Iimfuno jikelele zezixhobo ezichasayo kwiifurnaces zombane zezi:

(1) I-refractoriness kufuneka ibe phezulu.Ukushisa kwe-arc kudlula i-4000 ° C, kwaye ukushisa kwe-steelmaking yi-1500 ~ 1750 ° C, ngamanye amaxesha ukuphakama kwe-2000 ° C, ngoko ke izinto eziphikisayo zifuneka ukuba zibe ne-refractoriness ephezulu.

(2) Ubushushu obuthambileyo phantsi komthwalo kufuneka bube phezulu.Isithando sombane sisebenza phantsi kweemeko zomthwalo ophezulu weqondo lokushisa, kwaye umzimba wesithando somlilo kufuneka umelane nokukhukuliseka kwensimbi etyhidiweyo, ngoko ke into ephikisayo iyadingeka ukuba ibe nobushushu obuphezulu bokuthambisa.

(3) Amandla oxinzelelo kufuneka abe phezulu.Umbane wesithando sombane uchaphazeleka yimpembelelo yentlawulo ngexesha lokutshaja, uxinzelelo lwe-static lwentsimbi etyhidiweyo ngexesha lokunyibilika, ukukhukuliseka kokuhamba kwentsimbi ngexesha lokucofa, kunye nokungcangcazela komatshini ngexesha lokusebenza.Ngoko ke, i-refractory imathiriyeli iyafuneka ukuba ibe namandla aphezulu oxinzelelo.

(4) I-thermal conductivity kufuneka ibe yincinci.Ukuze kuncitshiswe ilahleko yobushushu besithando sombane kunye nokunciphisa ukusetyenziswa kwamandla, i-refractory material iyadingeka ukuba ibe ne-thermal conductivity engafanelekanga, oko kukuthi, i-coefficient conductivity ye-thermal kufuneka ibe yincinci.

(5) Ukuzinza kwe-thermal kufuneka kube kuhle.Kwimizuzu embalwa ukusuka ekucofeni ukuya ekutshabhiseni kwi-steelmaking yesithando sombane, ubushushu behla ngokukhawuleza ukusuka malunga ne-1600 ° C ukuya ngaphantsi kwe-900 ° C, ngoko ke izinto eziphikisayo ziyafuneka ukuba zibe nokuzinza okulungileyo kwe-thermal.

(6) Ukuxhathisa okuqinileyo kwe-corrosion.Ngethuba lenkqubo yokwenza i-steelmaking, i-slag, igesi yesithando somlilo kunye nentsimbi etyhidiweyo zonke zineempembelelo eziqinileyo zokukhukuliseka kweekhemikhali kwizinto eziphikisayo, ngoko ke izinto eziphikisayo ziyafuneka ukuba zibe nokumelana nokubola okulungileyo.

Ukukhethwa kwezinto eziphikisayo kwiindonga zecala

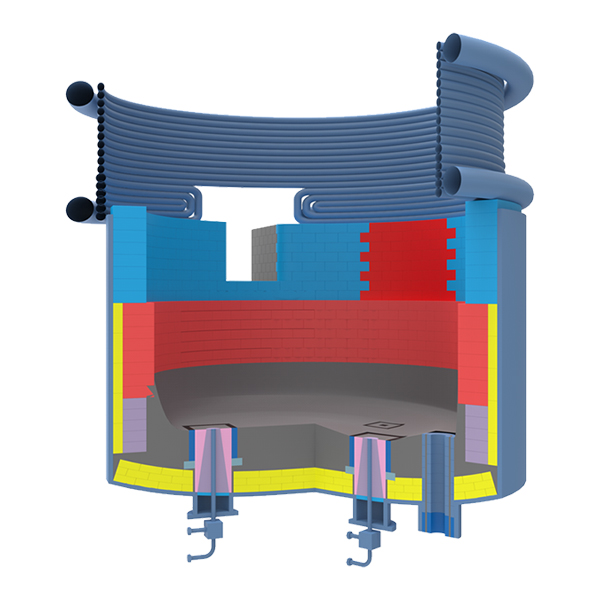

Izitena ze-MgO-C zihlala zisetyenziselwa ukwakha iindonga zecala leziko zombane ngaphandle kweendonga zokupholisa amanzi.Iindawo ezishushu kunye nemigca ye-slag ineemeko ezinzima kakhulu zenkonzo.Abagcini nje ngokugqwesa kakhulu kwaye bachithwa yintsimbi etyhidiweyo kunye ne-slag, kunye nefuthe elibi lomatshini xa i-scrap yongezwa, kodwa ixhomekeke kwimitha ye-thermal evela kwi-arc.Ngoko ke, ezi nxalenye zakhiwe ngezitena ze-MgO-C kunye nokusebenza okugqwesileyo.

Kwiindonga zecala leziko zombane ngeendonga ezipholileyo ngamanzi, ngenxa yokusetyenziswa kwetheknoloji yokupholisa amanzi, umthwalo wokushisa uyanda kwaye iimeko zokusetyenziswa zingqongqo.Ngoko ke, izitena ze-MgO-C ezinokuchasana kakuhle kwe-slag, ukuzinza kwe-thermal shock kunye ne-high conductivity ye-thermal kufuneka kukhethwe.Umxholo wabo wekhabhoni yi-10% ~ 20%.

Izinto ezichasayo kwiindonga zecala le-ultra-high power furnaces zombane

Iindonga ezisecaleni ze-ultra-high power furnaces (i-UHP furnaces) zakhiwe kakhulu ngezitena ze-MgO-C, kunye neendawo ezishushu kunye neendawo ze-slag zakhiwe ngezitena ze-MgO-C kunye nokusebenza okugqwesileyo (ezifana ne-carbon matrix epheleleyo ye-MgO-C izitena).Ukuphucula kakhulu ubomi bayo benkonzo.

Nangona umthwalo wodonga lwesithando somlilo uncitshisiwe ngenxa yokuphuculwa kweendlela zokusebenza zesithando sombane, kusenzima kwizinto eziphikisayo zokwandisa ubomi benkonzo yeendawo ezishushu xa zisebenza phantsi kweemeko zokunyibilikisa kwesithando se-UHP.Ngoko ke, iteknoloji yokupholisa amanzi iye yaphuhliswa kwaye yasetyenziswa.Kwiindawo zombane zombane usebenzisa i-EBT tapping, indawo yokupholisa amanzi ifikelela kwi-70%, ngaloo ndlela inciphisa kakhulu ukusetyenziswa kwezinto eziphikisayo.Itekhnoloji yanamhlanje yokupholisa amanzi ifuna izitena zeMgO-C ezine-conductivity entle ye-thermal.I-Asphalt, izitena ze-resin-bonded magnesia kunye nezitena ze-MgO-C (i-carbon content 5% -25%) zisetyenziselwa ukwakha iindonga ezisecaleni zesithando sombane.Ngaphantsi kweemeko ezinzima ze-oxidation, i-antioxidants yongezwa.

Kwiindawo ezitshisa kakhulu ezonakaliswe kakhulu yi-redox reactions, izitena ze-MgO-C ezine-crystalline fused magnesite enkulu njengento eluhlaza, umxholo wekhabhoni omkhulu kune-20%, kunye ne-carbon matrix epheleleyo isetyenziselwa ukwakhiwa.

Uphuhliso lwamva nje lwezitena ze-MgO-C kwiziko lombane ze-UHP kukusebenzisa ukudubula kobushushu obuphezulu kunye nokufakwa kwe-asphalt ukuvelisa izitena ezibizwa ngokuba yi-asphalt-impregnated MgO-C.Njengoko kunokubonwa kwiThebhile yesi-2, xa kuthelekiswa nezitena ezingabonakaliyo, umxholo wekhabhoni oshiyekileyo wezitena ze-MgO-C ezitshisiweyo emva kokufakelwa kwe-asphalt kunye ne-recarbonization inyuka malunga ne-1%, i-porosity iyancipha nge-1%, kunye nokushisa okuphezulu kwamandla kunye noxinzelelo. Ukuxhathisa are Amandla aphuculwe kakhulu, ngoko unokuqina okuphezulu.

I-Magnesium refractory izinto zombane ezindongeni zesithando sombane

Iziko lomlilo lombane lihlulwe libe yi-alkaline kunye ne-acidic.Owokuqala usebenzisa izinto ezinqambileyo ze-alkaline (ezifana ne-magnesia kunye ne-MgO-CaO izinto eziphikisayo) njenge-furnace lining, ngelixa lo mva usebenzisa izitena ze-silica, isanti ye-quartz, udaka olumhlophe, njl.

Qaphela: Kwizixhobo zombane zomlilo, iziko zombane ze-alkaline zisebenzisa izinto ezinqandayo ze-alkaline, kunye nezixhobo zombane ezine-acidic zisebenzisa izinto ezinqabileyo ezinqabileyo.

Ixesha lokuposa: Oct-12-2023