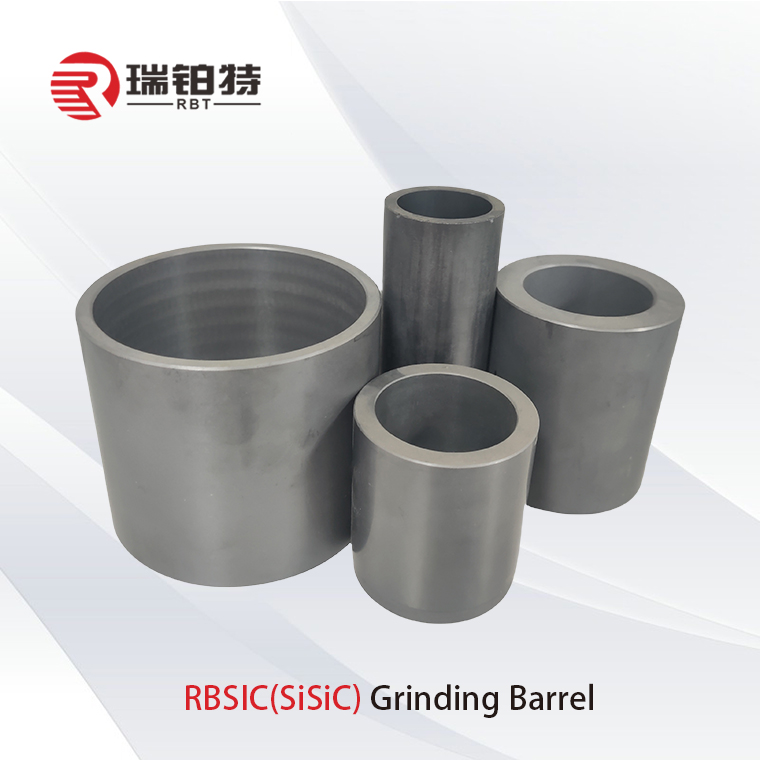

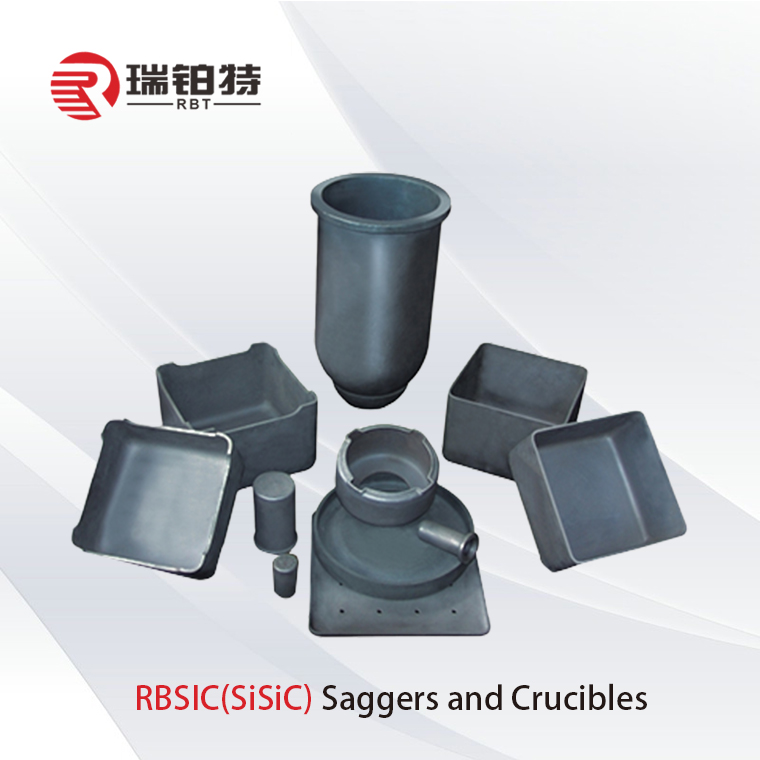

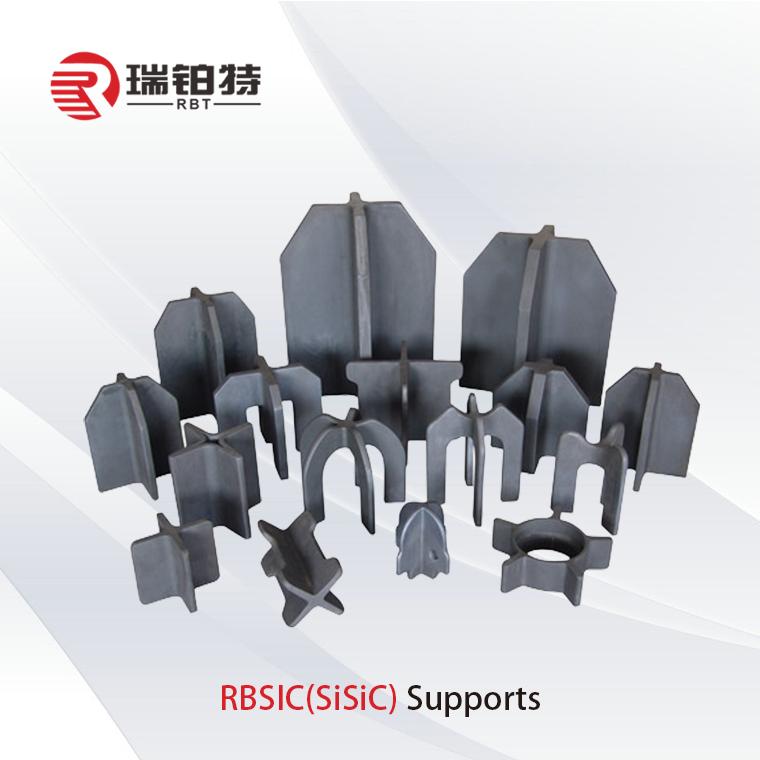

Iimveliso ze-RBSiC (SiSiC).

Ulwazi lweMveliso

| ImvelisoIgama | Iimveliso ze-RBSIC(SiSiC)(Iimveliso ze-Sintering Silicon Carbide) |

| Inkcazo | I-Siliconized SiC yimpendulo ye-silicon exutywe ngokulinganayo kwaye ifakwe ngamasuntswana amahle e-SiC, i-carbon powder kunye nezongezo ngokulinganayo ukuvelisa i-SiC kunye nokudibanisa ne-SiC, i-silicon engaphezulu igcwalisa izithuba zokufumana izinto ezixineneyo ze-ceramic. |

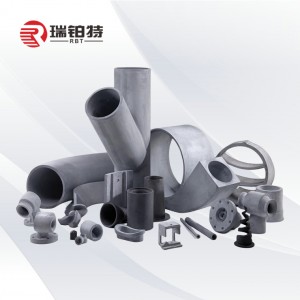

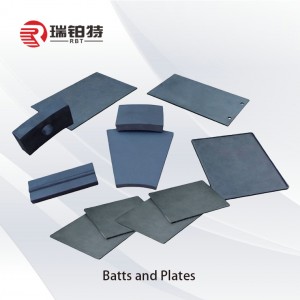

| Uphawu | Izinto zesiliconized silicon carbide zinoluhlu olusisiseko sobungangamsha kunye neempawu ezinje ngokuqina okuphezulu, ukuqina okugqithisileyo, ukumelana nokunxiba, ukunyamezela ubushushu obuphezulu, ukuxhathisa kwe-corrosion, ukumelana ne-oxidation yokumelana nomothuko we-thermal, ukuhanjiswa okuphezulu kwe-thermal, i-coefficient ephantsi yokwandiswa kwe-thermal, ukuxhathisa kwe-creep. ubushushu obuphezulu njalo njalo. Iimveliso ezininzi zinokwenziwa ngayo njengemiqadi, iirola, imibhobho yomoya epholileyo, iityhubhu zokukhusela isibini esishushu, iityhubhu zokulinganisa ubushushu, iindawo zokutywina, kunye neenxalenye ezikhethekileyo ezimile. |

Isalathiso seMveliso

| Into | Iyunithi | Idatha |

| Ubushushu obuphezulu beSicelo | ℃ | ≤1380 |

| Ukuxinana | g/cm3 | -3.02 |

| Vula i-Porosity | % | ≤0.1 |

| Ukugoba Amandla | Mpa | 250(20℃);280(1200℃) |

| Imodyuli ye-Elastictiy | Gpa | 330(20℃);300(1200℃) |

| I-Thermal Conductivity | W/mk | 45(1200℃) |

| I-Coefficient yoKwandiswa kweThermal | K-1*10-6 | 4.5 |

| Ukuqina kukaMoh | | 9.15 |

| I-Acid Alkaline-Ubungqina | | Egqwesileyo |

Iinkcukacha Imifanekiso

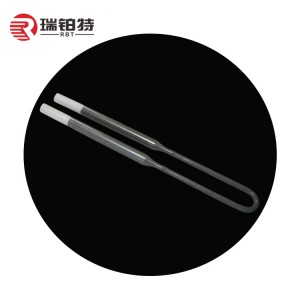

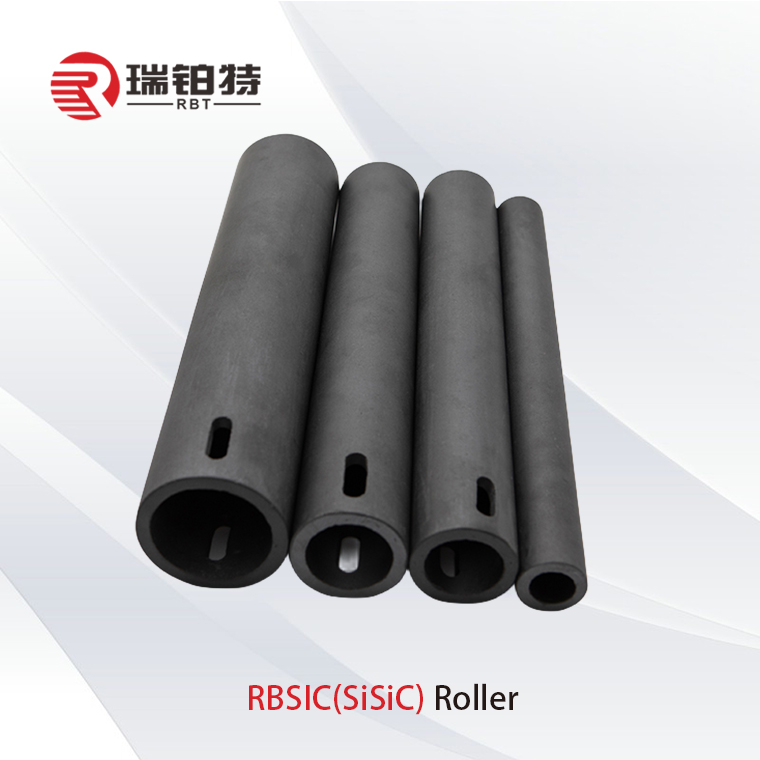

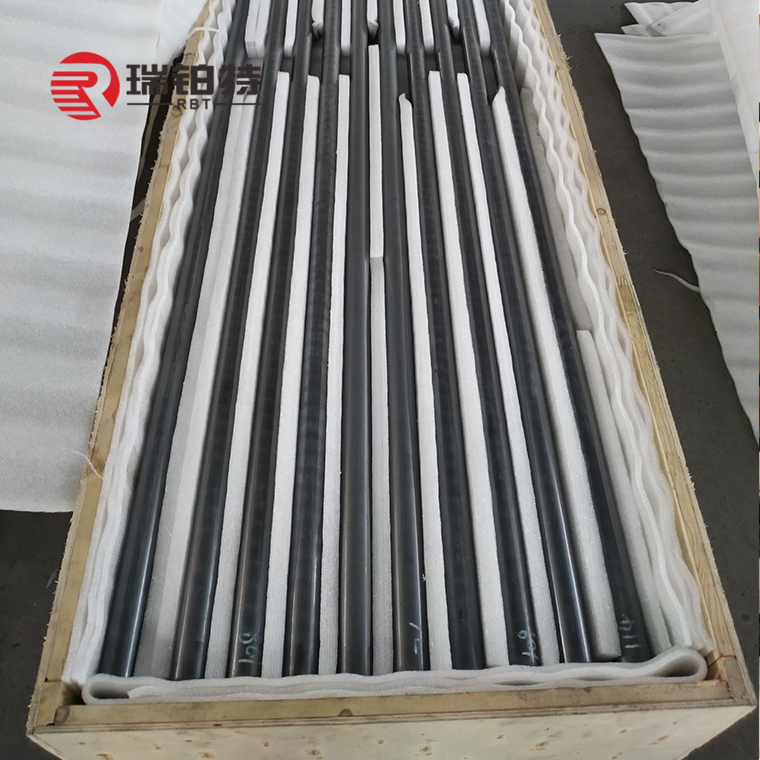

Uphawu:Ukumelana nokugqwesa kweekhemikhali okugqwesileyo kwe-silicon carbide roll rod kuyenza isebenze ixesha elide kwindawo eyomeleleyo ye-corrosion ye-lithium electric kiln, kwaye inobomi obude.

| Ukuthwala uMmandla weRBSic (SiSiC) Rollers | |||

| UbungakananiyeIcandelo(mm) | UdongaUkutyeba(mm) | IgxininiseIyalayisha(kg.m/L) | NgokufanayoKusasazweIyalayisha(kg.m/L) |

| 30 | 5 | 43 | 86 |

| 35 | 5 | 63 | 126 |

| 35 | 6 | 70 | 140 |

| 38 | 5 | 77 | 154 |

| 40 | 6 | 97 | 197 |

| 45 | 6 | 130 | 260 |

| 50 | 6 | 167 | 334 |

| 60 | 7 | 283 | 566 |

| 70 | 7 | 405 | 810 |

Isicelo:I-kiln yokuqubha, i-tonnel kiln, i-roller kiln, kunye nezinye izakhiwo ze-industrial kiln kunye neemveliso ezithwala iilori.

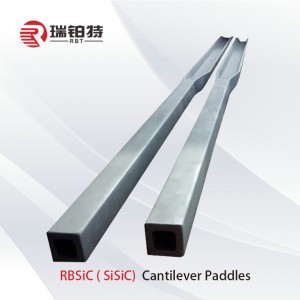

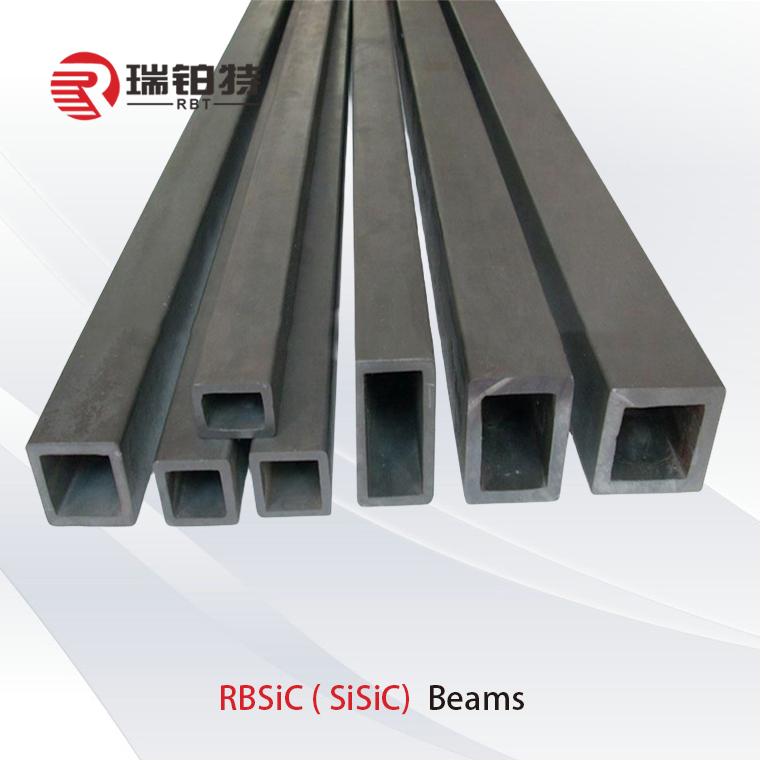

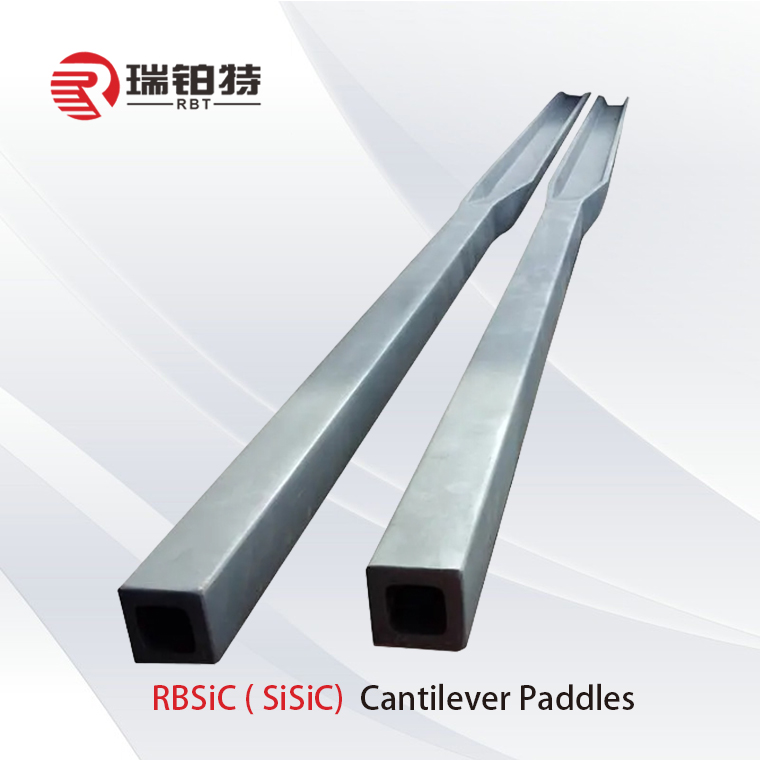

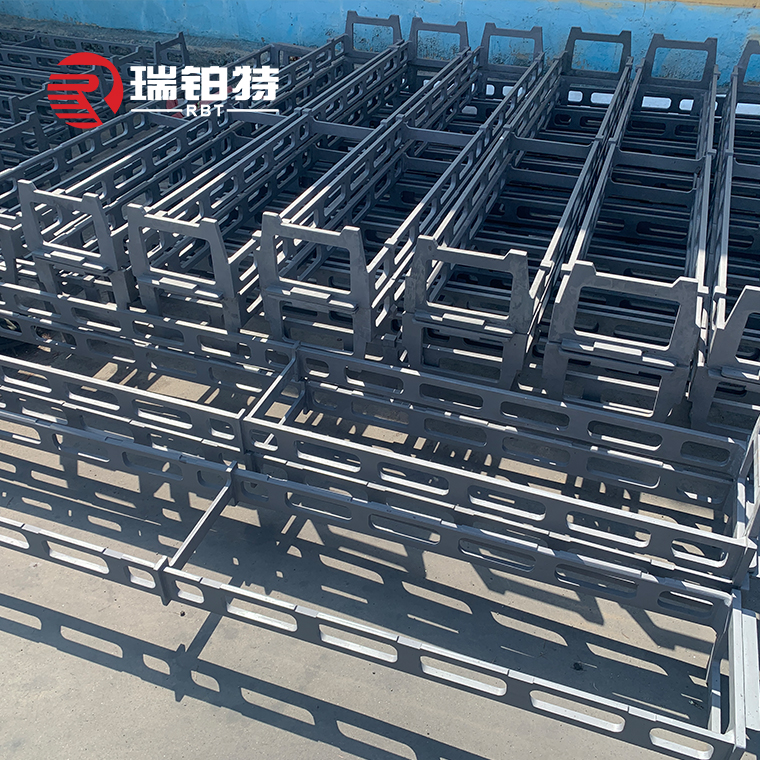

Uphawu:I-Silicon carbide square beam ineengenelo zomthamo omkhulu wobushushu obuphezulu, ukuhanjiswa kakuhle kwe-thermal, ukumelana nobushushu obuphezulu kunye nokonga amandla.Yeyona ndawo ifanelekileyo ye-lithium electric roller kiln, i-electronic ceramic powder, sanitaryware, i-ceramics yemihla ngemihla, i-porcelain yombane, izinto ezilahlayo, iiseramics ze-foam, kunye namanye amashishini.

| Ukuthwala uMmandla we-RBSic(SiSiC) Imiqadi | ||||||

| Ubungakanani beCandelo (mm) | Udonga Ukutyeba (mm) | Ulayisho olugxininisiweyo(kg.m/L) | Ukulayisha ngokulinganayo (kg.m/L) | |||

| B Icala | H Icala | W Icala | H Icala | W Icala | H Icala | |

| 30 | 30 | 5 | 74 | 74 | 147 | 147 |

| 30 | 40 | 5 | 117 | 95 | 235 | 190 |

| 40 | 40 | 6 | 149 | 149 | 298 | 298 |

| 50 | 50 | 6 | 283 | 283 | 567 | 567 |

| 50 | 60 | 6 | 374 | 331 | 748 | 662 |

| 50 | 70 | 6 | 473 | 379 | 946 | 757 |

| 60 | 60 | 7 | 481 | 481 | 962 | 962 |

| 80 | 80 | 7 | 935 | 935 | 1869 | 1869 |

| 100 | 100 | 8 | 1708 | 1708 | 3416 | 3416 |

| 110 | 110 | 10 | 2498 | 2498 | 4997 | 4997 |

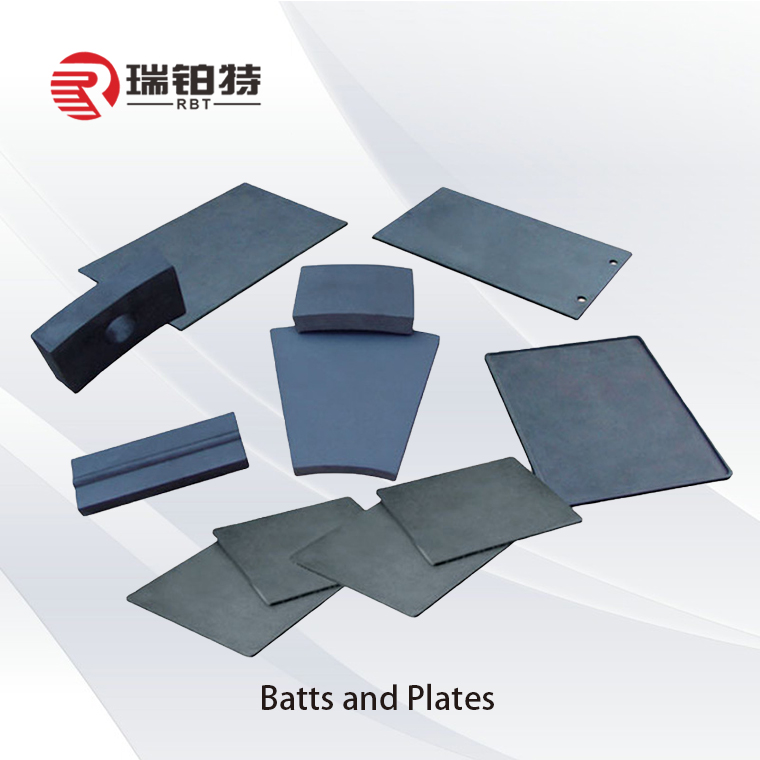

I-Burner Casing

Umbhobho weRadiation

Iiliner

Ixhasa

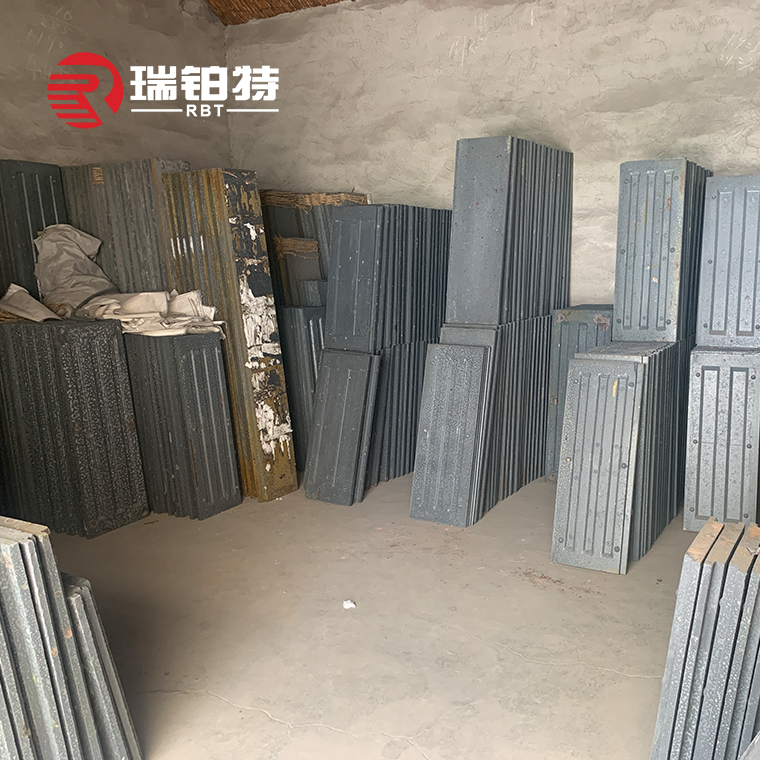

Package&Warehouse

Imibuzo ebuzwa qho

Dinga uncedo?Qiniseka ukuba undwendwela iiforam zethu zenkxaso ukuze ufumane iimpendulo kwimibuzo yakho!

Singumvelisi wokwenyani, umzi-mveliso wethu ukhethekileyo ekuveliseni izinto eziphikisayo iminyaka engaphezu kwama-30.Sithembisa ukubonelela ngexabiso elingcono, elona xabiso lilungileyo lokuthengisa kwangaphambili kunye nenkonzo emva kokuthengisa.

Kwinkqubo nganye yokuvelisa, i-RBT inenkqubo epheleleyo ye-QC yokwakheka kweekhemikhali kunye neempawu ezibonakalayo.Kwaye siya kuvavanya iimpahla, kwaye isatifikethi somgangatho siya kuthunyelwa kunye neempahla.Ukuba uneemfuno ezizodwa, siya kuzama konke okusemandleni ethu ukuze sizilungiselele.

Ngokuxhomekeke kubungakanani, ixesha lethu lokuhambisa lihlukile.Kodwa sithembisa ukuthumela ngokukhawuleza kunye nomgangatho oqinisekisiweyo.

Ngokuqinisekileyo, sinikezela ngeesampuli zamahhala.

Ewe, kunjalo, wamkelekile ukuba undwendwele inkampani ye-RBT kunye neemveliso zethu.

Akukho mda, sinokubonelela ngengcebiso kunye nesisombululo esilungileyo ngokwemeko yakho.

Senze izinto eziphikisayo iminyaka engaphezu kwe-30, sinenkxaso eqinile yobugcisa kunye namava atyebileyo, sinokunceda abathengi bayile ii-kilns ezahlukeneyo kunye nokubonelela ngenkonzo yokumisa enye.