kweekhemikhali, zihlala zihlangabezana neengxaki ezifana nobomi obufutshane benkonzo, ukuguqulwa nokuqhekeka, kunye neendleko eziphezulu zokugcinwa, ezithintela kakhulu ukusebenza okuzinzileyo kwemveliso. Ukuvela kweeshelufu ze-oven ze-silicon carbide, kunye neenzuzo zazo zokusebenza ezibalaseleyo, kuzise inkqubela phambili eguqukayo kwimveliso yemizi-mveliso eshushu kakhulu.

Iingenelo Ezibalaseleyo ZeeShelufu ZeSilicon Carbide Kiln

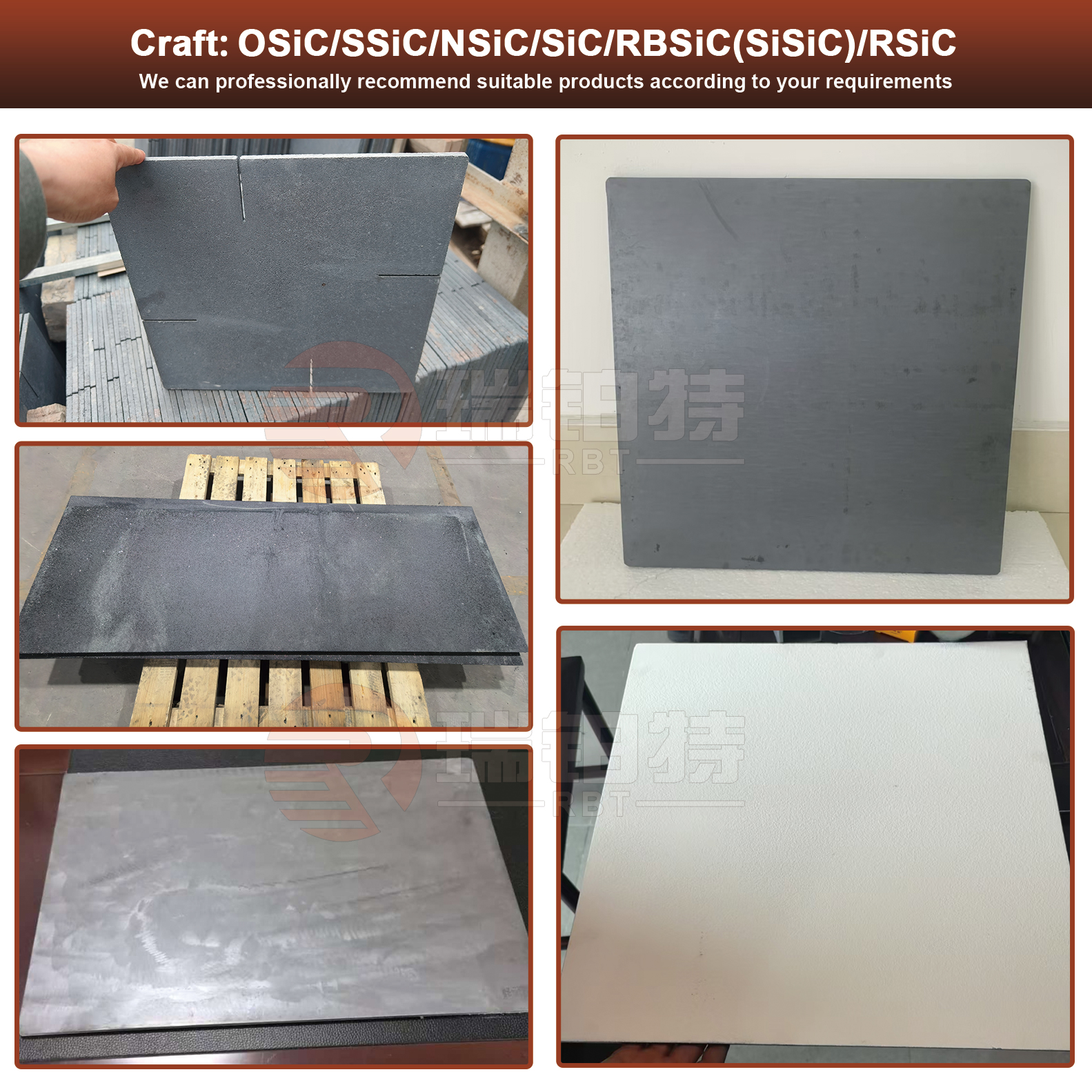

Iishelufu ze-silicon carbide kiln zinokuba zezona zithandwayo kumashishini ashushu kakhulu ngenxa yeenzuzo ezininzi ezinikwe ziimpawu zazo ezikhethekileyo:

Ukumelana Okuphezulu Nobushushu Obuphezulu: Izinto ze-silicon carbide ngokwazo zinendawo yokunyibilika ephezulu kakhulu, nto leyo evumela iishelufu ze-silicon carbide kiln ukuba zikwazi ukumelana lula neendawo ezinobushushu obuphezulu obungaphezulu kwe-1600°C. Zisebenza ngokuzinzileyo ngexesha lokusebenza kobushushu obuphezulu ixesha elide kwaye aziyi kuthamba, zitshintshe, okanye zibe neminye imiba ngenxa yobushushu obuphezulu, nto leyo eqinisekisa ukufana kunye nokuzinza kwenkqubo yokufudumeza izinto kwi-oven.

Ukumelana nokunxiba okugqwesileyo:I-silicon carbide inobunzima obuphezulu kakhulu, kwaye ukumelana kwayo nokuguguleka kuphezulu kakhulu kuneeshelufu ze-oven zemveli ezenziwe ngodongwe, i-aluminium ephezulu, kunye nezinye izinto. Ngexesha lokulayisha kunye nokuhambisa izinto, iishelufu ze-silicon carbide oven zinokumelana ngempumelelo nokungqubana kunye nempembelelo yezinto, zinciphise ukuguguleka komphezulu, ngaloo ndlela zigcina ubushushu obuhle kwaye ziqinisekise ukufudumeza okufanayo kwezinto.

Ukumelana noTshabalalo oluKhethekileyo:Kwimveliso yemizi-mveliso eshushu kakhulu, iishelufu ze-oven zihlala ziphantsi kweenkqubo zokufudumeza nokupholisa ngokukhawuleza, nto leyo ebeka iimfuno eziphezulu kakhulu ekumelaneni kwazo nobushushu. Iishelufu ze-oven ze-silicon carbide zine-coefficient ephantsi kakhulu yokwandiswa okuthe ngqo kunye nokuqhuba kakuhle kobushushu, okunokumelana ngempumelelo noxinzelelo lobushushu olubangelwa kukutshintsha kweqondo lobushushu ngequbuliso kwaye kunciphise kakhulu ukwenzeka kokuqhekeka, ukuqhekeka, kunye nezinye izinto.

Ubomi beNkonzo ende kakhulu:Ngenxa yeempawu ezintle ezingentla, ubomi benkonzo yeeshelufu ze-silicon carbide kiln bude kakhulu kunezo zeeshelufu ze-kiln zemveli. Phantsi kweemeko ezifanayo zokusebenza, ubomi benkonzo yazo bunokuba bude ngokuphindwe kathathu ukuya kahlanu okanye bube ngaphezulu kunobo beeshelufu ze-kiln zemveli, nto leyo enciphisa kakhulu ukuphindaphindeka kokutshintshwa kweeshelufu ze-kiln kunye nelahleko yemveliso kunye neendleko zomsebenzi ezibangelwa kukuvalwa kokutshintshwa.

Uzinzo Olulungileyo Lweekhemikhali:Izinto ze-silicon carbide zinokumelana kakhulu nezinto ezibangela ukubola ezifana nee-asidi kunye ne-alkalis. Kwezinye ii-oven ezishushu kakhulu ezineegesi okanye izinto ezibangela ukubola, zinokugcina iipropati zeekhemikhali ezizinzileyo kwaye akulula ukuba zonakaliswe ziimpendulo zeekhemikhali, nto leyo eqinisekisa ukusebenza okuzinzileyo kwe-oven.

Ukusebenza kakuhle kweeshelufu ze-silicon carbide kiln kuye kwenza ukuba zisetyenziswe kakhulu kwiindawo ezininzi zoshishino ezishushu kakhulu.Kwishishini le-ceramic, nokuba kukutshiswa kweeseramikhi zemihla ngemihla, iiseramikhi zokwakha, okanye iiseramikhi ezikhethekileyo, iishelufu ze-silicon carbide kiln zinokumelana nemeko enzima yee-kiln ezinobushushu obuphezulu, ziqinisekise ukufudunyezwa okufanayo kwee-blanks zeseramikhi ngexesha lenkqubo yokutshiswa, kwaye ziphucule amazinga okufaneleka kwemveliso.Kwishishini lesinyithi, zingasetyenziswa kwiikhonkco zokucubungula ezishushu kakhulu ezifana nokunyibilikisa nokunyibilikisa izinto zesinyithi, zixhathisa ukubola kwesinyithi esinyibilikisiweyo kunye ne-slag.Kwishishini le-elektroniki, ukulungiselela iimveliso ezichanekileyo kakhulu ezifana neeseramikhi ze-elektroniki kunye nezixhobo ze-semiconductor ngobushushu obuphezulu, uzinzo kunye nokucoceka kweeshelufu ze-silicon carbide kiln zinokuhlangabezana neemfuno ezingqongqo zemveliso. Ukongeza, iishelufu ze-silicon carbide kiln nazo zidlala indima ebalulekileyo kwimveliso eshushu kakhulu kumashishini afana neglasi kunye nezinto ezichaseneyo.

Ngokukhetha iishelufu zethu ze-silicon carbide kiln, uya kufumana iimveliso ezikumgangatho ophezulu kunye neziqinisekiso zenkonzo epheleleyo. Sisebenzisa iinkqubo zemveliso eziphambili kunye nezinto eziluhlaza ezikumgangatho ophezulu, kwaye silawula ngokungqongqo yonke ikhonkco ukusuka ekuhlanganiseni, ekwakheni, ekutshiseni ukuya ekuvavanyweni ukuqinisekisa ukuba ishelufu nganye ye-kiln iyahlangabezana neemfuno zomgangatho ophezulu. Sineqela lobuchwephesha elinokubonelela ngezisombululo zemveliso ezenzelwe wena kunye nenkxaso yobugcisa ngokweemeko ezithile zokusebenza kunye neemfuno zabathengi abahlukeneyo. Kwangaxeshanye, simisele inkqubo yenkonzo ephilileyo emva kokuthengisa ukuphendula ngokukhawuleza imibuzo kunye neemfuno zabathengi kunye nokusombulula iingxaki ezidibene nabathengi ngexesha lokusetyenziswa.

Ukuba ujonge iishelufu ze-oven ezisebenza kakuhle nezihlala ixesha elide, ungakhetha iishelufu zethu ze-silicon carbide oven. Ziya kubonelela ngeziqinisekiso ezithembekileyo zemveliso yakho yoshishino eshushu kakhulu, zikuncede uphucule ukusebenza kakuhle kwemveliso kwaye unciphise iindleko zemveliso. Wamkelekile ukuba unxibelelane nathi nangaliphi na ixesha ukuze ufumane ulwazi oluthe kratya ngemveliso, ubuze ngeekowuteshini, okanye wenze utshintshiselwano lobuchwephesha. Silangazelela ukusebenzisana nawe ukudala ikamva elingcono.

Ixesha leposi: Julayi-16-2025